Head pressure control, Fig. 14 — 30ra condenser fan sequence – Sterling AquaSnap 30RA010-055 User Manual

Page 21

21

Head Pressure Control —

The Main Base Board

(MBB) controls the condenser fans to maintain the lowest

condensing temperature possible, and thus the highest unit

efficiency. The MBB uses the saturated condensing tempera-

ture input from the discharge pressure transducer to control the

fans. Head pressure control is maintained through a calculated

set point which is automatically adjusted based on actual

saturated condensing and saturated suction temperatures so

that the compressor(s) is (are) always operating within the

manufacturer's specified envelope (see Fig. 13). The control

will automatically reduce the unit capacity as the saturated

condensing temperature approaches an upper limit. The

control will indicate through an alert that a high ambient

unloading mode is in effect. If the saturated condensing

temperature in a circuit exceeds the calculated maximum, the

circuit will be stopped. For these reasons, there are no head

pressure control methods or set points to enter. If the saturated

condensing temperature in a circuit is greater than or equal to

95 F (35 C) at start-up, all available condenser fans will be

started to prevent excessive discharge pressure during

pull-down. The control will turn off a fan stage when the

condensing temperature has been below the calculated head

pressure set point by 35 F (19.4 C) for more than 2 minutes.

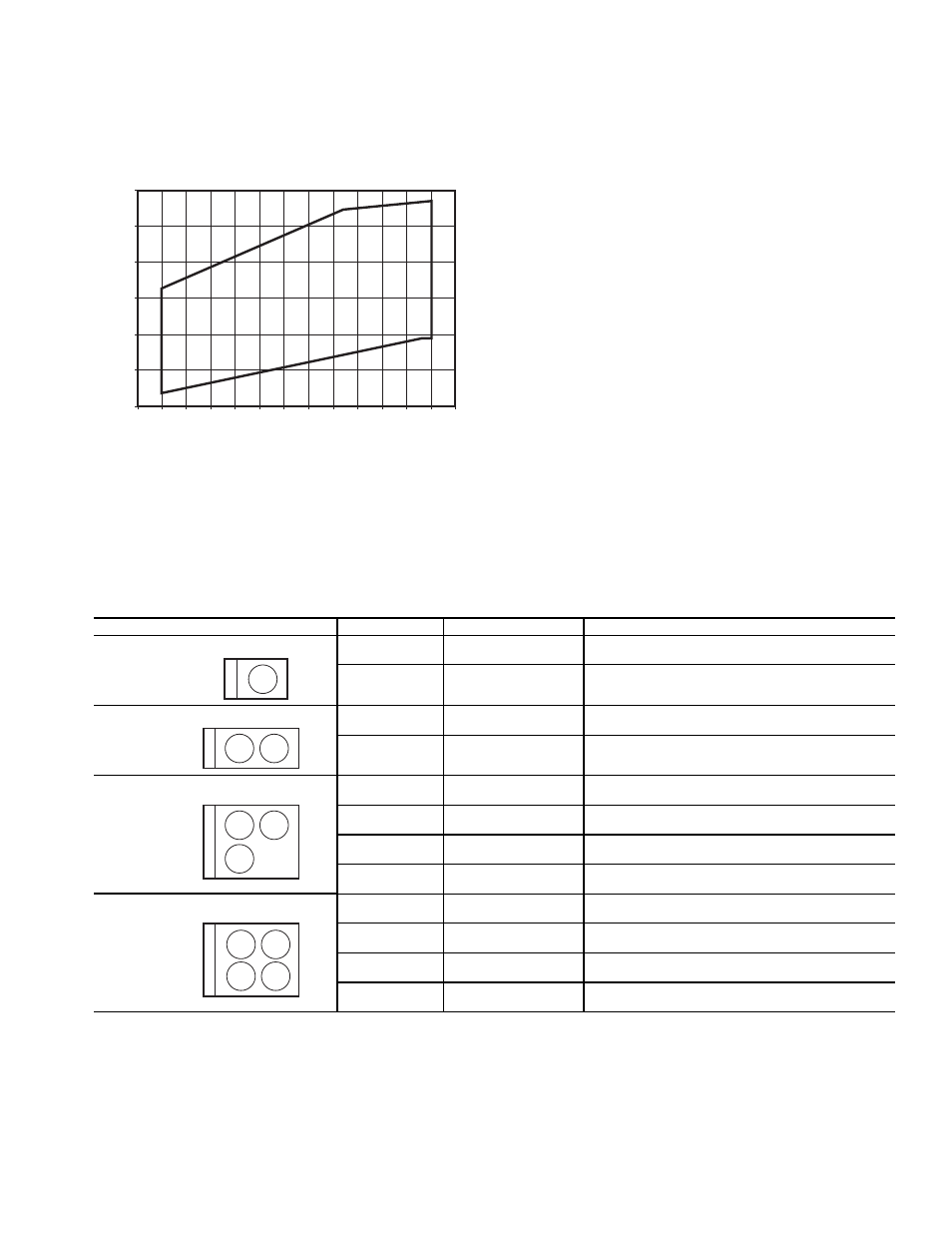

Fan sequences are shown in Fig. 14.

MOTORMASTER® V OPTION — For low-ambient opera-

tion, the lead fan on a circuit can be equipped with the

Motormaster V head pressure controller option or accessory.

The control will automatically raise the head pressure set point

by 5 F (2.8 C) when Motormaster control is configured. The

controller is energized with the first fan stage and adjusts fan

speed to maintain a liquid pressure of 135 psig (931 kPa). For

sizes 010-018 and Circuit B of sizes 032-040, the two-speed

fan is wired for high speed operation and the Motormaster V

controller adjusts fan speed. For size 022-030, 042-055 and

circuit A of the 032-040 sizes, the lead fan (A1 or B1) in the

circuit is controlled. Refer to Fig. 14 for condenser fan staging

information. Refer to Fig. 15 for typical pressure transducer

location.

LEGEND

Fig. 13 — Operating Envelope for

R-22 Maneurop Compressor

SCT

—

Saturated Condensing Temperature

SST

—

Saturated Suction Temperature

-10

-5

40

60

80

100

120

160

140

0

5

10

15

20

25

30

35

40

45

50

55

R-22 SST (F)

SCT

(F)

105

149

47.5

154

78

FAN ARRANGEMENT

FAN NO.

FAN RELAY

NORMAL CONTROL

30RAN010-018

1

FC-LS

Energize Fan at

Low Speed

1

FC-HS

Energize Fan at

High Speed

30RAN022-030

1

FC-A1

First Stage

Condenser Fan

2

FC-A2

Second Stage

Condenser Fan

30RAN032-040

1

FC-A1

On with Compressor A1

and/or Compressor A2

2

FC-A2

First Stage Condenser

Fan, Circuit A

3

FC-LS

Low Speed, Fan on

w/Compressor B1

3

FC-HS

Energize Fan at High Speed,

Circuit B

30RAN042-055

1

FC-A1

On with Compressor A1

and/or Compressor A2

2

FC-A2

First Stage Condenser Fan,

Circuit A

3

FC-B1

On with Compressor B1

and/or Compressor B2

4

FC-B2

First Stage Condenser Fan,

Circuit B

CONTROL

BOX

END

1

CONTROL

BOX

END

1

2

1

2

CONTROL

BOX

END

3

CONTROL

BOX

END

1

2

3

4

Fig. 14 — 30RA Condenser Fan Sequence