Vegacom 557 with vvo or vv – VEGA VEGACOM 557 Modbus protocol User Manual

Page 7

VEGACOM 557 Modbus

7

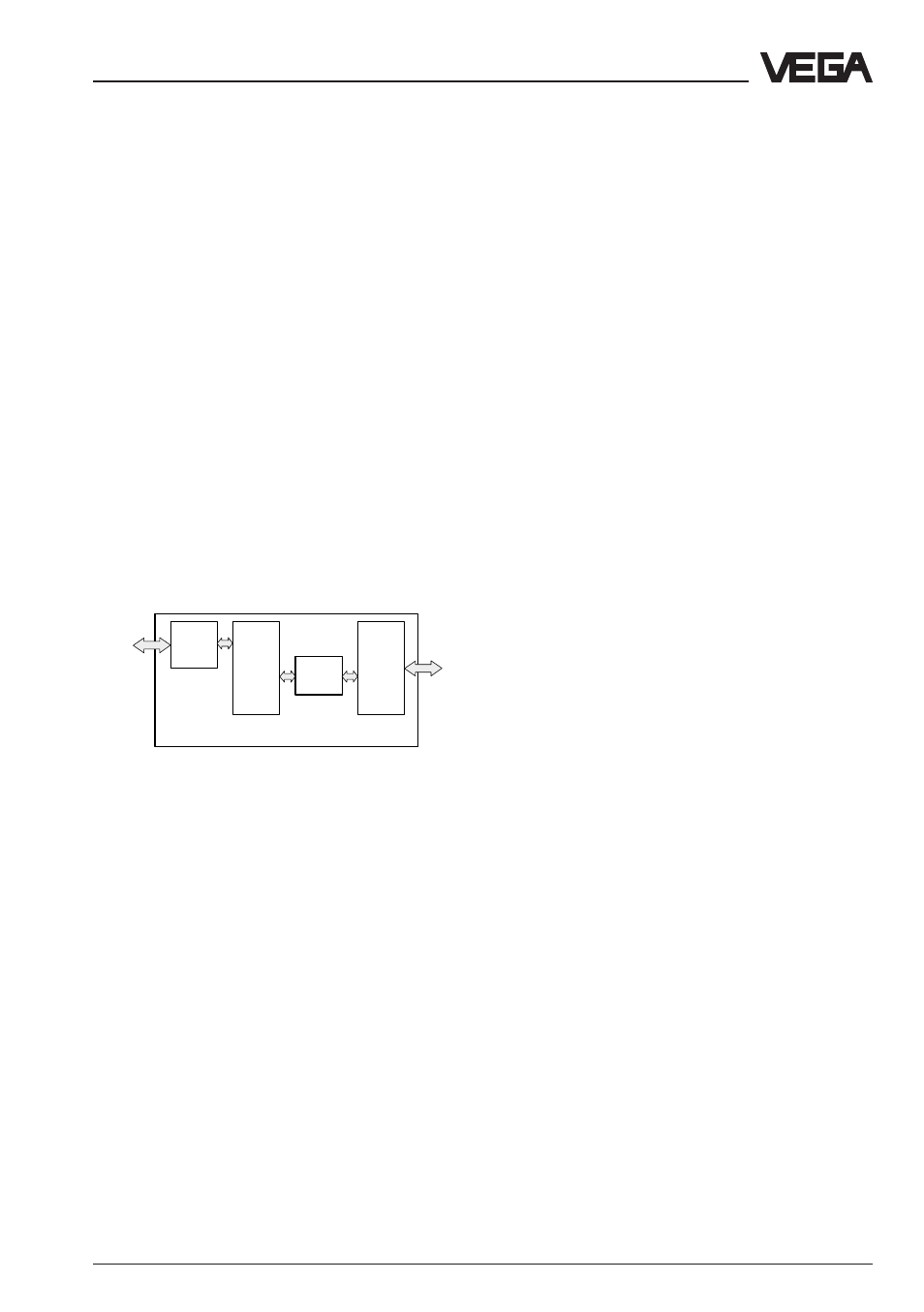

DISBUS

LOGBUS

Modbus

Function VEGACOM 557

Buffer

memory

Proc-

ess

image

Emis-

sion

memory

Test

conver-

sion

Product description

VEGACOM 557 on Modbus

The data communication between VEGACOM

557 and Modbus master is only carried out if

initiated by the master, which can enquire the

requested information by means of special

commands.

The data from DISBUS/LOGBUS are first

written in a buffer memory of VEGACOM 557.

The data set is transferred from this buffer

memory into a process image. The protocol

conversion software enquires the stored data

cyclically from the individual storage areas.

The data sets are checked and converted

into the Modbus data format. After the con-

version, the data are transferred into the

emission memory and are sent from there to

the Modbus. The Modbus transmits the data

to the DP-Master.

VEGACOM 557 with VVO or VV

Direct connection

As an alternative to the Modbus communica-

tion, a PC can be connected via the PC inter-

face (SUB-D-plug in the front panel of

VEGACOM 557). By means of the adjustment

and indicating software VEGA Visual Opera-

ting (VVO), the parameter adjustment can be

made on the signal conditioning instruments

connected to VEGACOM 557. The VEGA

adjustment concept includes the user-friendly

configuration and parameter adjustment of

the measuring system or the sensor with the

following instruments:

- VEGAMET series 500/600 signal condi-

tioning instruments

- VEGALOG 571 processing system

- VBUS ultrasonic/radar sensors.

The adjustment is menu-driven and window

oriented. No matter if a radar sensor, several

connected signal conditioning instruments or

a VEGALOG should be adjusted via the PC,

the procedure is always the same. As an-

other possibility, measured values and fault

signals of the entire processing facility can

be recorded and shown graphically by

means of the visualisation software VISUAL

VEGA (VV). Tools for processing and analy-

sis of history data are also available.

The configuration of the measurement loop

comprises, depending on the connected

instruments, e.g. the determination of output

functions or the configuration of individual

outputs or inputs. The user-orientated editing

of measurement loops is supported by

graphic means, such as e.g. vessel draw-

ings and pictographs that adapt to the se-

lected general conditions and options.

Thanks to graphic support, more complex

parameter adjustments such as e.g., the

input of a linearisation curve by means of

index markers, can also be done with ease.

Connection via modem

The PC interface supports, beside the direct

connection of a PC, also the operation via

modems. With this additional function, remote

parameter adjustment or remote diagnostics

of VEGA systems via VVO are possible.

Together with the visualisation software Visual

VEGA, even remote visualisations can be

carried out.