Description, Function, Figure 2 – M&C TechGroup ECM Series Operator's manual User Manual

Page 9: Ecm-2g, 9description, 10 function

9

Gas sampling and gas conditioning technology

3-3.0-ME

9

DESCRIPTION

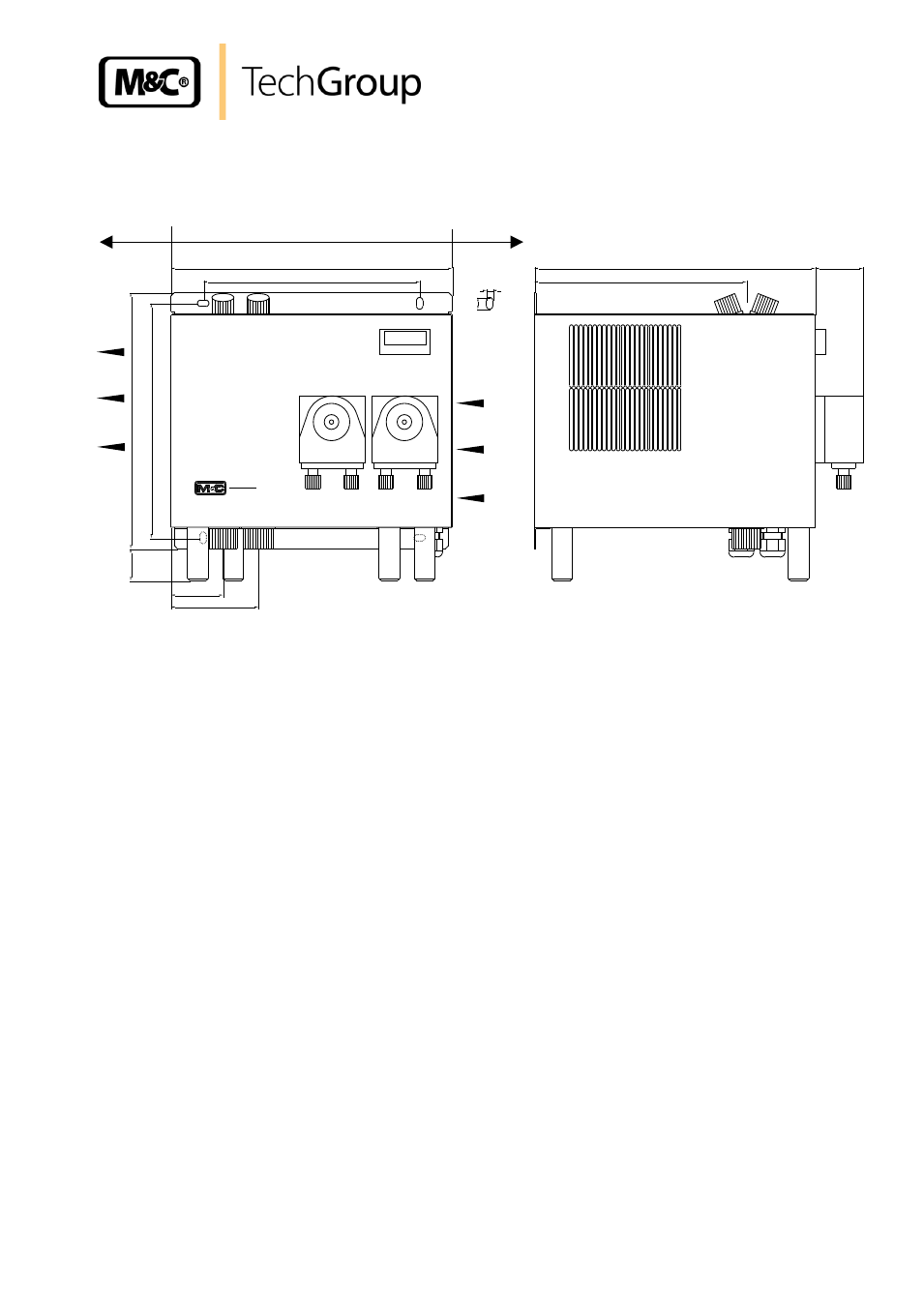

Figure 2 shows the ECM-2G cooler unit

.

Min. side distance

100

100

EC

M

Cooler

220

240

30

208

270

204

270

46

11

6

84

50

ventilation

opening

Compressor

ventilation outlet

Dimensions in mm

Figure 2 ECM-2G

The cooler ECM is equally suitable for wall installation. The depth of the housing of the cooler is

270mm (316mm with optional mounted peristaltic pumps ).

On the upper side of the cooler casing you will see the cutouts for 1 or 2 heat exchangers. Sample gas

enters and leaves the heat exchangers by the correspondingly connections on the upper part of the

heat exchangers (see 8. technical data).

The main power connector and the contact output for the status alarm can be connected at terminals

X1 respectively X3 located behind the removable front panel of the ECM housing.

At the bottom of the housing the following connections are provided as standard:

standard condensate outlets from the heat exchangers,

cable bushings 2 x M20 x 1,5 clamp range 6-12mm;

With under- respectively ambient pressure the condensate removal happens via the peristaltic pumps

SR25.2 optionally implemented in the cooler housing or externally with collecting vessels type

TG.../TK... . With over-pressure an automatic liquid drainer type AD-... is suitable.

10

FUNCTION

The M&C gas cooler type ECM is a compressor cooler with status alarm capability. This ensures

100% availability of the cooler.