Alarms and alerts – Sterling AquaSnap 30RA010-055 User Manual

Page 53

53

Alarms and Alerts —

These are warnings of abnormal

or fault conditions, and may cause either one circuit or the

whole unit to shut down. They are assigned code numbers as

described in Table 29.

Automatic alarms will reset without operator intervention if

the condition corrects itself. The following method must be

used to reset manual alarms:

Before resetting any alarm, first determine the cause of the

alarm and correct it. Enter the Alarms mode indicated by the

LED on the side of the Scrolling Marquee Display. Press

and

until the sub-menu item RCRN “RESET

ALL CURRENT ALARMS” is displayed. Press

.

The control will prompt the user for a password, by displaying

PASS and WORD. Press

to display the default pass-

word, 1111. Press

for each character. If the password

has been changed, use the arrow keys to change each individu-

al character. Toggle the display to “YES” and press

.

The alarms will be reset.

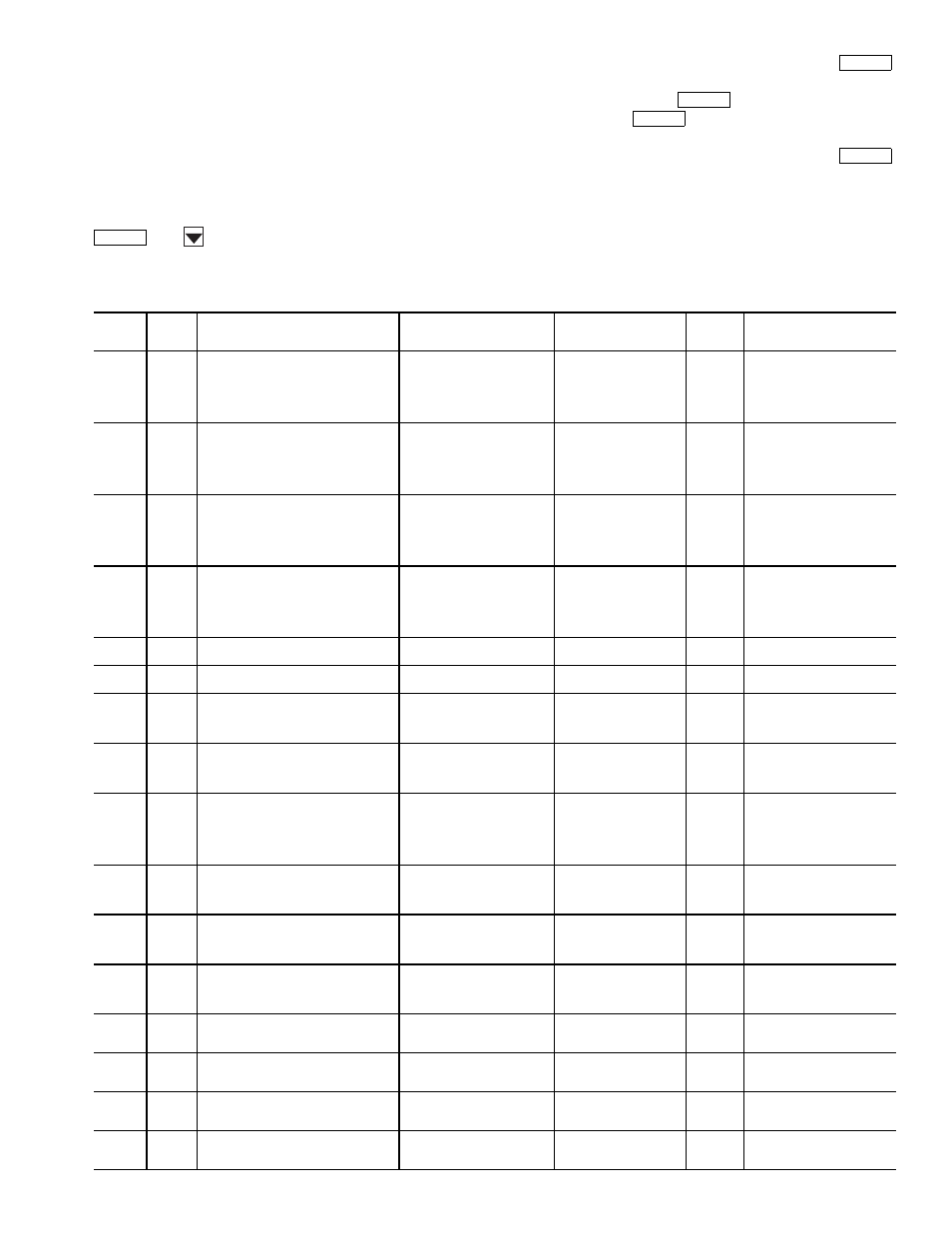

Table 29 — Alarm and Alert Codes

ENTER

ENTER

ENTER

ENTER

ENTER

ALARM/

ALERT

CODE

ALARM

OR

ALERT

DESCRIPTION

WHY WAS THIS

ALARM

GENERATED?

