Lubrication, Cleaning procedures, Clean the exterior – Zebra Technologies Z4Mplus User Manual

Page 110: Lubrication cleaning procedures

Routine Maintenance

Lubrication

102

13163L-001 Rev. A

Z4Mplus/Z6Mplus User Guide

1/18/06

Lubrication

No lubrication is needed for this printer.

Cleaning Procedures

Specific cleaning procedures are provided on the following pages.

recommended cleaning schedule.

.

Clean the Exterior

You may clean the exterior surfaces of the printer with a lint-free cloth and a small amount of a

mild detergent, if necessary. Do not use harsh or abrasive cleaning agents or solvents.

Caution • Some commercially available lubricants will damage the finish and the

mechanical parts if used on this printer.

Important •

Zebra is not responsible for damage caused by the use of cleaning fluids on this

printer.

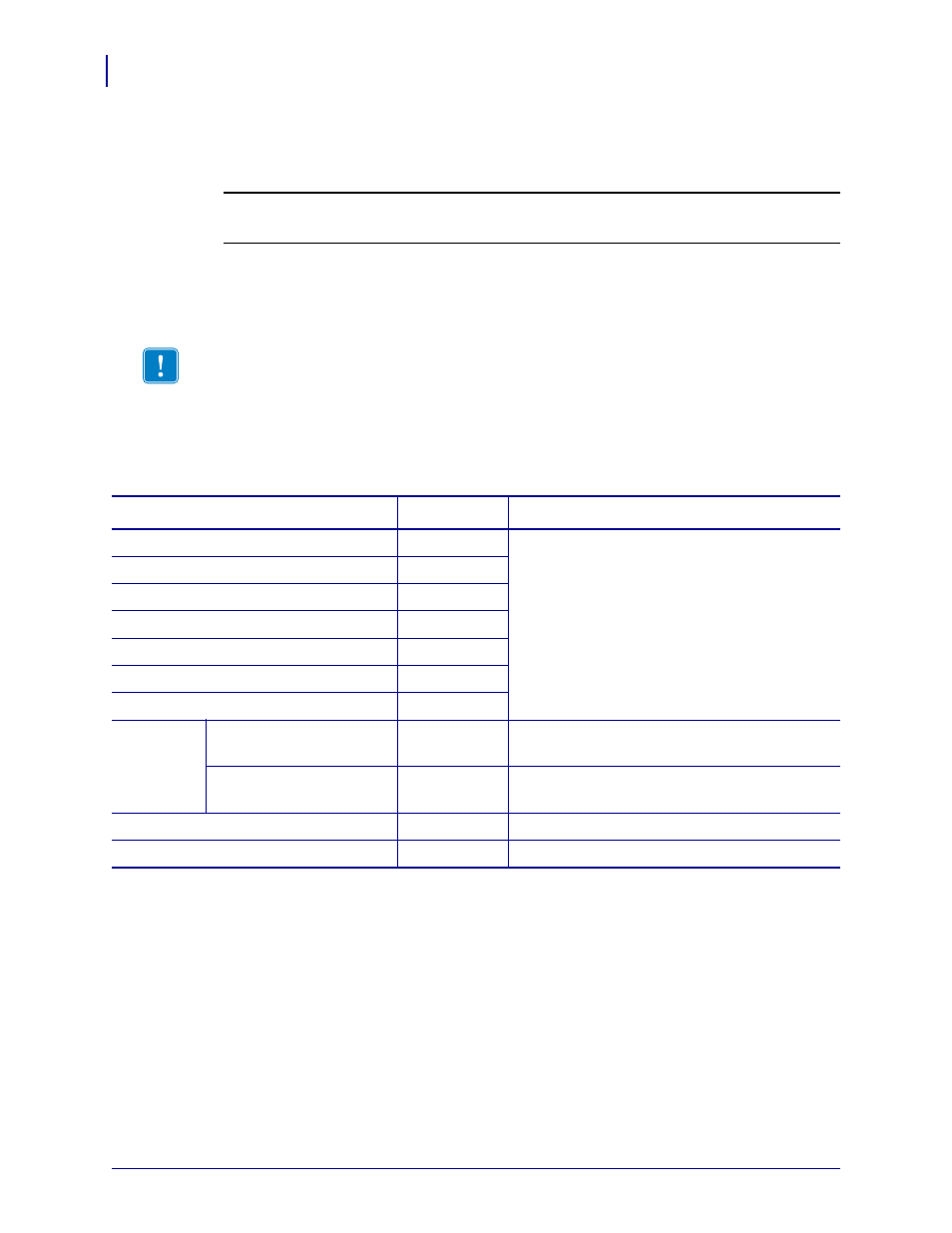

Table 11 • Recommended Cleaning Schedule

Area

Method

Interval

Printhead

Solvent*

Direct Thermal Mode: After every roll of

media (or 500 feet of fanfold media).

Thermal Transfer Mode: After every roll of

ribbon or three rolls of media.

These intervals are intended as guidelines only.

You may have to clean more often, depending

upon your application and media.

Platen roller

Solvent*

Media sensors

Air blow

Ribbon sensor

Air blow

Media path

Solvent*

Ribbon path

Solvent*

Pinch roller. (part of Peel-Off option)

Solvent*

Cutter

module

If cutting continuous,

pressure-sensitive media

Solvent*

After every roll of media (or more often,

depending upon your application and media).

If cutting tag stock or label

liner material

Solvent* and

air blow

After every two or three rolls of media.

Tear-off/peel-off bar

Solvent*

Once a month.

Take-label sensor

Air blow

Once every six months.

* Zebra recommends using Preventive Maintenance Kit (part number 47362) or a solution of 90% Isopropyl and

10% deionized water)