Measuring – M&C TechGroup PMA 10S Operator's manual User Manual

Page 23

23

Gas sampling and gas conditioning technology

9-1.1-ME

N O T E !

Always calibrate at the flow rate that is adjusted for the measurement

too.

Wait approximately 20

– 30 sec. until the indication has stabilised.

If necessary adjust span accurately according to the check gas concentration with a screw

driver at the span potentiometer in the front panel. In case of air e.g. to 20,9 % O

2

.

Check output signals at 20,9% O

2

:

Shut off pressure reducer valve and bottle- resp. Instrument air valve resp. integrated

sample gas pump.

Disconnect hose connection at the analyser.

Determination of the output signal:

(S

e

– S

np

) V resp. mA x gas concentration Vol % O

2

upper range value Vol % O

2

Se = Final value, signal output

Snp = Zero, signal output

Shut off pressure reducer output valve and bottle valve. Druckreglerausgangsventil und

Flaschenventil schließen. Disconnect hose connection at the analyser.

The span calibration is finished.

N O T E !

If during the span calibration great variations have to be co mpensated

(>2% O

2

) at the potentiometers, a second zero and span calibration is

reasonable.

18

MEASURING

For the first starting up at a new location, all steps in chapter 16 and 17 have to be performed.

By the requirements of precision the interval of the new calibration can be carried out daily or

weekly.

C A U T I O N !

The sample gas must be free from all liquid or solid particles, i.e. the dew

point of the gas must be below the equipment temperature so that no

condensate will occur inside the equipment. If necessary, lower the dew

point by means of a cooler or dryer. For dust filtration use a filter of 2

micron porosity !

We will be pleased to inform you about an optimal gas conditioning

The analyser now is ready for operation.

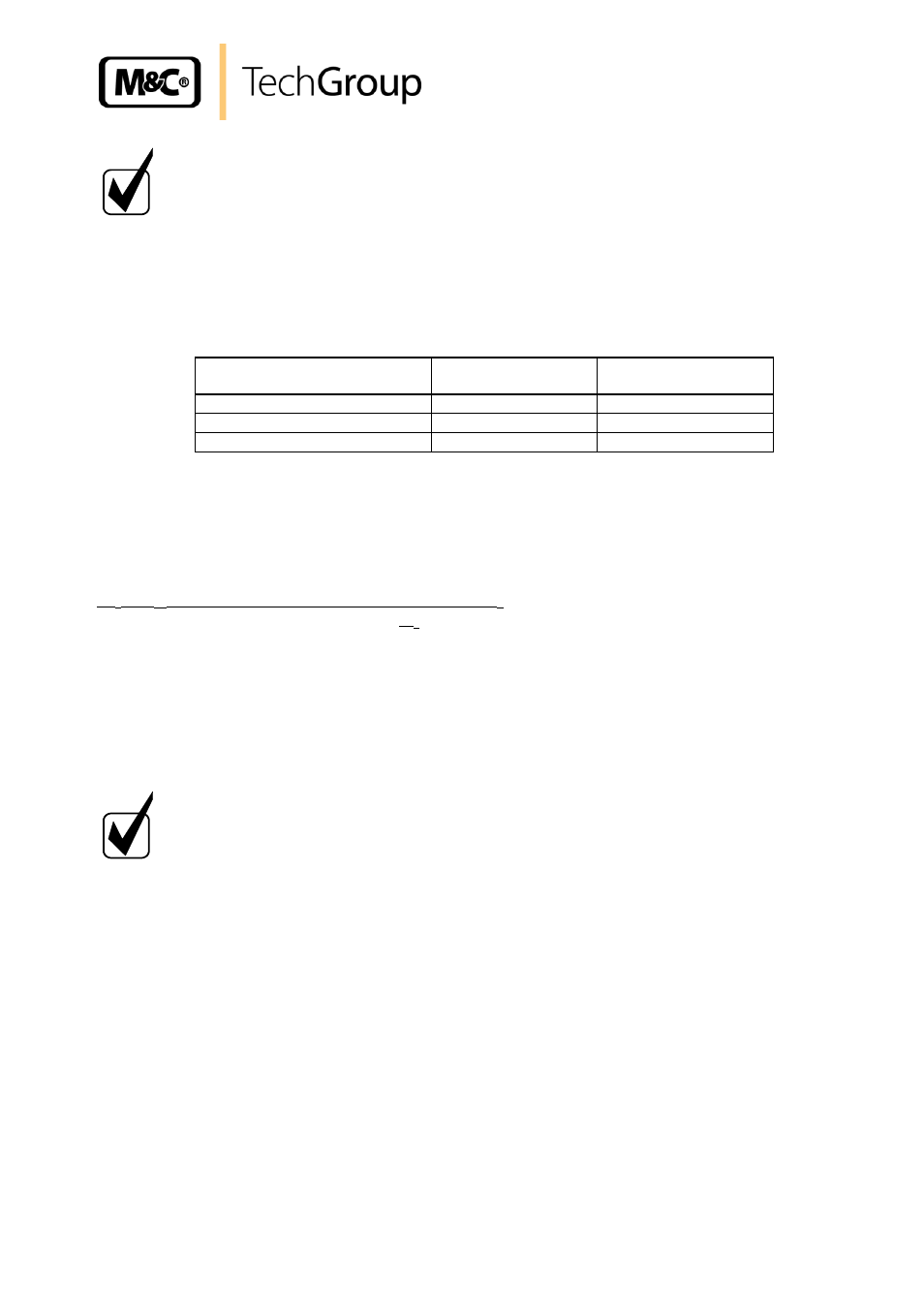

Output signal

Measurement

range 100 % O

2

Measurement

range 30 % O

2

0-1 V

0,209 V

0,697 V

0-20 mA

4,18 mA

13,93 mA

4-20 mA

7,34 mA

15,15 mA

+ S

np