ACTION TAKEN

BY CONTROL

RESET

METHOD

PROBABLE

CAUSE

T051

Alert

Circuit A, Compressor 1

Failure

Compressor feedback signal

does not match relay state

Compressor A1 shut

down.

Manual

High-pressure switch open,

faulty auxiliary contacts, loss

of condenser air, liquid

valve closed, filter drier

plugged, non-condensables,

operation beyond capability.

T052

Alert

Circuit A, Compressor 2

Failure

Compressor feedback signal

does not match relay state

Compressor A2 shut

down.

Manual

High-pressure switch open,

faulty auxiliary contacts, loss

of condenser air, liquid

valve closed, filter drier

plugged, non-condensables,

operation beyond capability.

T055

Alert

Circuit B, Compressor 1

Failure

Compressor feedback signal

does not match relay state

Compressor B1 shut

down.

Manual

High-pressure switch open,

faulty auxiliary contacts, loss

of condenser air, liquid

valve closed, filter drier

plugged, non-condensables,

operation beyond capability.

T056

Alert

Circuit B, Compressor 2

Failure

Compressor feedback signal

does not match relay state

Compressor B2 shut

down.

Manual

High-pressure switch open,

faulty auxiliary contacts, loss

of condenser air, liquid

valve closed, filter drier

plugged, non-condensables,

operation beyond capability.

A060

Alarm

Cooler Leaving Fluid

Thermistor Failure (T1)

Thermistor outside range of

–40 to 245 F (–40 to 118 C)

Chiller shutdown

immediately

Automatic Thermistor failure, damaged

cable/wire or wiring error.

A061

Alarm

Cooler Entering Fluid

Thermistor Failure (T2)

Thermistor outside range of

–40 to 245 F (–40 to 118 C)

Chiller shutdown

immediately

Automatic Thermistor failure, damaged

cable/wire or wiring error.

T068

None

Circuit A Return Gas Thermistor Failure

If return gas sensors are

enabled (RG.EN) and

thermistor is outside range of

–40 to 245 F (–40 to 118 C)

None

Automatic Thermistor failure, damaged

cable/wire or wiring error.

T069

None

Circuit B Return Gas Thermistor Failure

If return gas sensors are

enabled (RG.EN) and

thermistor is outside range of

–40 to 245 F –40 to 118 C)

None

Automatic Thermistor failure, damaged

cable/wire or wiring error.

T073

Alert

Outside Air Thermistor

Failure (T9)

Thermistor outside range of

–40 to 245 F (–40 to 118 C)

Temperature reset

disabled. Chiller runs

under normal control/set

points. When capacity

reaches 0, cooler/pump

heaters are energized.

Automatic Thermistor failure, damaged

cable/wire or wiring error.

T074

Alert

Space Temperature

Thermistor Failure (T10)

Thermistor outside range of

–40 to 245 F (–40 to 118 C)

Temperature reset

disabled. Chiller runs

under normal control/set

points.

Automatic Thermistor failure, damaged

cable/wire or wiring error.

T077

Alert

Circuit A Saturated

Suction Temperature

exceeds Cooler Leaving

Fluid Temperature

Faulty expansion valve,

suction pressure transducer

or leaving fluid thermistor

(T1).

Circuit A shutdown after

pumpdown complete.

Automatic Faulty expansion valve or

suction pressure transducer

(T5) or leaving fluid

thermistor (T1).

T078

Alert

Circuit B Saturated

Suction Temperature

exceeds Cooler Leaving

Fluid Temperature

Faulty expansion valve,

suction pressure transducer

or leaving fluid thermistor

(T1).

Circuit B shutdown after

pumpdown complete

Automatic Faulty expansion valve or

suction pressure transducer

(T6) or leaving fluid

thermistor (T1).

T079

Alert

Lead/Lag LWT

Thermistor Failure

Thermistor outside range of

–40 to 245 F (–40 to 118 C)

Chiller runs as a stand

alone machine

Automatic Dual LWT thermistor failure,

damaged cable/wire or

wiring error.

T090

Alert

Circuit A Discharge

Pressure Transducer Failure

Voltage ratio more than

99.9% or less than .5%.

Circuit A shut down

Automatic Transducer failure, poor

connection to MBB, or wiring

damage/error.

T091

Alert

Circuit B Discharge

Pressure Transducer Failure

Voltage ratio more than

99.9% or less than .5%.

Circuit B shut down

Automatic Transducer failure, poor

connection to MBB, or wiring

damage/error.

T092

Alert

Circuit A Suction

Pressure Transducer Failure

Voltage ratio more than

99.9% or less than .5%.

Circuit A shut down

Automatic Transducer failure, poor

connection to MBB, or wiring

damage/error.