Description, Figure 1, Flow characteristcs – M&C TechGroup FT-...-H2 Operator's manual User Manual

Page 9: 8description

9

Gas sampling and gas conditioning technology

5-2.1.1-ME

8

DESCRIPTION

The universal-filter out of PTFE with integrated filter elements (fineness 3 or 0,1 µm) is placed in an

electrically heated 2-part aluminium construction.

The temperature is controlled by an integrated compact capillary sensor thermostat with an excess

temperature limit switch with reset key at +30°C above T

set

and an alarm function for low temperature

alarm at -30°C below T

set

with voltage free status-alarm contact. The thermostat as well as the

electrical terminals are placed in the junction box.

The temperature of the filter is shown on a thermometer. For isolation and protection reasons, the

heated filter part is covered with a cap.

To prevent heating-interruptions, the in- and outlet connection area is heated too. The clamps are

fixed in order to support the sample lines.

The filter in- and outlet can be turned 180° on the oven top position to achieve easy mounting and

flexible adaptation to local circumstances.

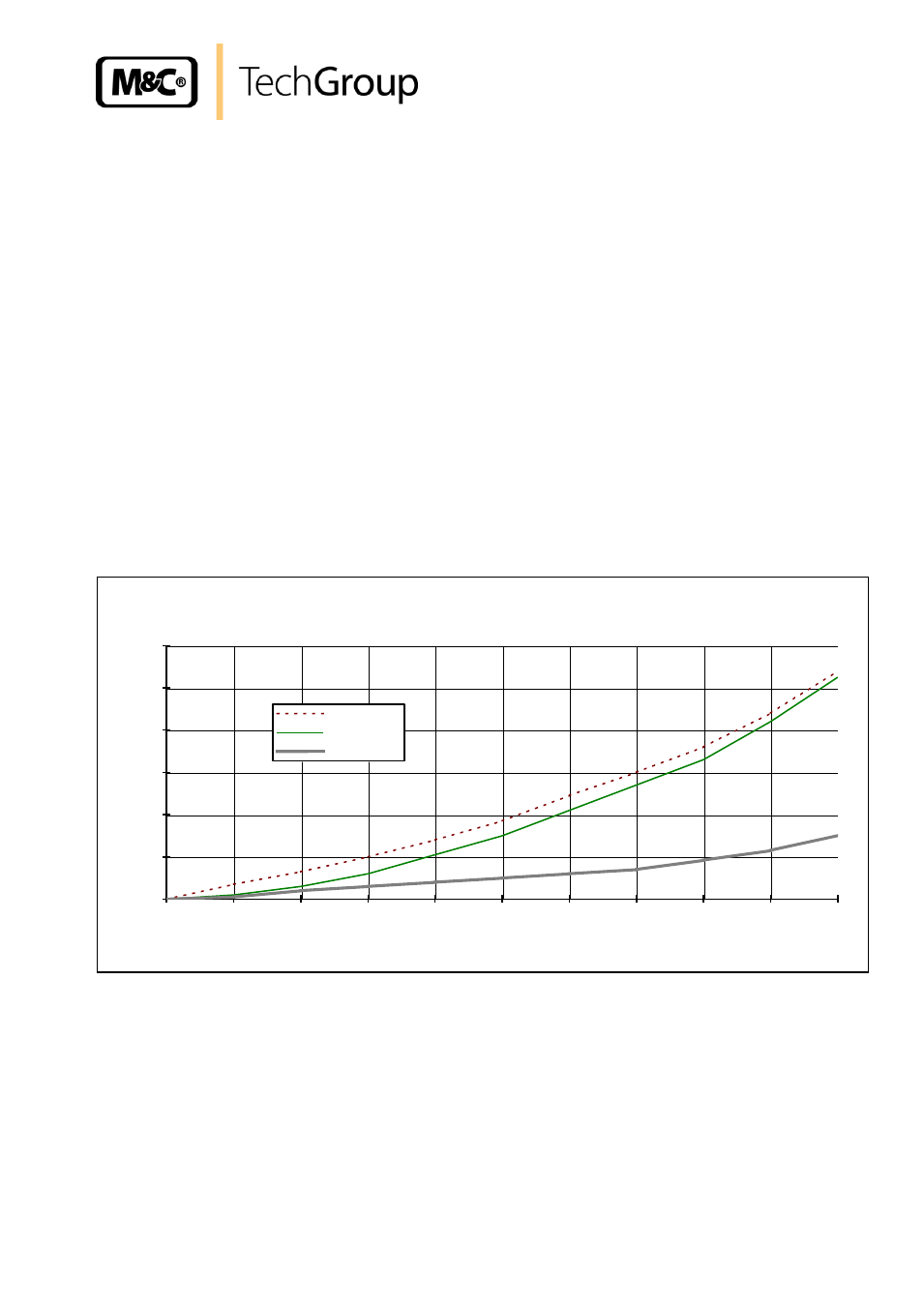

The following diagram illustrates the differential pressures of the different filter element materials in

dependance on the gas flow.

differential pressure in mbar with clean filter elements

0

10

20

30

40

50

60

0

50

100

150

200

250

300

350

400

450

500

air flow in l/hr at 20°C

d

if

fe

re

n

ti

a

l

p

re

s

s

u

re

m

b

a

r

FT-3SS-H2

FT-3G-H2

FT-0,1GF-H2

Figure 1

Flow characteristcs