Change of contact pulleys and springs, Figure 6, Change of the pump tube – M&C TechGroup ECM Series Operator's manual User Manual

Page 17

17

Gas sampling and gas conditioning technology

3-3.0-ME

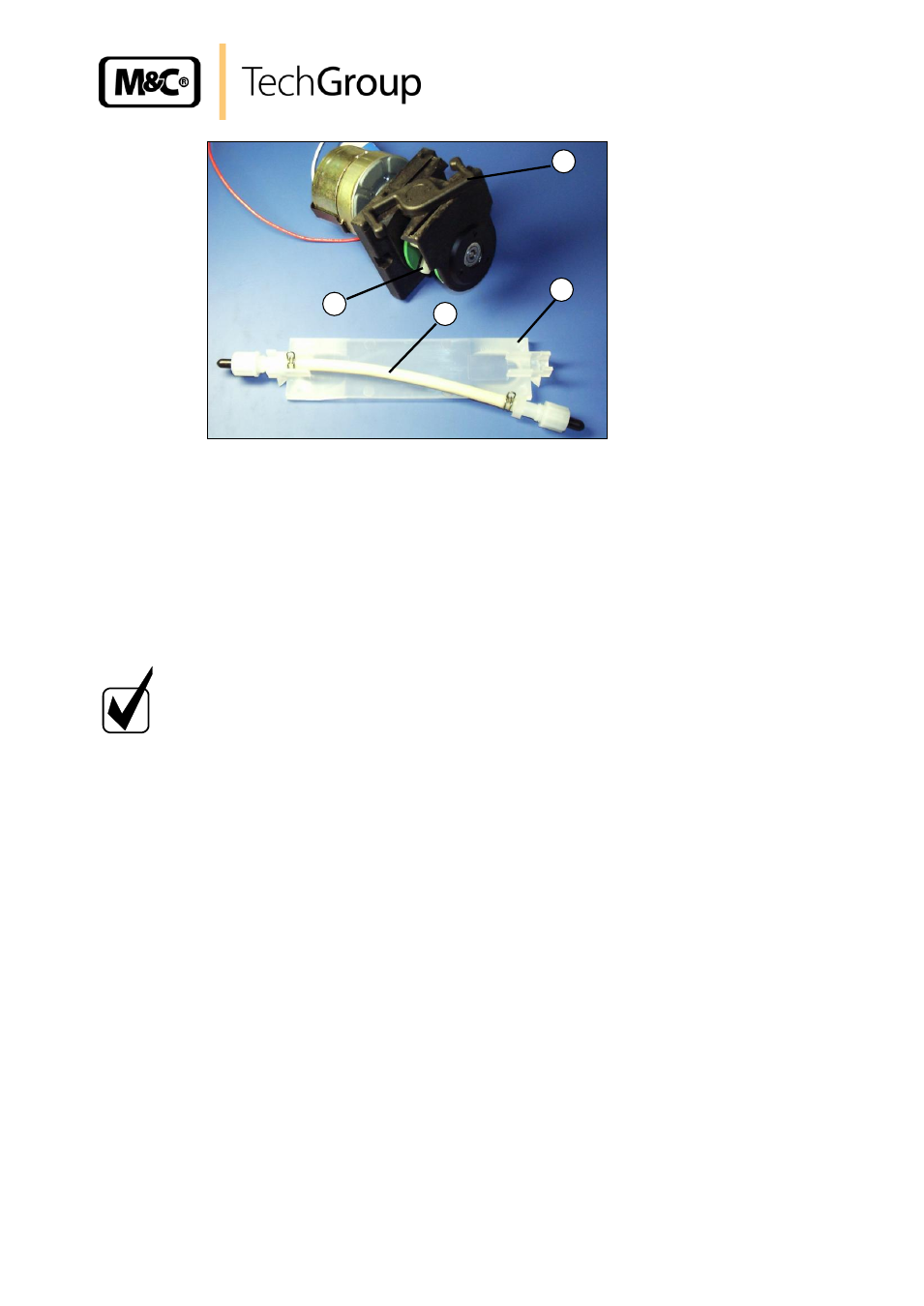

1

2

3

4

Figure 6 Change of the pump tube

Take off the cooler of the mains;

Open hose connectors at the pump;

Press conveying belt

at the recessed grips and turn Sbolt 2 clockwise up to limit stop;

Take away conveying belt

and remove the old hose set

from the guides by the hose

connectors;

Press the two contact pulleys

and check whether the spring pressure is still sufficient, if not,

the contact springs have to be changed;

Put the new hose set

with the hose connectors into the guides of the conveying belt

;

N O T E !

Only the usage of the original hose set guarantees a perfect function.

Never lubricate the hose.

Before mounting the pump check all parts for impurity and clean if

necessary.

Put the conveying belt

with the new hose

into the dovetail guide of the pump body;

Press conveying belt at the recessed grips and simultaneously turn the S-bolt

anticlockwise

until it snaps;

Switch on pump.

16.3.2 CHANGE OF CONTACT PULLEYS AND SPRINGS

Take off the cooler of the mains;

Unscrew the nut of the pump head (span of the jaw 5,5);

Draw the pump head out of the motor shaft;

Now the driver can picked out of the pump head and is ready for maintenance.

The removal of the springs (4 pcs.) away from the driver is possible without the aid of any

tools. Therefore press together the spring and take it out of the groove in the driver respectively

out of the boring in the axle. Now the roller bearing axle can be dismounted and the contact

pullets are ready for change.

Remounting happens in the opposite way.