Service test (see table 11) – Sterling AquaSnap 30RA010-055 User Manual

Page 23

23

Table 8 — Control Methods and Cooling Set Points

*Dual set point switch input used. CSP1 used when switch input is open. CSP2 used when switch input is closed.

†Cooling set point determined from 4 to 20 mA input to Energy Management Module (EMM) to terminals TB6-3,5.

HEATING

OPERATION — The chiller can be used for

pump outputs or optional factory-installed hydronic system

operation can be utilized for heating applications. The heating

mode is activated when the control sees a field-supplied closed

switch input to terminal block TB5-7,8. The control locks out

cooling when the heat relay input is seen. A field-supplied

boiler relay connection is made using heat relay and alarm

relay contacts. Factory-installed ‘BOILER’ connections exist

in the control panel near TB5 for these applications. Alarms

and alerts A189 through A202 are active during heating

operation.

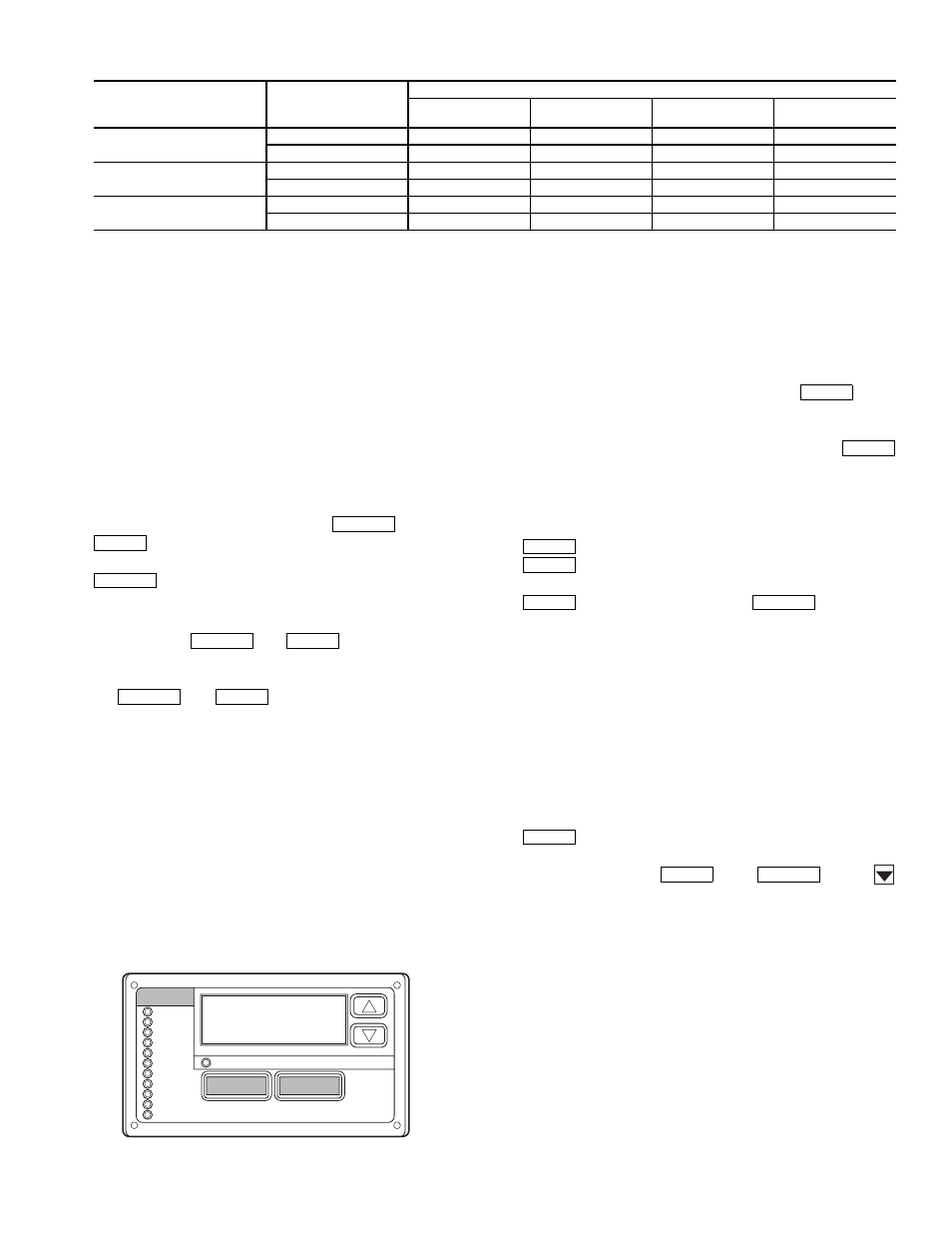

Marquee Display Usage (See Fig. 16 and

Tables 8-27) —

The Marquee display module provides the

user interface to the ComfortLink™ control system. The

display has up and down arrow keys, an

key, and an

key. These keys are used to navigate through the

different levels of the display structure. See Table 9. Press the

key until the display is blank to move through the

top 11 mode levels indicated by LEDs on the left side of the

display.

Pressing the

and

keys simultaneously

will scroll a clear language text description across the display

indicating the full meaning of each display acronym. Pressing

the

and

keys when the display is blank

(Mode LED level) will return the Marquee display to its default

menu of rotating display items. In addition, the password will

be disabled requiring that it be entered again before changes

can be made to password protected items.

Clear language descriptions in English, Spanish, French, or

Portuguese can be displayed when properly configuring the

LANG Item in the Configuration Mode, under the Display

(DISP) submode. See Table 17. Throughout this text, the loca-

tion of items in the menu structure will be described in the fol-

lowing format:

Item Expansion (ITEM) [Mode Name, Sub-mode Name]

For example, using the language selection item:

Language Selection (LANG) [Configuration, DISP]

NOTE: When the LANG variable is changed to 1, 2, or 3, all

appropriate display expansions will immediately change to the

new language. No power-off or control reset is required when

reconfiguring languages.

When a specific item is located, the display will flash show-

ing the operator, the item, followed by the item value and then

followed by the item units (if any). Press the

