4 mounting, 1 general instructions, 4mounting – VEGA VEGADIF 55 4 … 20 mA_HART User Manual

Page 11

4

Mounting

4

.1 General instructions

M

ake sure that the wetted parts of VEGADIF 55, especially the seal

and process fitting, are suitable for the existing process conditions

such as pressure, temperature etc. as well as the chemical properties

of the medium.

Y

ou find the specification in the "Product information manual"

VEGADIF

55

in chapter "Technical data".

S

elect such a mounting position that the instrument is in easy reach

when mounting or connecting as well as for later retrofitting of the

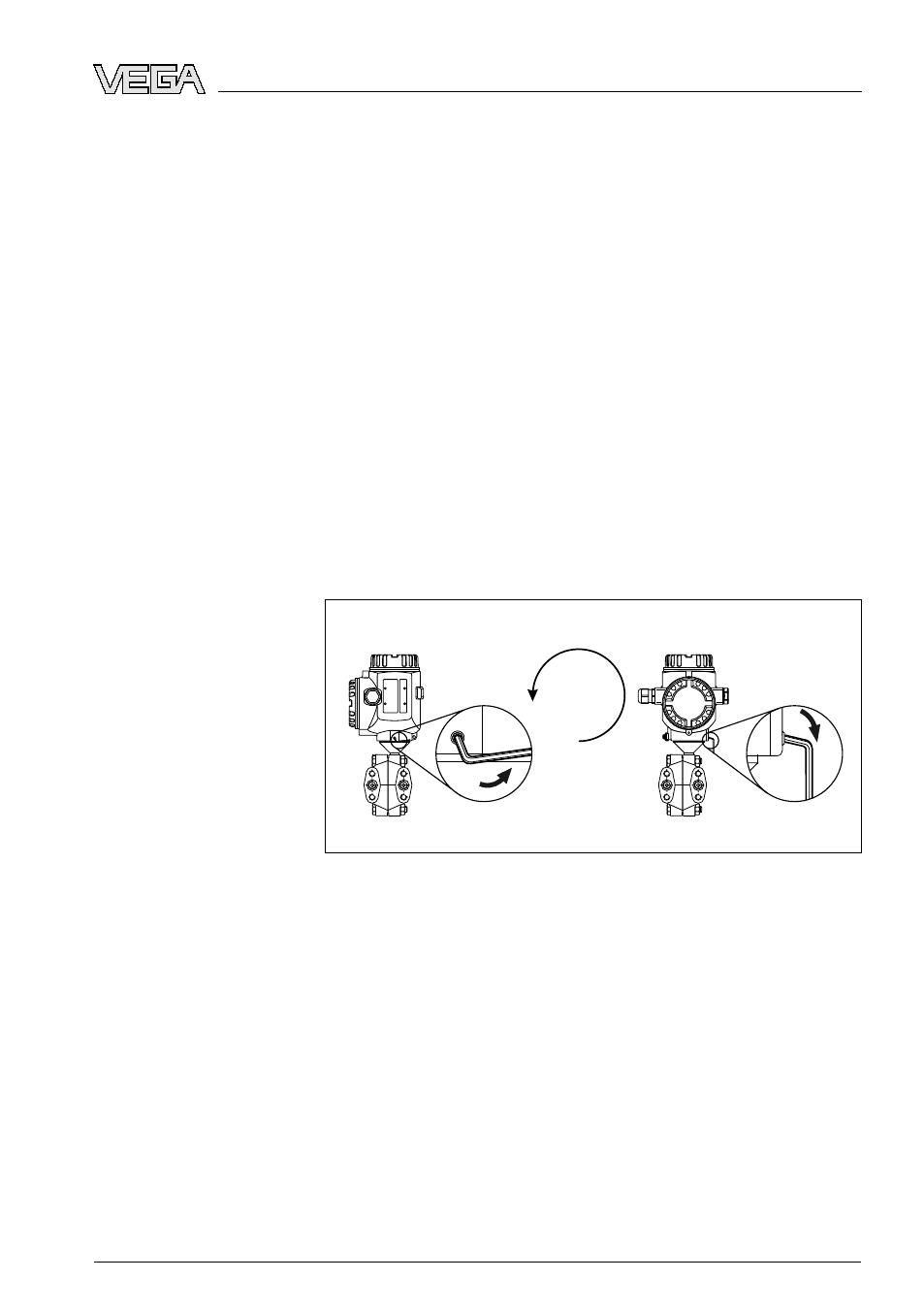

indicating and adjustment module. After loosening the pin, the housing

can be rotated by 380°.

P

roceed as follows:

1

L

oosen the pin with a 2 mm Allen wrench

2

R

otate the housing (max. up to 380°)

3

T

ighten the pin

max. 380°

Fig. 4: Direct the housing

D

ue to the installation position of VEGADIF 55, a zero point shifting

can be caused, i.e. the measured values is not zero with empty vessel.

Y

ou can correct this zero point shoft either directly on the instrument

via the "E" key or the remote adjustment, see chapter "Operating

elements"

and "Position adjustment".

Y

ou find general recommendations for wiring of effective pressure

lines in DIN 19210 "Effective pressure lines for flow systems" or the

corresponding national or international standards. When wiring

effective pressure lines outdoors, keep in mind to use a suitable

antifreeze, e.g. by using tube heat tracing. Wire effective pressure

lines with a monotonic decrease of at least 10 %.

U

sing a three-fold or five-fold valve block ensures easy setup,

mounting and maintenance without interrupting the process.

Materials, wetted parts

Mounting position

Installation position

Effective pressure lines

Valve block

VEGADIF

55 • 4 … 20

mA/HART

11

4 M

ounting

31731

-EN

-081119