Starting line leak tests 4, Note 4 – Franklin Fueling Systems Tank Sentinel (TS-1001, 2001, 504, 508 & 750) Operators Guide Rev. D User Manual

Page 72

4

Page

4 - 6

Tank Sentinel Operator’s Guide

Starting Line Leak Tests

When a Line Leak Test Fails / Line Leak is Detected

The TS-LLD line leak detection system disables the Submerged Turbine Pump (dispensing

stops / is not allowed), the red Alarm light is flashed, and a flashing

ALARM

is displayed

under the LINE column, and an alarm report will printout.

Automatic testing and reporting

is possible when one or more INCON TS-LLD line leak detectors are interfaced to the tank

gauge by the

TS-LLDI

interface.

CAUTION

Don’t excavate / repair a line because of a single failed leak test.

Confirm the presence of a leak before attempting any repairs !

Leak tests occasionally fail when no leaks actually exist because of: product line

instability, thermal contractions within the line, or because of a pump / vapor recovery

system malfunction. Air trapped within the line may also cause false leak alarms (this is

especially true after new installations / maintenance / service).

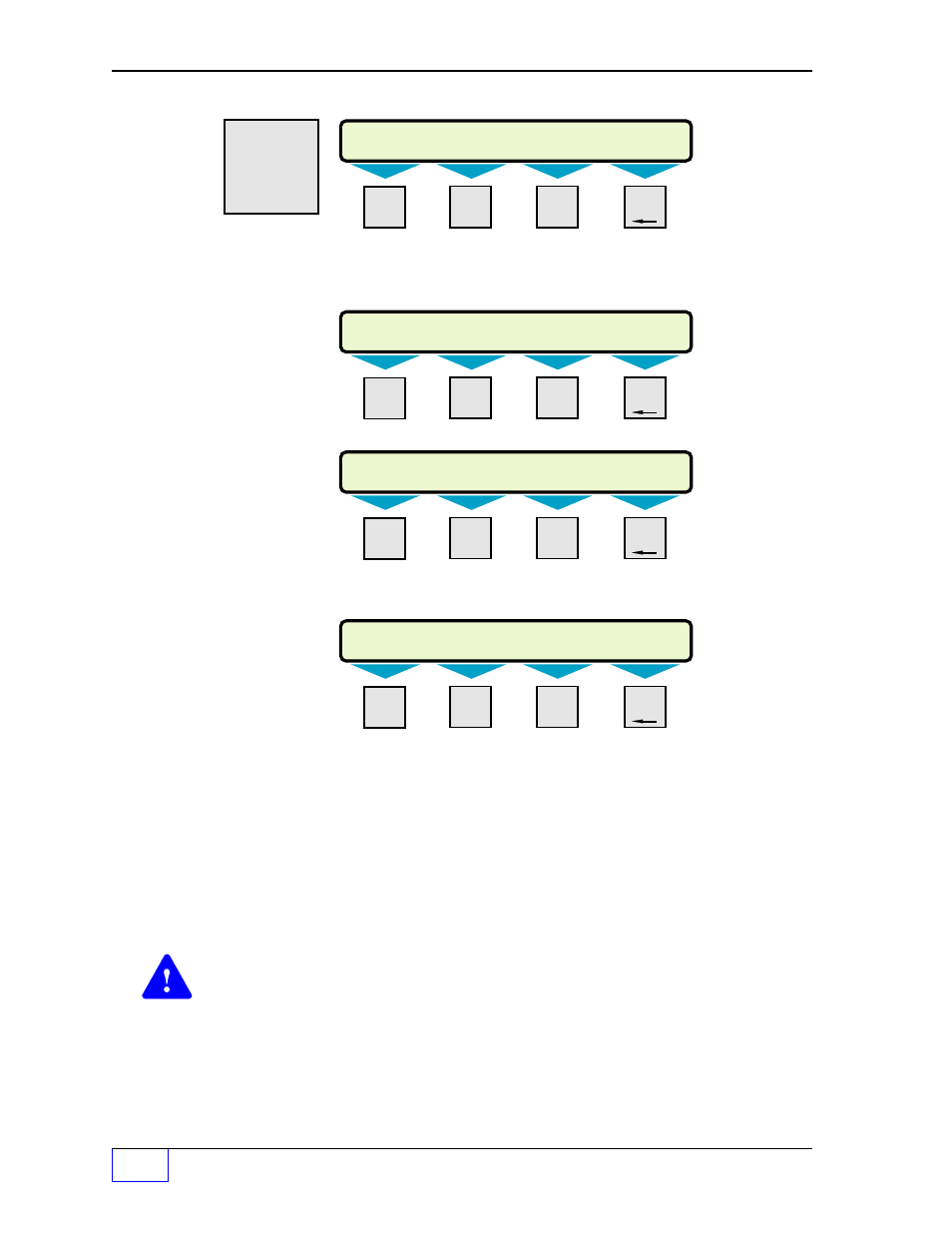

1) Press the

TEST

key and then the

M2

key (above)

2) Choose the type of test below (press a

menu key

)

...choices are the 0.1 gph or 0.2 gph leak tests:

3) Choose the Line # (press a

menu key

below)

4) or press

DOWN

and the

menu key

key under the

word ALL to choose ALL lines

NOTE

☞

L

Y

TEST

0

SELECT LEAK TEST OPTION

STATUS

START

ABORT

M1

M2

M3

M4

LEFT

RIGHT

SELECT LEAK TEST TO START

0.1 TANK

0.2 TANK

0.1 LINE

0.2 LINE

M1

M2

M3

M4

LEFT

RIGHT

SELECT LINE TO START 0.N TEST

(MORE)

LINE 1

LINE 2

LINE 3

LINE 4

M1

M2

M3

M4

LEFT

RIGHT

SELECT LINE TO START 0.N TEST

(MORE)

ALL LINES (N = 0.1 or 0.2 gph Line Test)

M1

M2

M3

M4

LEFT

RIGHT