Measuring, Closing down, Maintenance – M&C TechGroup PMA 20 Operator's manual User Manual

Page 21: Trouble shooting

21

Gas sampling and gas conditioning technology

9-3.5.1-ME

17

MEASURING

For the first starting up at a new location, all steps in chapter 16 and 17 have to be performed.

By the requirements of precision the interval of the new calibration can be carried out daily or

weekly.

C A U T I O N !

The sample gas must be free from all liquid or solid particles, i.e. the dew

point of the gas has to be below the equipment temperature so that no

condensate will occur inside the equipment. If necessary, lower the dew

point by means of a cooler or dryer. For dust filtration use a filter of 2

micron porosity !

We will be pleased to inform you about an optimal gas conditioning

The analyser now is ready for operation.

18

CLOSING DOWN

In case of a short time closing down of the the analyser no further precautions are required.

In case of a closing down of the analyser for a longer period, it is recommended to flush the ana-

lyser with dry and clean inert gas (eg. surrounding air) in order to prevent a damage of the me a-

suring cell by aggressive and corrosive liquid gases.

19

MAINTENANCE

The analyser, woking with a physical measuring principle, requires no intensive and complex

maintenance. But the preceding components necessary for the sample gas conditioning are to be

maintained with special attention according to the respective operating manuals.

The calibration of zero and span is to be effected with the corresponding test gases according to

stability of the operating conditions and to the demands on the accuracy . Recommended interval

of calibration for standard applications: 1 x per week.

20

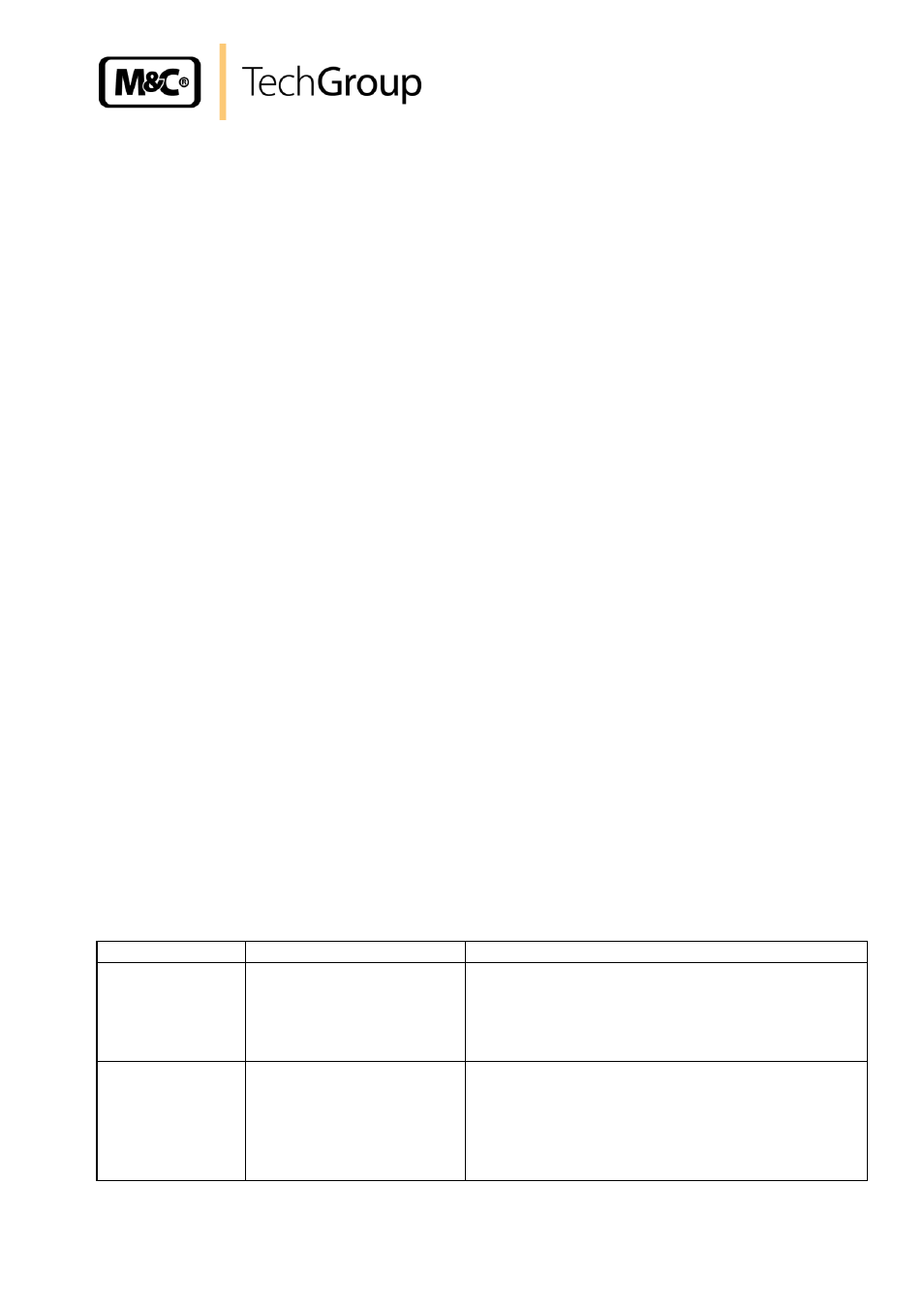

TROUBLE SHOOTING

Error

Possible reason

Check/Repair

No indication

No supply voltage

Check supply voltage according to type plate.

Check wether mains cable is plugged in accu-

rate.

Check fine fuse in the low heat device socket.

No sample gas

flow

Sample line or filter is

blocked

Contamination of the in-

ternal diaphragm pump

Check sample system.