Description, Figure 1, Dimensions – M&C TechGroup PMA 10S Operator's manual User Manual

Page 10

10

Gas sampling and gas conditioning technology

9-1.1-ME

9

DESCRIPTION

The PMA 10 is a reliable and easy-to-operate instrument and immediately operable. The light-

weight instrument is built into a portable housing. The four measuring ranges are displayed on

the analogue meter with 30% and 100% scale and the 100% O

2

range also on the digital meter.

One output signal 0-1V is available as standard. Sample gas connections as well as a connector

for the output signal are located on the front panel of the analyser. The connectors for incoming

power supply and optional O

2

alarm contact are located at the rear panel. The sample gas enters

the analyser via an internal protective fine-filter. The required flow rate can be adjusted at the

flowmeter with a needle valve, mounted on the front panel upstream the M&C measuring cell.

Options: mA-output signal, O

2

alarm, rechargeable battery, internal pump and TÜV certificate.

The PMA 10S oxygen purity analyser, being an extended version of the PMA 10, is provided with

an electronic suppression system which enables oxygen purity measureents within the expanded

99-100 vol.% range. This measuring range is displayed on the analogue meter whilst the digital

indicator remains for the 0-100% reading. The electronic zero suppression system may be se-

lected by means of a push button switch which is located on the control panel of the instrument.

The PMA 10S analyser can normally be used also for its standard PMA10 functions. Oxygen

purity measurements could only be made discontinuously. The measuring accuracy of the ana-

lyser can be maintained when calibration of the instrument with a certified gas takes place before

the measurement procedure in order to avoid influence of ambient temperature and pressure. A

measurement of 1 vol.% can be easily realized whilst the maximum value remains at 100 vol.%.

Other measurement within this range can be performed.

The physical measuring principle is based on the magneto -dynamic oxygen measuring cell and is

one of the most accurate methods for oxygen determination within the range of 0 - 100 Vol.% O

2

.

The measuring cell has a low volume of only 2 ml, is very robust, has an extremely low drift and

a very fast response time. The 90%-time is approximately 3 sec. and is achieved by a gas flow

rate of 60 Nl/hr through the measuring cell. The change of the flow in the range of 0

– 60 Nl/hr air

causes a change of the O

2

indication of < 0,1 vol. % O

2

.

An internal power supply unit provides the analyser with the necessary supply voltage. At the rear

side there is the low heat device socket.

N O T E !

The analyser is not thermostated and should be operated only in

areas with constant ambient temperature. If this is not possible, the

analyser has to be calibrated before every measurement, to guaran-

tee the accuracy of measurement.

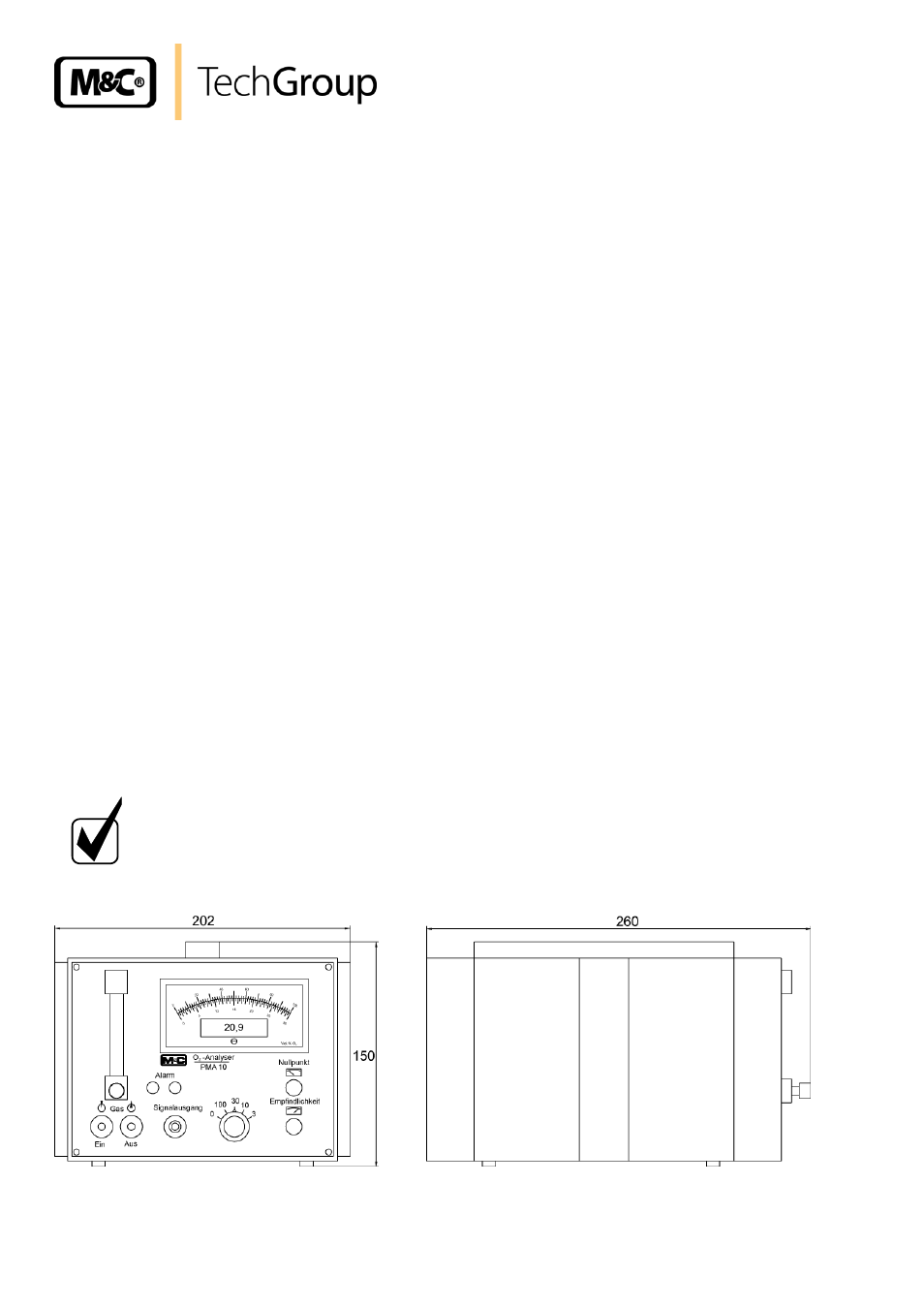

Figure 1

Dimensions