Reception and storage, Figure 3, Schematic diagram of the heat exchanger function – M&C TechGroup ECM Series Operator's manual User Manual

Page 10

10

Gas sampling and gas conditioning technology

3-3.0-ME

Up to 2 Jet-stream heat exchangers made of Borosilicate glass, PVDF or stainless steel are located in

a heat-insulated cooling block. All the heat exchangers are easily accessible and are arranged in such

a way that they can be removed very simply.

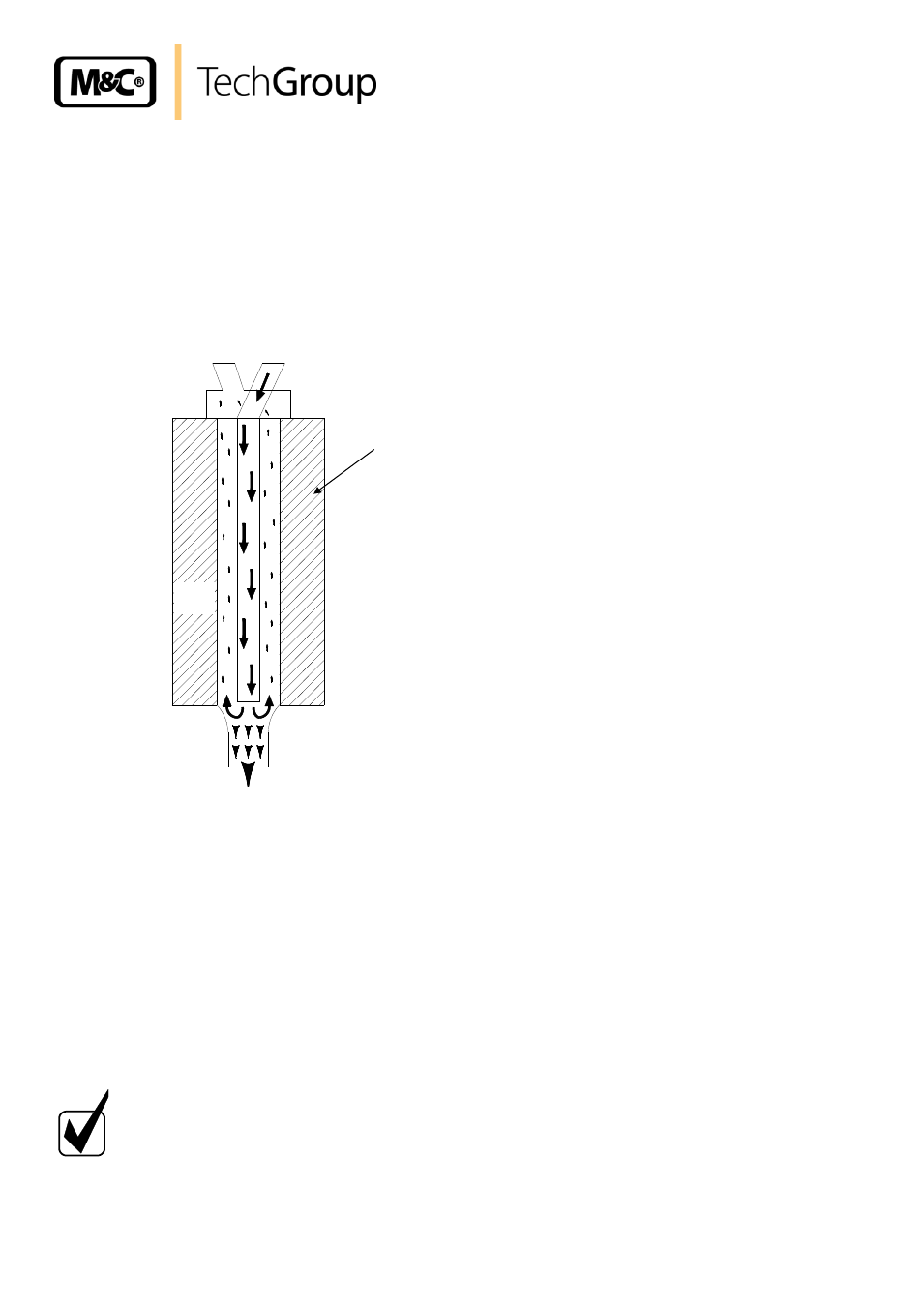

Figure 3 shows a schematic diagram of the functioning of the heat exchanger: The compressor cooler

system has a heat-insulated cooling block at a constant temperature of +5°C. The novel construction

of the heat exchanger guarantees a very good pre-separation of condensate and for that reason an

optimal drying of sample gas.

+5°C

Sample

OUT

Sample

IN

Condensate OUT

Cooling

block

Figure 3 Schematic diagram of the heat exchanger function

11

RECEPTION AND STORAGE

The ECM gas cooler is a complete pre-installed unit.

Carefully inspect the ECM and any special accessories included with it immediately on arrival

by removing them from the packing and checking for missing articles against the packing list !

Check the items for any damage in transit and, if required, inform the shipping insurance

company immediately of the damage found!

N O T E !

The cooler must be stored in a weather protected frost-free area!

During transport and when in storage, the cooler must always be stood up

with the transport feet positioned underneath so that the oil in the closed

compressor circuit cannot run out of this compressor case.

If the cooler is transported on its back by mistake, it must stood in the

operating position for approx. 24 hours before it is switched on!