GE Industrial Solutions GERAPID 2508, 4008, 5008, 6008 WITH ARC CHUTE 1X2 User Manual

Page 44

44

Design and specifications are subject to change without notice

S47183De rev.02 2011-03-14

6.1.1 General visual inspection

Check out for damages or cracks of the frame, the adapter

or the arc chute.

Check out the black marks on the countersunk screws.

These marks shall be aligned together. If any screw is

loosening, shall be replaced with new one, using Loctite

222. Afterwards, mark the screw with black line to sign its

position in nest.

Check out for missing screws or caps.

Check out for damaged labels. Clean and repair.

Check out for corrosion. In case of significant corrosion,

please contact GE representative for assistance.

Check out for distinct manifestations of flame or smoke at

the frame. Especially in lower area of the breaker. Please

document and contact GE representative for assistance.

Clean the breaker of dirt and dust. Remove all dirt with a

dry cloth. No particularly high signs of abrasion (rough

chips) should be visible anywhere.

Clean and degrease the copper terminals.

6.1.2 General functional inspection

Pay attention to the warnings, Section 1!

In order to check the latch mechanism, the breaker can be

opened and closed with a hand lever.

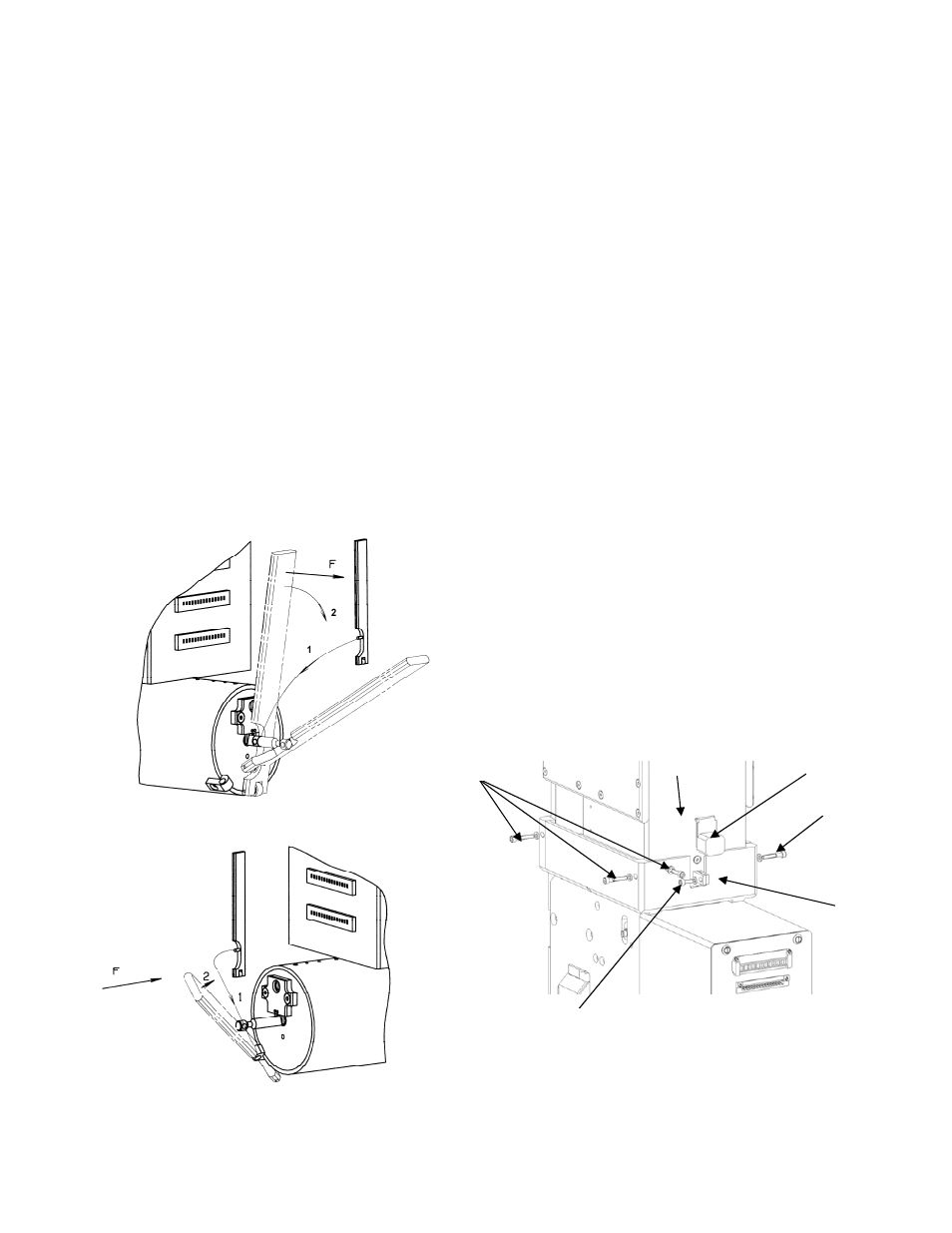

Fig. 40 Using of the hand lever

Re-energize the control circuits and switch the breaker ON

and OFF several times using ST or UVR, and using closing

drive. The contacts must close after the CLOSE command

and must open following the OPEN command

The breaker mechanism must not appear sluggish nor

must ON/OFF be unduly delayed.

6.1.3 Inspection of the arc chute

Pay attention to the warnings, Section 1!

A) Remove the arc chute

[Fig. 41]. Remove front and rear arc runner protection caps

(1) by sliding up and out.

[Fig. 41]. Using SW5 hex wrench, remove front and rear arc

runner screws (2). Remove the six arc chute attachment

screws (3) from front, rear and sides of the adapter (4). Lift

arc chute (5) up and out of the adapter.

B) Check the arc chute

[Fig. 42]. Check the arc chute’s interior, as far as possible,

for deposits (1). There should be no copper pearls on the

metal-plates, which could partially short the plates.

[Fig. 42]. Check the general condition of the insulation

plates (4). These shall not be bent or burned. Also other

insulation shall not be heavily damaged.

[Fig. 42]. Check the arc horns (2). The cross section shall not

be reduced more than ~30 %.

[Fig. 42] Check the splitting plates (3). These shall not be

burned more than ~20 mm [~0,8 in].

C) Install the arc chute

[Fig. 41]. Put arc chute (5) into adapter (4).

[Fig. 41]. Tighten front and backside connections of the arc

runners (2), including lock washer. Use a torque of 10 Nm [88

in-lbs].

[Fig. 41]. Tighten front, rear and side of the arc chute

connections (3), including flat washers. Use a torque of 5 Nm

[44 in-lbs].

[Fig. 41]. Put on isolation caps (1).

Fig. 41 Removing the arc chute

2

1

3

5

4

3