Brooks Instrument 5866M User Manual

Page 36

5-13

Troubleshooting

·

For a downstream controller P1 is the reference pressure. P2 is the

calibration pressure.

P1=P

Ref

P2=P

Cal

3. Determine the C

v

for the application. The ratio between P1 and P2 will

determine the calculation to use:

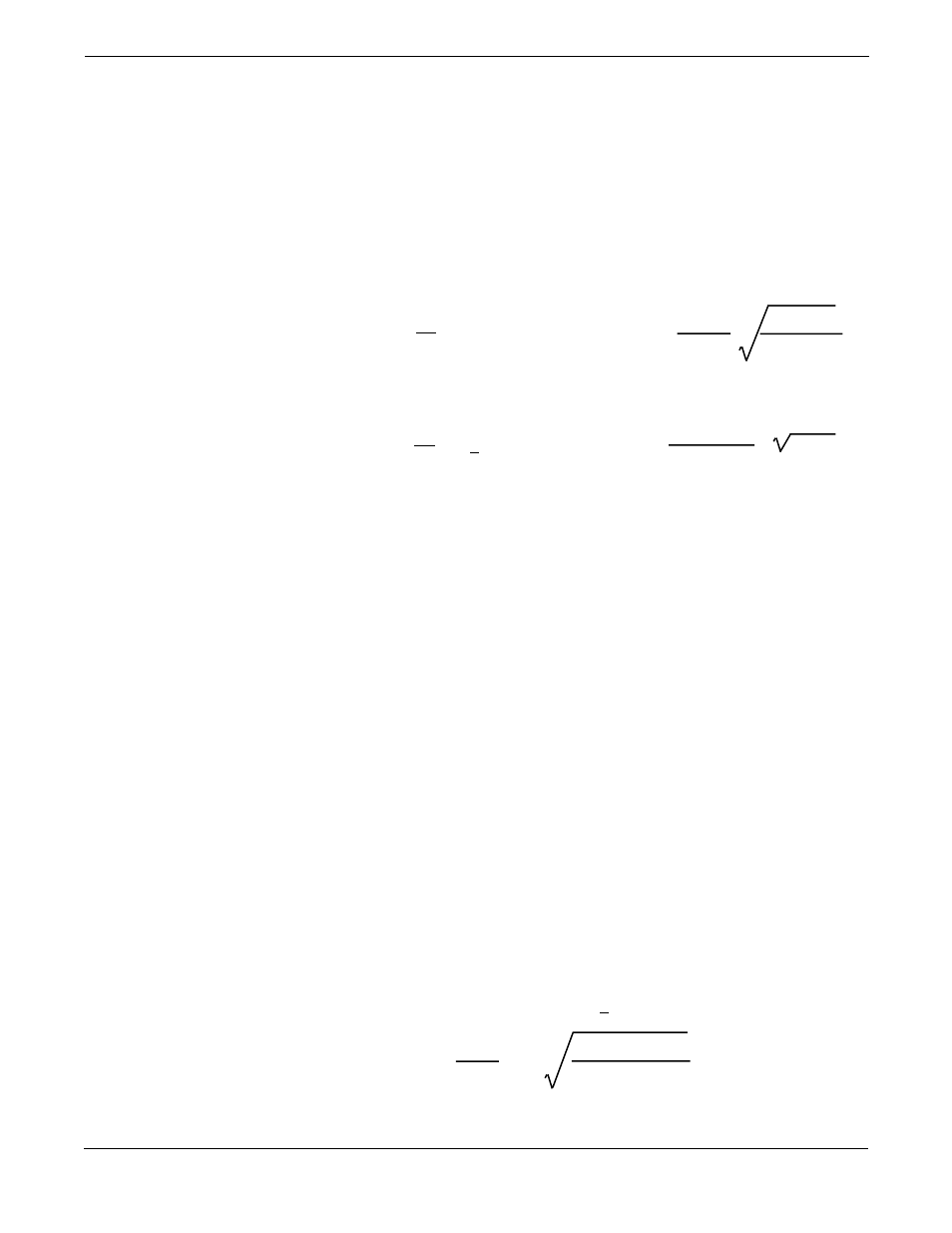

Equation #1

P2

Q

max

SG * T

If:

>

0.5 use: C

v

=

P1

800,000

(P1-P2) * P2

Equation #2

P2

Q

max

If:

<

0.5 use: C

v

=

SG * T

P1

397,000 * P1

4. Select the orifice size from Table 5-4 that has a C

v

just greater than the

C

v

determined in Step 3.

5. Check to see if the maximum operating pressure drop is greater than

the maximum allowable pressure drop for the orifice size selected. If the

pressure drop is too high for the orifice selected the instrument will not

be able to function correctly. This situation can be corrected by reducing

the pressure drop to the allowable level, or, reducing the maximum flow

so a smaller orifice will be selected.

An example Model 5866 application is shown in Figure 5-6 to illustrate

the orifice sizing procedure.

Given:

Controller Type: Upstream

Gas: 5/8 Nitrogen, 3/8 Hydrogen

Temperature; 70°F (530°R)

Maximum Flow: 800 sccm

Calibration Pressure: 100 psig (114.7 psia)

Reference Pressure; 1 atmosphere (14.7 psia)

Max Flow: 10 slpm (0°C ref. temp.)

Calculations:

SG Mixture = (3/8 x 0.070) + (5/8 x 0.964) = .629

Minimum Pressure Drop = 114.7 x .05 = 5.7 psi

Maximum Pressure Drop = 114.7 - 14.7 = 100 psi

P1 = 14.7 + 5.7 = 20.4 psia

P2 = 14.7 psia

P2/P1 = 14.7/20.4 = 0.721 which is > 0.5 therefore use equation #1

800

0.629 x 530

C

v

=

=

2.0 x 10

-3

800,000

(20.4 - 14.7) x 14.7