Error detection and elimination – Elmo Rietschle 2FC4...-1CB User Manual

Page 62

8

Error detection and elimination

610.00260.40.000 · 05.2014

62

/

74

© Gardner Denver Deutschland GmbH

List of errors and system errors

When an error occurs, the inverter switches off; for the corresponding error num-

bers, refer to the flash code table or the PC tool.

Error messages can only be acknowledged when the error is no longer pre-

sent.

!

Error messages can be acknowledged as follows:

1. Digital input (programmable)

2. via the hand-held unit MMI

3. Automatic acknowledgement (parameter 1,181)

4. Switching the device on and off

5. via fieldbus (CANOpen, Profibus DP, EtherCAD)

Below is a list of possible error messages. For errors not listed here, please con-

tact the manufacturer.

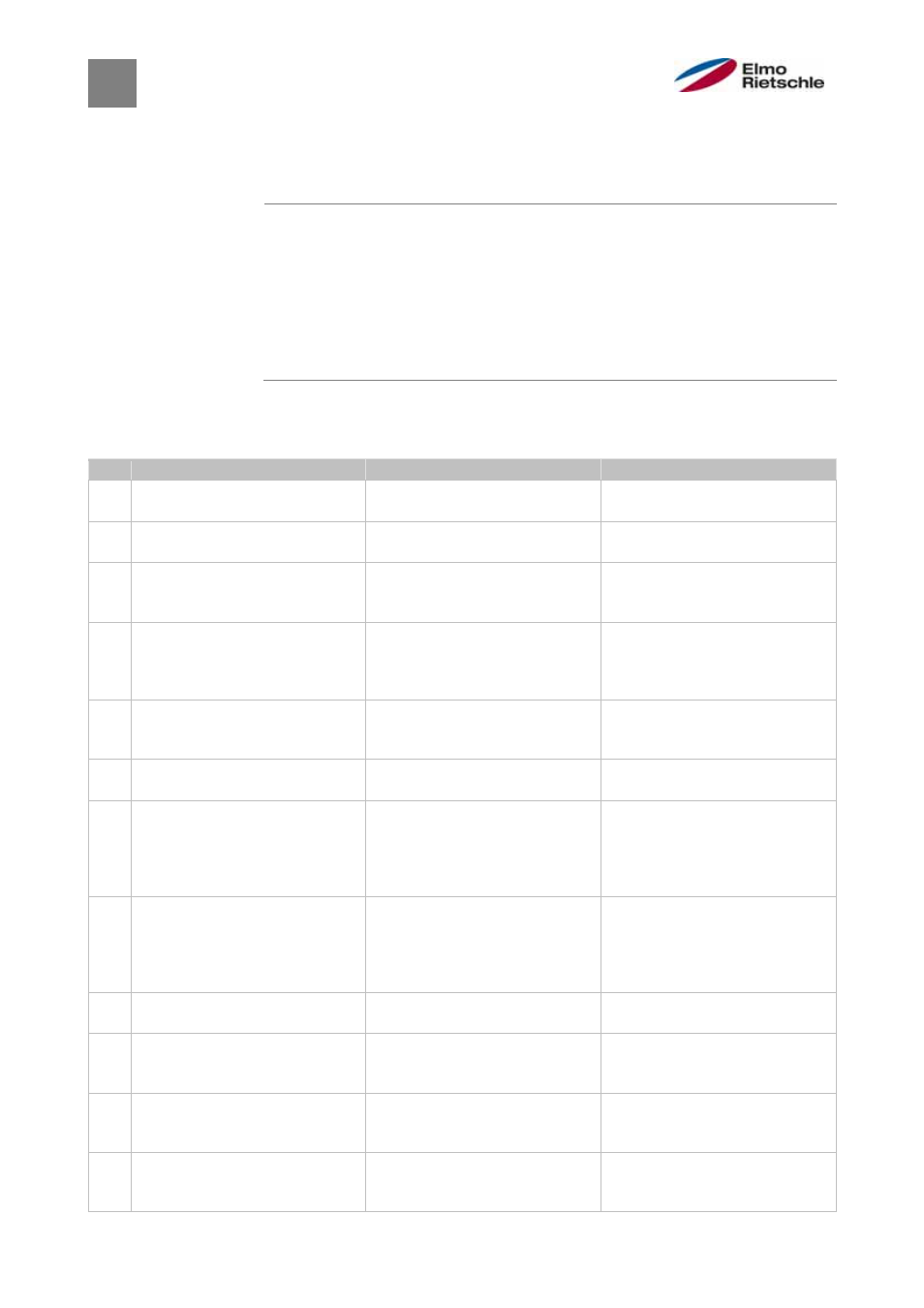

Error detection

No. Error name

Error description

Possible cause / remedy

1

Low voltage 24 V application

Supply voltage of the applica-

tion is less than 15 V

Overload of the 24 V supply

2

Over-voltage 24 V application

Supply voltage of the applica-

tion is greater than 31 V

Internal 24 V supply is not OK or

external power supply is not OK

3

Version error of client PLC

The version of the client PLC

does not match the device

firmware

Check the version numbers of

the customer PLC and device

firmware

4 Communication

applica-

tion<>performance

The internal communication

between the application and

power printed circuit board is

out of order

EMC interference

5 Parameters

distributor

The internal distribution of the

parameters during the initialisa-

tion has failed

Parameter set is incomplete

6 Timeout

performance

The

power unit does not re-

spond

Operation with 24 V without

power supply

7

Cable breakage analogue input

1 (4 - 20 mA / 2 - 10 V)

Current or voltage is less than

the lower limit of the analogue

input 1 (this error monitoring is

activated by setting the parame-

ter 4,021 to 20%)

Cable breakage, defective ex-

ternal sensor

8

Cable breakage analogue input

2 (4 - 20 mA / 2 - 10 V)

Current or voltage is less than

the lower limit of the analogue

input 2 (this error monitoring is

activated by setting the parame-

ter 4,021 to 20%)

Cable breakage, defective ex-

ternal sensor

9

Blocking detection

The drive shaft of the motor is

blocked. 5.080

Remove blockage

10

Overtemperature of drive con-

troller application

Internal temperature too high

Insufficient cooling, low speed

and high torque, clock fre-

quency too high

11

Bus timeout

No response from the bus de-

vice or HAND-HELD UNIT MMI /

PC

Check bus wiring

12 Confirmation

error

The number of max. automatic

acknowledgements (1,182) has

been exceeded

Check the error history and

eliminate errors

8.2