Burkert Type 2301 User Manual

Page 31

31

Maintenance, cleaning

replace the control cone set

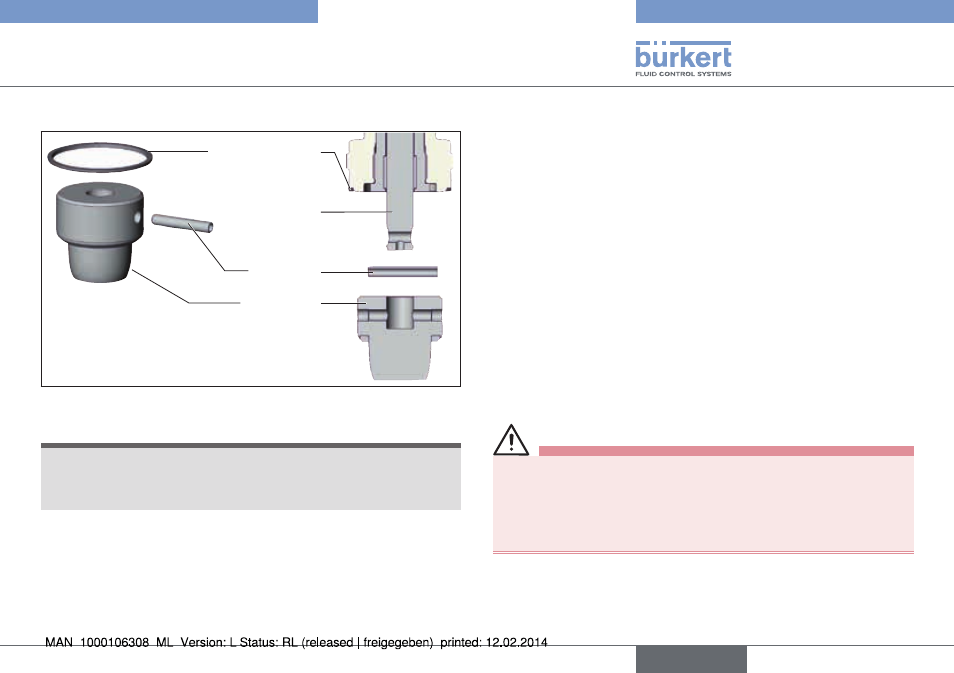

Spindle

Dowel pin

Control cone

Graphite seal

Fig. 18: Replacing the control cone set

note!

important information for the problem-free and safe functioning

of the device!

The sealing face of the control cone must not be damaged.

procedure:

→

Knock out dowel pin with a suitable pin punch.

pin punch ø 4 mm, for spindle diameter 10 mm

pin punch ø 5 mm, for spindle diameter 14 mm

→

Remove control cone.

→

Attach new control cone to the spindle.

→

Align bores of the control cone and spindle.

→

Support control cone on the cylindrical part with the aid of a

prism or something similar.

→

Put on dowel pin and carefully knock in with a hammer.

→

Position the dowel pin in the centre of the spindle axis.

install the actuator (with control unit) on the valve body

→

Check the graphite seal and if required, replace it.

Warning!

danger if incorrect lubricants used!

Unsuitable lubricant may contaminate the medium. In oxygen

applications there is a risk of an explosion!

▶ In specific applications, e.g. oxygen or analysis applications, use

appropriately authorised lubricants only.

→

Grease nipple thread before re-installing the actuator (e.g. with

Klüber paste UH1 96-402 from Klüber).

english

Type 2301