1 safety end positions – Burkert Type 8793 User Manual

Page 27

27

Fluid connection

Type 8792, 8793

Procedure:

→

Apply supply pressure (1.4 – 7 bar) to the supply pressure con-

nection P.

For single-acting actuators (control function A and B):

→

Connect one working connection (A1 or A2, depending on

required safety end position) to the chamber of the single-acting

actuator.

Safety end positions see chapter“13.1.1”.

→

Seal a working connection which is not required with a plug.

For double-acting actuators (control function I):

→

Connect working connections A1 and A2 to the respective

chambers of the double-acting actuator

Safety end positions see chapter “13.1.2”.

Important information for perfect control behaviour!

This ensures that the control behaviour is not extremely

negatively affected in the upper stroke range on account of

too little pressure difference.

• keep the applied supply pressure at least 0.5 – 1 bar

above the pressure which is required to move the pneu-

matic actuator to its end position.

If fluctuations are greater, the control parameters measured

with the

X.TUNE function are not optimum.

• during operation keep the fluctuations of the supply

pressure as low as possible (max. ±10%).

13.1 Safety end positions

The safety end position following failure of the auxiliary electrical

power depends on the fluidic connection of the actuator to the

working connections A1 or A2.

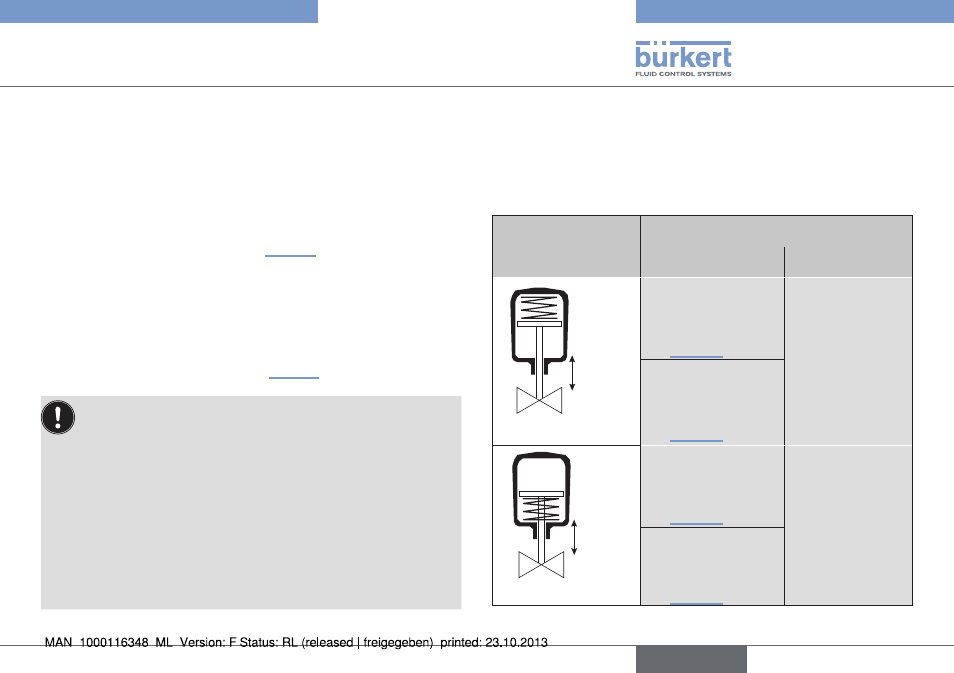

13.1.1 Single-acting actuators

Actuator system

Safety end positions after failure of the

electrical

auxiliary power

pneumatic

auxiliary power

up

down

down

→

Connection

according to

“Fig. 17”

down

up

→

Connection

according to

“Fig. 18”

Control function A

up

down

up

→

Connection

according to

“Fig. 17”

up

down

→

Connection

according to

“Fig. 18”

Control function B

Tab. 6: Safety end positions - single-acting actuators

english