Bell & Gossett S14333 Technologic 5500 Series ZoneSav Controller User Manual

Page 25

25

The following is a description of the hardware, diag-

nostics, and corrective action to maintain a process

being controlled by the ZoneSav controller.

Note: The following should not be interpreted as the

maximum configuration of this controller; rather this

describes its application as a ZoneSav controller

only.

5.1

Technical Overview

The ZoneSav Controller is a micro-processor based

valve controller unique to and exclusively manufac-

tured by ITT Bell & Gossett. All aspects of this unit

are strictly proprietary to ITT Bell & Gossett.

5.2

Digital Inputs

The controller has provision for digital inputs with an

operating voltage of 24 VDC. This signal voltage

must be obtained from the 24 VDC power supply

mounted to the subpanel. It is not recommended

that other power sources be used without factory

approval. Customer connections are made directly

to the terminal blocks tied to the digital input module.

5.3

Digital Outputs

The controller has provision for relay outputs to con-

trol 120 V 50/60 HZ devices. The relays are not

removable. If defective, the digital output module

must be returned to the factory for repair. All relays

operate as single pole single throw. Components are

provided to reduce contact arc and extend electrical

life. Customer connections are made directly to the

terminals mounted on the digital output module.

5.4

Analog Inputs

Analog inputs are provided for process variables and

optional transmitters. All analog inputs operate at

4-20mA. They must be powered from the 24 VDC

power supply included with the controller.

5.5

Memory

The logic is stored in a non-removable EEPROM chip

which can be updated from the RS-232 program port

on the CPU or from a memory card. The user setup

data is stored in non-volatile memory or fixed RAM.

The fixed RAM requires power to hold the informa-

tion. While the controller is powered up, the CPU

controller provides the power to save the user values.

When the controller is powered down a 3V Lithium

battery provides the power to store the user values.

When the battery voltage drops below 2.5 VDC the

controller will display ALRM. After pressing the HELP

key the display will indicate Battery!. You will have

approximately 25 weeks to replace the battery before

losing memory due to an under voltage condition

during a power loss.

5.6

CPU

The CPU does not require any maintenance, and it

cannot be replaced as a field repair.

5.7

Power Supply

The power supply provides 24 VDC for all digital and

analog signals as well as the CPU. It is specifically

rated only for the controller and other loads should

not be applied without factory approval.

5.8

Protection

Analog inputs - the analog inputs provided on the

ZoneSav Controller must be wired according to the

wiring diagram that shipped with the unit.

Protection - all analog inputs are protected from high

voltage, crossed wiring, etc. A sustained fault will be

limited to 20mA by the current limiting circuit.

Digital Inputs - as long as input power is derived from

the integral 24VDC power supply they are protected.

Digital Outputs - each output shall not exceed the

ratings on the digital output module.

5.9

Instruments and their Use

With the diagnostics described herein, extensive

instruments are not required. However, the instru-

ments used should be quality units to meet the fol-

lowing at a minimum.

Under no circumstances shall any instrument be

used to test any on board components. Especially

risky is an ohmmeter with battery voltage higher than

TTL logic or applied with incorrect polarity.

