GE Industrial Solutions GERAPID 2508, 4008, 5008, 6008 WITH ARC CHUTE 1X2 User Manual

Page 46

46

Design and specifications are subject to change without notice

S47183De rev.02 2011-03-14

6.1.5 Inspection of contacts’ tilt and gap

Pay attention to the warnings, Section 1!

A) Remove the arc chute and adapter

See 6.1.4-A/B.

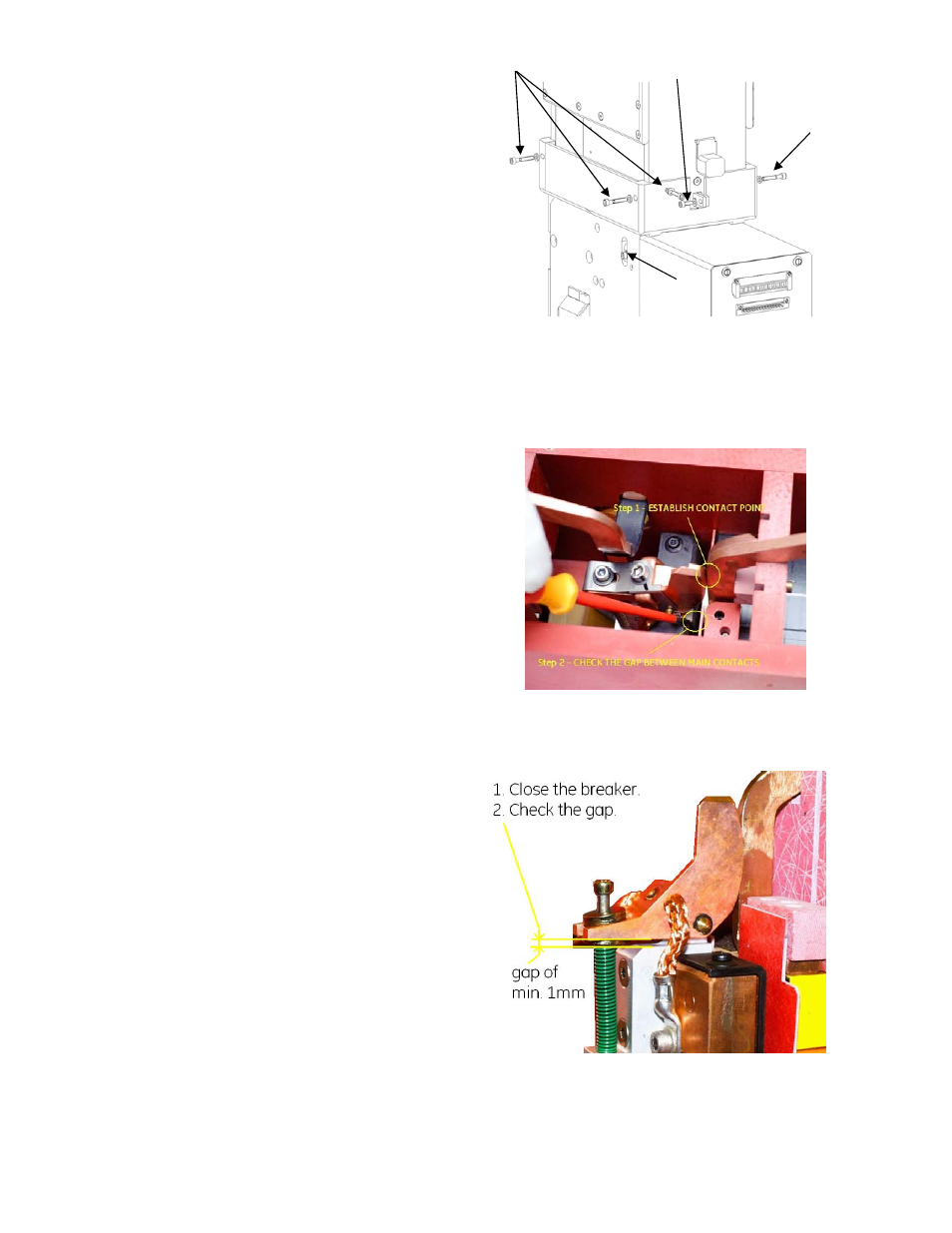

B) Check the tilt of the main contacts

[Fig. 40]. Use the hand lever for slowly closing the main

contacts.

[Fig. 46]. Once the arcing contact touches arc runner, check

the air gap between main contacts. The gap between main

contacts shall have more than 1 mm [0.04 in].

In case of insufficient tilt (gap), replace the arcing contact

with new one. See 6.2.1 and 6.2.2 for details.

If required gap is not available, even after component

replacing, please contact GE Service Team.

C) Check the air gap of arcing contact

Close the breaker and secure the solenoid drive against

unintended opening.

See 1.2.1.

[Fig. 47]. Check the air gap between the arcing contact and

main arm. It shall be minimum 1 mm [0.04 in].

In case of insufficient gap, replace the arcing contact with

new one. See 6.2.1 and 6.2.2 for details.

If required gap is not available, even after contact

replacing, please contact GE Service Team.

D) Reinstall back adapter and arc chute

See 6.1.4-G/H.

6.1.6 Inspection of the screw connections

Pay attention to the warnings, Section 1!

[Fig. 45]. Tighten front and backside of the arc runner screw

connections (2) and (5). Use torque of 10 Nm [88 in-lbs].

[Fig. 45]. Tighten arc chute connections (3). Use torque of

5 Nm [44 in-lbs].

[Fig. 45]. The arc runner’s screw connections (2) must be

secured by means of lock washer.

[Fig. 45]. The arc chute’s screw connections (3) must be

secured by means of flat washer.

Any other screws shall be tightening with applied torques

from Table 6.1.

Ensure that the screws are in good condition, that thread

and nest are not damaged. Surface shall be free from rust.

Replaced any screw, which does not fulfill above conditions.

This check must be carried out prior to commissioning and

after maintenance.

6.1.7 Inspection of the mechanical components

Only GE Service Team or its representative shall perform this

inspection. These require major disassembly and adjustment

of the breaker. Customer, without supervision of trained

specialist, shall not execute these.

Fig. 45 Inspecting screw connections

Fig. 46 Inspection of the main contacts’ tilt

Fig. 47 Inspection of the arcing contact’s air gap

3

5

3

2