M&C TechGroup EC-EX Operator's manual User Manual

Page 21

21

Gas sampling and gas conditioning technology

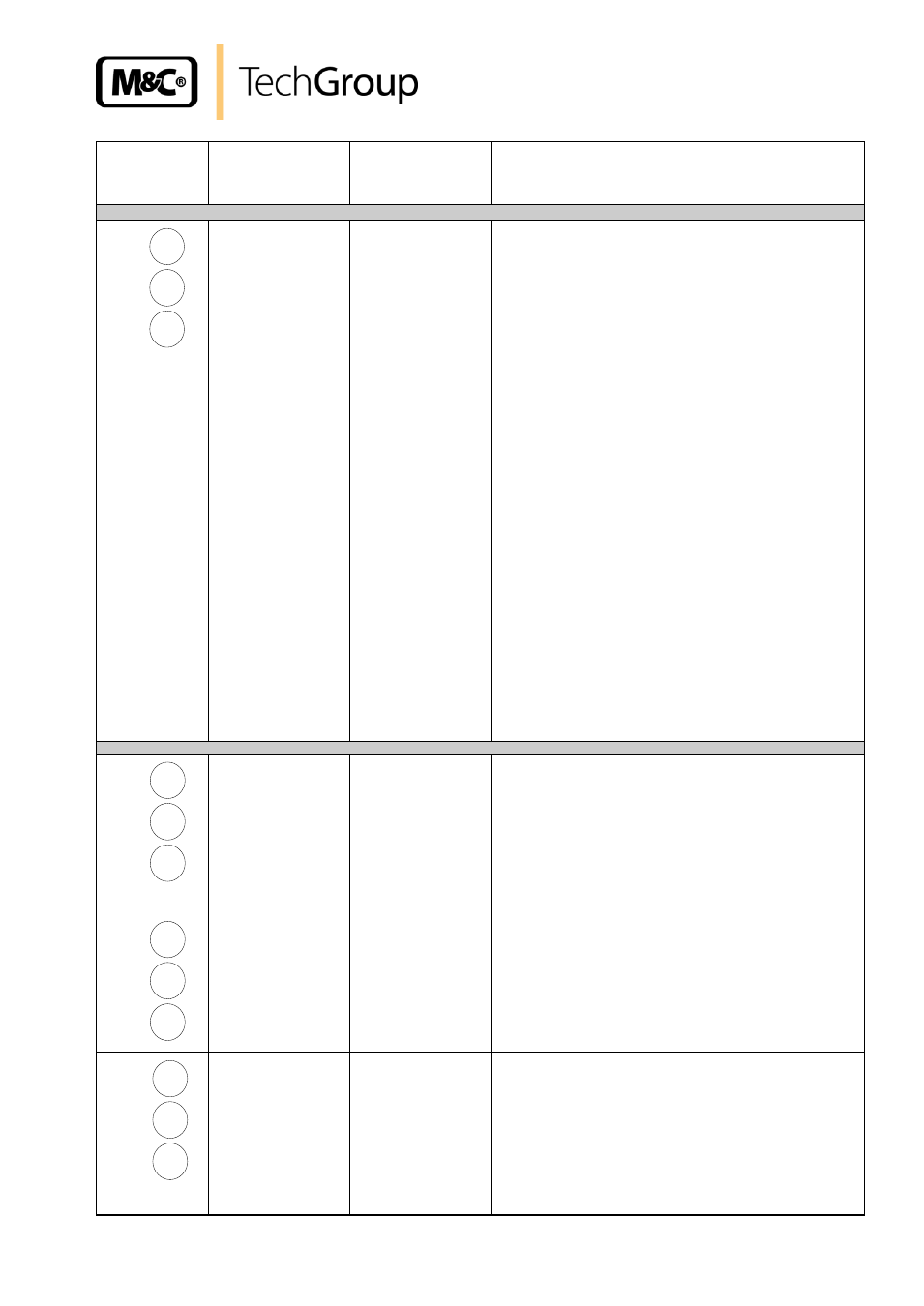

3-4.1ME EC-EX 9904

LED display Function error

and status

alarm

Probable cause

Checking / Correction

°C >

ON

°C <

red

pink

(red LED V18

on control

board is on)

Equipment does

not cool or

cooling is

insufficient;

see above

Cooling

compressor is

not running;

Cooling

compressor is

running; Cooler

is overstressed

1. Check voltage in the EEx-d box at terminals

X2.9 and X2.6 (N) (drive of the compressor

starting coil). In case of 230V (115V) renew the

EC-EX control board.

There is no voltage at terminals X2.9 and X2.6

(N):

2. Check the starting coil;

The red LED V18 must be light up. Check the

voltage at clamps X2.12 and X2.6. In case of

voltage change the control board or renew the

capacitors.

Note: If the compressor is stuck the described

stage (red LED V18 on) can alternate with the

above described stage (red LED V18 out),

because the protective motor switch will release

and switch on again after 3 min.

Check:

-Is gas flow 4 x 250 l/h maximum?

-Is ambient temp. +45°C maximum?

-Cooling fins are dirty?

Release EC-EX temperature sensor R51

at terminals X3.1+ X3.2 and measure

resistance.

It should be > 1.7 k

at 20°C ambient temp.

If O.K.:

Replace complete EC-EX compressor unit

°C >

ON

°C <

green

red

or

°C >

ON

°C <

green

red

Equipment does

not cool;

Cooling

compressor

stopped;

Release EC-EX temperature sensor R51 at

X3.1 and X3.2 and measure resistance.

It should be >1.7 k

at 20°C ambient temp.

If faulty:

fit new EC-EX temperature sensor to cooling

block using heat sink paste.

If o.k.:

Replace faulty EC-EX control board.

°C >

ON

°C <

red

pink

Cooler has been

over-cooled

(temp. < 2°C);

Cooling

compressor runs

to long or

continuously;

Release EC-EX temperature sensor R51 at

X3.1 and X3.2 and measure resistance.

Should be >1.7 k

at 20°C ambient temp.

If faulty:

fit new EC-EX temperature sensor to cooling

block using heat sink paste.

If o.k.:

Replace faulty EC-EX control board