5.9.1

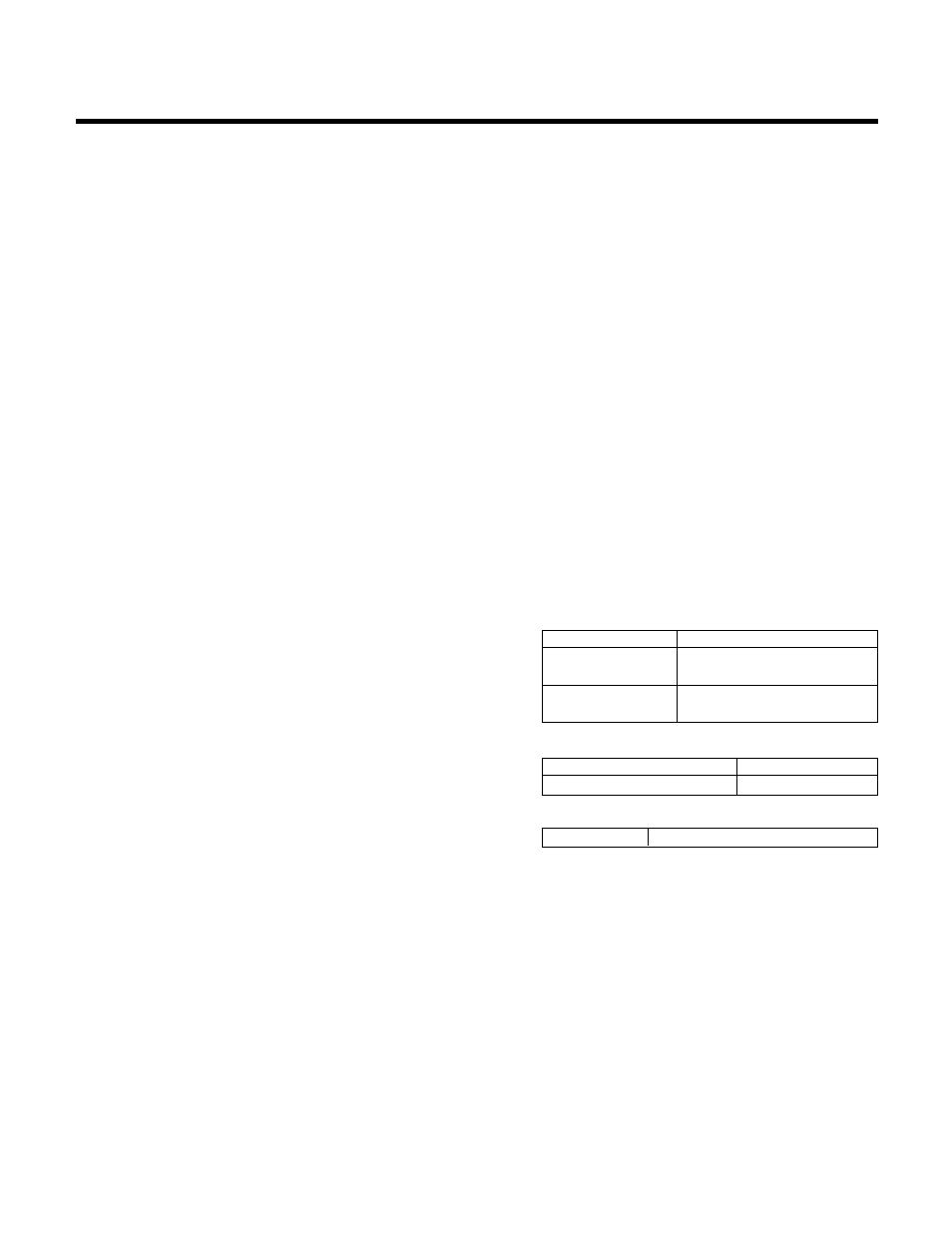

AC/DC Voltmeter

Input impedance

Not less than 10 MEGOHM.

Accuracy

- AC ± 2% of Full Scale

- DC ± 3% of Full Scale

Rated circuit to

1000V.

ground voltage

5.9.2

Ohmmeter

Accuracy

± 2.5%

Max open circuit voltage

0.5 V

5.9.3

Milliamp Meter

Accuracy

± 2% of Full Scale

5.9.4

Signal Generator (analyzer) - recommended

The following signal generators are recommended:

Beta calibrator Model 434 20mA signal analyzer,

Altek calibrator Model 334 4-20mA loop analyzer or

Druck UPS III loop calibrator. The instruments may be

purchased from a Local Process Control Distributor.

Note: If some other instrument is used it must float

above ground, preferably battery powered.

Section 5 - Maintenance