2 adjustment test setup -7, Caution – Brooks Instrument 5866M User Manual

Page 30

5-7

Troubleshooting

The valve is adjusted in Brooks pressure controllers by adding spacers (9

and 10) to the control valve to vary the initial position of the parts. The

proper initial position is required so the valve will have the proper travel

and force available to insure reliable control. Screw type adjustments are

not used in Brooks control valve since they can change with pressure and

vibration. Screw type adjustments also introduce a dynamic seal that is a

potential leak site and source for contamination.

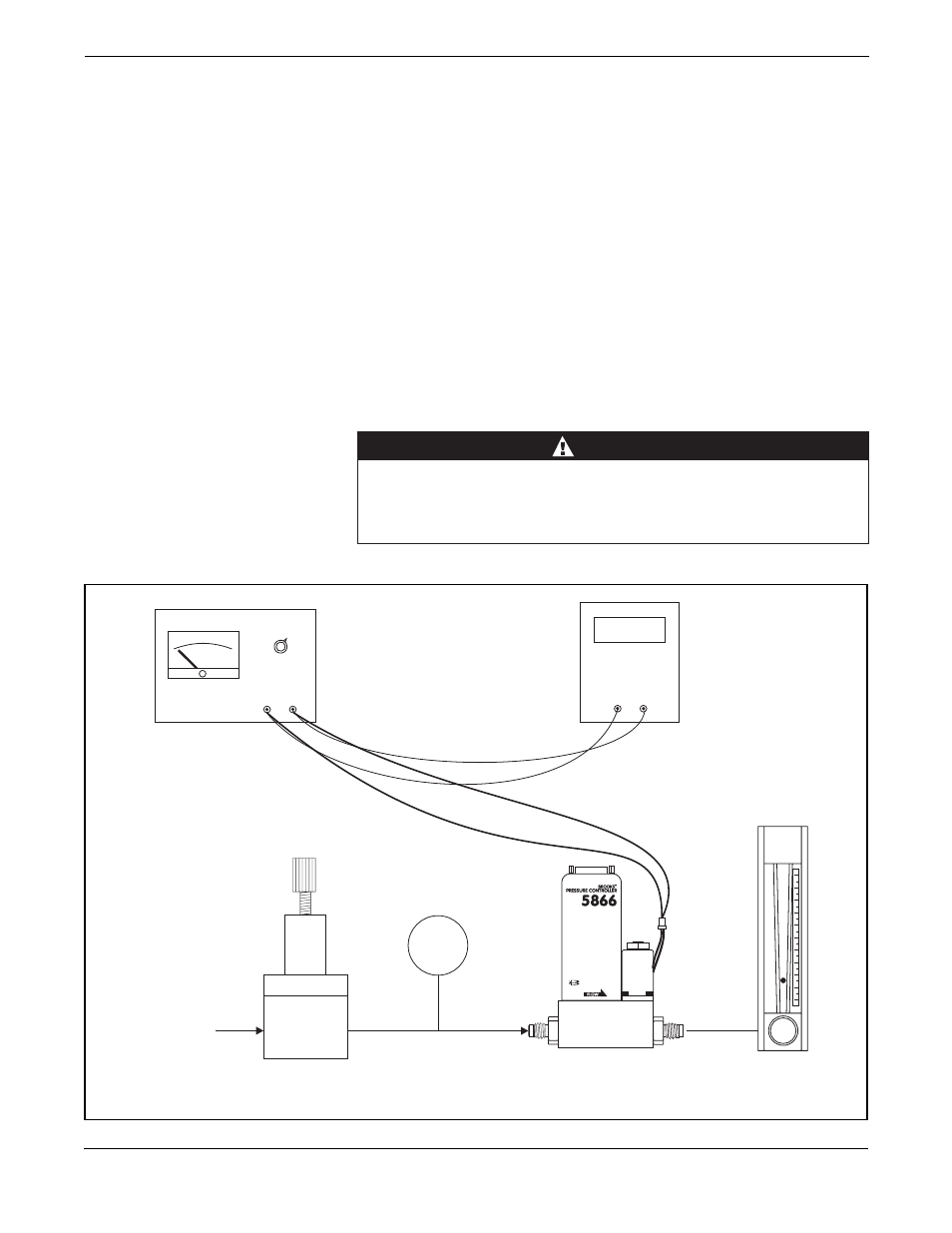

The adjustment procedures below require the use of a variable voltage

power supply, pressure regulator, pressure gage, voltmeter, flow meter and

a supply of nitrogen or air. The test set up is shown in Figure 5-2. The

power supply must be capable of delivering 400 mA at 30 V. If the proper

equipment or facilities are not available to perform this procedure, please

return the instrument to the factory or an authorized repair station. Refer to

Figure 7-1 for the location of the parts. Section A describes the adjustment

of the Normally Closed control valve, Section B describes the adjustment

of the Normally Open control valve. Please refer to the proper section for

your valve type.

When testing upstream type pressure controllers, be certain not to

exceed the maximum overpressure specification for the pressure

transducer installed, as specified in Section 1-4. For the 0-1 bar

transducer this is only 7 psig!

CAUTION

Figure 5-2. Adjustment Test Setup.

®

Model 5866

Pressure

Regulator

Pressure

Gage

Variable

Power Supply

Nitrogen

or Air

Voltmeter

Flow Meter

P

+

-

+

-