Parker Hannifin SERVO CONTROLLER OEM6250 User Manual

Page 51

Appendix A – Tuning

4 5

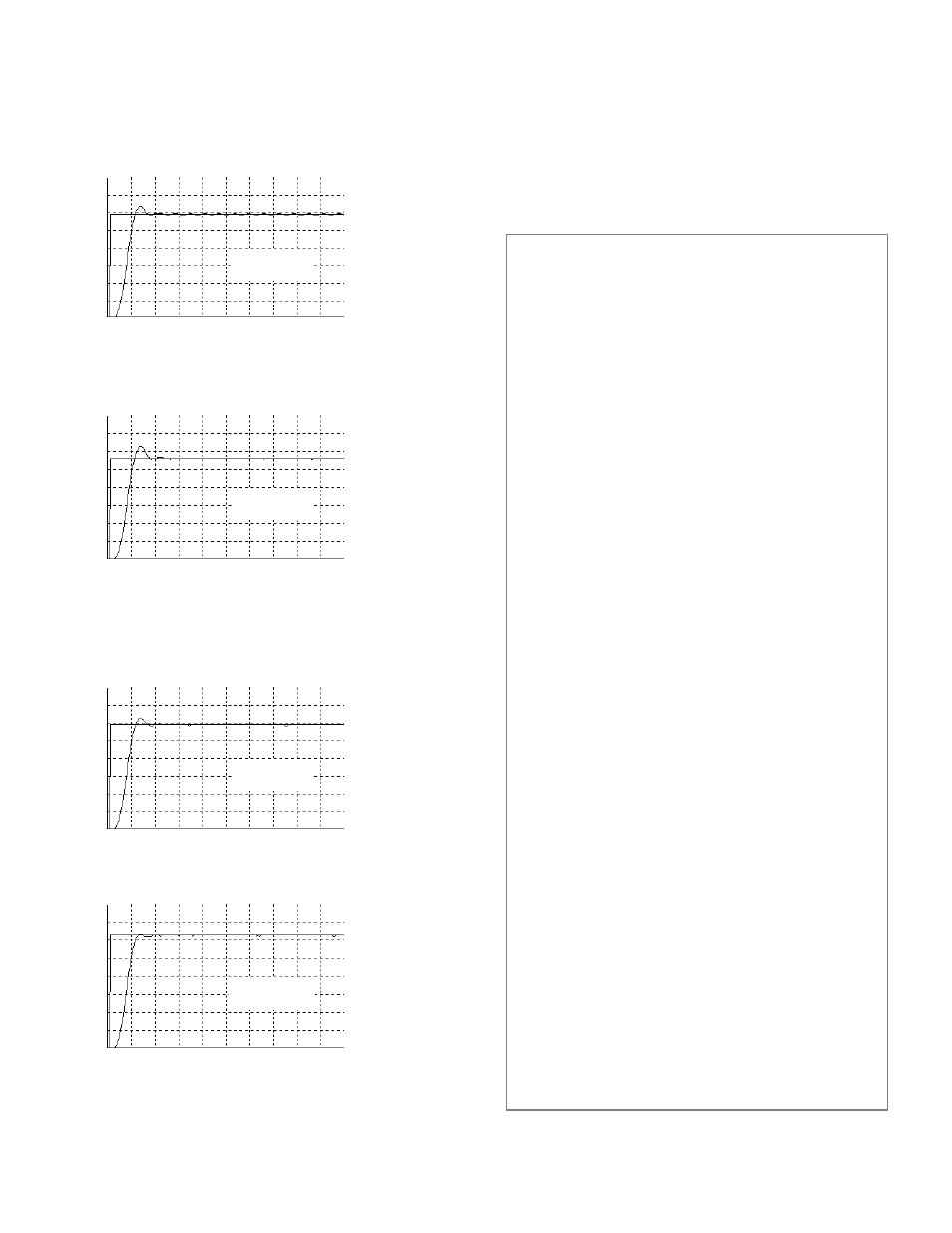

Step 8

After raising the SGV gain to 2.4, overshoot is reduced a

little, but chattering reappears. This means the gains are

still too high.

Next, we should lower the SGV gain until chattering stops.

SGP = 85

SGV = 2.4

Step 9

After lowering the SGV gain to 2.2 (even less than in the 2.3

setting in Step 7), chattering stops.

Next we should lower the SGP gain.

SGP = 85

SGV = 2.2

Step 10

Overshoot is reduced very little after lowering the SGP gain

to 70. (The SGV gain might have been lowered too much in

Step 9.)

Next, we should try raising the SGV gain again until the

overshoot is gone.

SGP = 70

SGV = 2.2

Step 11

When we raised the SGV gain to 2.52, the step response

became fast and very stable.

SGP = 70

SGV = 2.52

Step 12

Now that we have determined the appropriate SGP and SGV

gains, we can include them in the OEM6250’s setup

program. We put the gains in the setup program because we

want the OEM6250 to power up in a “ready state” for

motion. For more information on creating a setup program,

refer to the 6000 Series Programmer’s Guide.

Example Setup Program:

DEF SETUP

; Begin def. of "setup" program

DRIVE¯¯

; Disable both drives

INDAX2

; Place both axes in use

SSFR4

; Servo sampling frequency ratio

DRFLVL11

; Set drive fault level to

; "active high" for both axes

KDRIVE11

; Enable DISABLE ON KILL feature

; *********************************************

; * Setup for encoders (will need to switch *

: * between encoder and ANI feedback) *

; *********************************************

SFB1,1

; Select encoder feedback for

; both axes (subsequent scaling,

; gains, servo offset, PSET,

; and SMPER commands are specific

; to encoder feedback)

ERES4000,4000

; Set encoder resolution to

; 4,000 counts/rev

SCLA4000,4000

; Set scaling for programming

; accel/decel in revs/sec/sec

SCLV4000,4000

; Set scaling for programming

; velocity in revs/sec

SCLD4000,4000

; Set scaling for programming

; distances in revs

SGP70,70

; Set proportional feedback gain

SGV2.52,2.52

; Set velocity feedback gain

SMPER

.

001

,.

001 ; Set max. position error to

; 1

/

1000

of a

rev

(

4

encoder

counts

)

PSET0,0

; Set current position as

; absolute position zero

; *********************************************

; * Setup for ANI feedback (OEM6250-ANI ONLY) *

; *********************************************

SFB2,2

; Select ANI feedback for both

; axes (subsequent scaling,

; gains, servo offset, PSET,

; and SMPER parameters are

; specific to ANI feedback)

SCLA819,819

; Set scaling for programming

; accel/decel in volts/sec/sec

SCLV819,819

; Set scaling for programming

; velocity in volts/sec

SCLD819,819

; Set scaling for programming

; distances in volts

SGP1,1

; Set proportional feedback gain

SGI0,0

; Set integral feedback gain

SGV.5,.5

; Set velocity feedback gain

SMPER.01,.01

; Set max. position error to

; 1/100 of a volt (8 ANI counts)

PSET5,5

; Set current position as

; absolute position 5

SFB1,1

; Select encoder feedback for

; start of main program

; *********************************************

; * Insert other appropriate commands in the *

; * setup program (e.g., custom power-up mesg,*

; * scaling factors, input function assignmts,*

; * output function assignments, input and *

; * output active levels, etc.). See Prog. *

; * Guide, Chapter 3, for more information. *

; *********************************************

END

; End definition of "setup" prog

STARTP SETUP

; Assign the program named setup

; as the program to be executed

; on power up & reset