Table 5-2), En in table 5-2. if an, 3 troubleshooting table 5-1. bench troubleshooting – Brooks Instrument 5866M User Manual

Page 26: Table 5-2. sensor troubleshooting

5-3

Troubleshooting

Table 5-1. Bench Troubleshooting.

Trouble

Possible Cause

Check/Corrective Action

Output stays at zero Volts regardless of com- Defective Sensor

Replace sensor. Refer to Section 5-3 and Table 5-2.

mand and there is pressure on the controller.

Output stays at zero Volts regardless of

Clogged Control Valve

Check Pin 7 if the voltage is more than +11 V. Disassemble and repair the control valve.

command and there is no flow through the

Refer to Sections 5-3 and 5-4.

controller.

-15 V applied to the valve override input.

Check valve override input. Refer to Figure 2-2 for terminal assignments.

Defective printed circuit board.

Replace printed circuit board. Refer to Sections 5-3 and 5-4.

Output signal stays at +14 V. regardless of

Valve stuck open or leaky.

Clean and/or adjust control valve. Refer to cleaning procedure and/or Section 5-5.

command and there is flow through the

controller.

+15 Vdc applied to the valve override input.

Check the valve override terminal. Refer to Figure 2-2 for terminal assignments.

Defective printed circuit board

Replace printed circuit board. Refer to Sections 5-3 and 5-4.

Command input floating.

Connect command signal. Refer to Figures 2-1 and 2-2 for terminal assignments.

Output signal follows setpoint at higher

Leaky control valve.

Disassemble and repair valve. Refer to Sections 5-3 and 5-4.

commands but will not go to zero.

Excessive resistance in valve voltage return

Reduce wiring resistance

line.

Output signal follows setpoint at lower

Insufficient inlet pressure or pressure drop

Adjust pressures, check calibration. Refer to Section 5-1.

commands but does not reach full scale.

Partially clogged valve.

Disassemble and repair control valve. Refer to Sections 5-3 and 5-4.

Valve out of adjustment.

Adjust valve. Refer to Section 5-5.

Valve guide spring failure.

Controller oscillates (see below)

Controller oscillates.

Pressure drop or inlet pressure excessive.

Adjust pressures.

Oversized orifice

Check orifice size. Refer to Section 5-6 and Table 5-4.

Valve out of adjustment.

Adjust valve. Refer to Section 5-5.

P/I adjustment not correct.

Adjust P/I potentiometers. Refer to Section 3-2.

Faulty pressure regulator.

Check regulator output.

Defective printed circuit board

Replace printed circuit board. Refer to Sections 5-3 and 5-4.

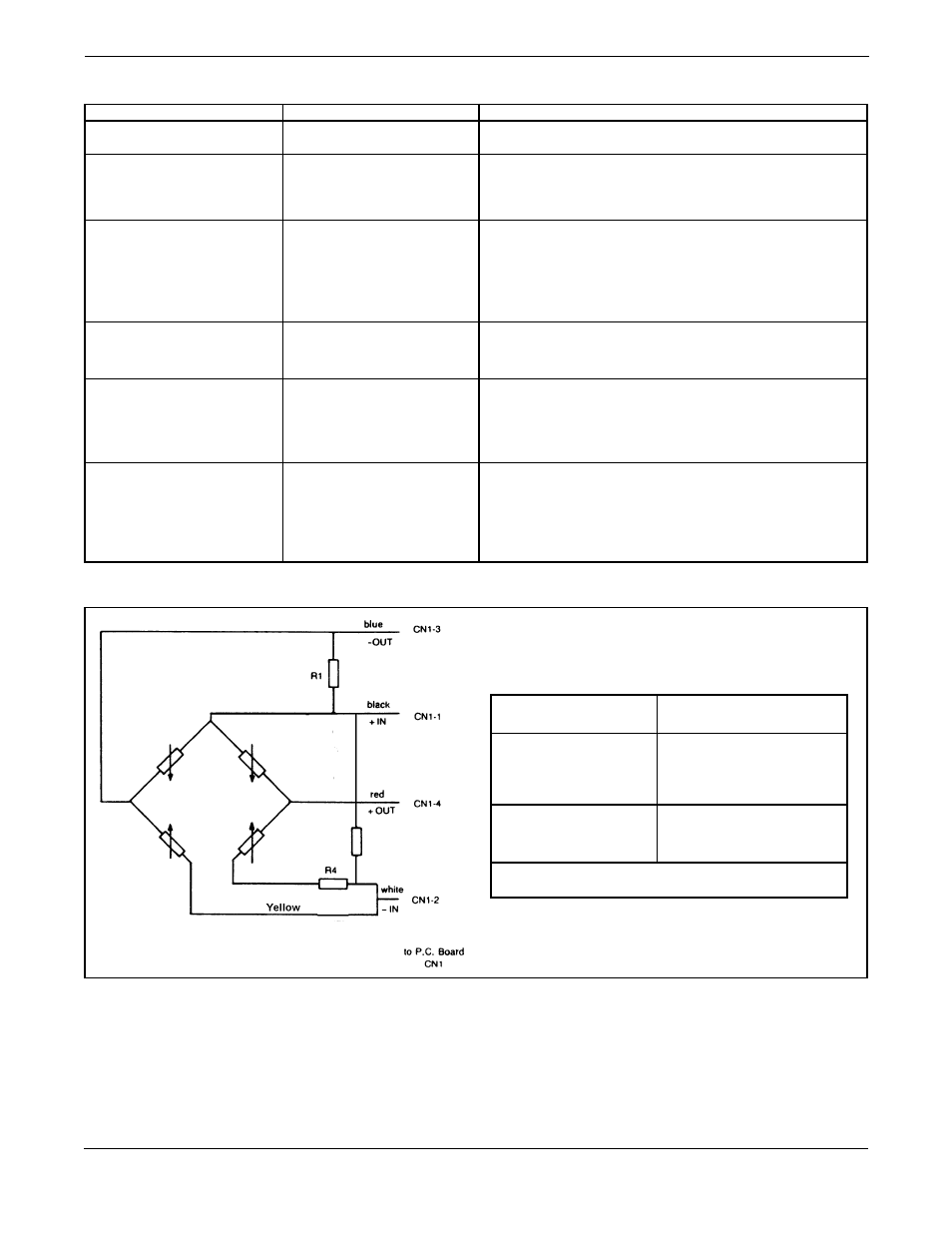

Table 5-2. Sensor Troubleshooting.

OHMMETER

RESULT IF ELECTRICALLY

CONNECTION

FUNCTIONAL

4 Sensor wires to body

Open circuit on Ohmmeter.

(ground)

If one of these is shorted,

(Pin 1 to 4 to body)

an Ohmmeter reading will

be obtained.

Between the different

Minimum 1 k Ohm

wires

Maximum 4 k Ohm

Depending on sensor used

NOTE: Remove the sensor connector from the P.C. board

for this procedure.