key to

stop the display at the item value. Items in the Configuration

and Service Test modes are password protected. The display

will flash PASS and WORD when required. Use the

and arrow keys to enter the 4 digits of the password. The

default password is 1111.

Changing item values or testing outputs is accomplished in

the same manner. Locate and display the desired item. Press

to stop the display at the item value. Press the

key again so that the item value flashes. Use the

arrow keys to change the value or state of an item and press the

key to accept it. Press the

key and the

item, value, or units display will resume. Repeat the process as

required for other items.

See Tables 8-27 for further details.

Service Test (See Table 11) —

Both main power

and control circuit power must be on.

The Service Test function should be used to verify proper

operation of condenser fan(s), compressors, minimum load

valve solenoid (if installed), cooler pump(s) and remote alarm

relay. To use the Service Test mode, the Enable/Off/Remote

Contact switch must be in the OFF position. Use the display

keys and Table 11 to enter the mode and display TEST. Press

twice so that OFF flashes. Enter the password if

required. Use either arrow key to change the TEST value to the

ON position and press

. Press

and the

button to enter the OUTS or COMP sub-mode.

Test the condenser fans, cooler pump(s) and alarm relay by

changing the item values from OFF to ON. These discrete

outputs are then turned off if there is no keypad activity for

10 minutes. Test the compressor and minimum load valve

solenoid (if installed) outputs in a similar manner. The

minimum load valve solenoids will be turned off if there is no

keypad activity for 10 minutes. Compressors will stay on until

they are turned off by the operator. The Service Test mode will

remain enabled for as long as there is one or more compressors

running. All safeties are monitored during this test and will turn

a compressor, circuit or the machine off if required. Any other

mode or sub-mode can be accessed, viewed, or changed during

the TEST mode. The STAT item [Run/Status, VIEW] will dis-

play “0” as long as the Service mode is enabled. The TEST

sub-mode value must be changed back to OFF before the chill-

er can be switched to Enable or Remote contact for normal

operation.

CONTROL

TYPE

(CTRL)

OCCUPANCY

STATE

COOLING SET POINT SELECT (CLSP)

0

(single)

1

(dual, switch)

2

(dual, occ)

3

(4 to 20 mA)

0 (switch)

Occupied

ON,CSP1

ON*

ON,CSP1

ON†

Unoccupied

ON,CSP1

ON*

ON,CSP2

ON

2 (Occupancy)

Occupied

ON,CSP1

ON*

Illegal

ON†

Unoccupied

OFF

OFF

Illegal

OFF

3 (

SCN)

Occupied ON,CSP1 ON* ON,CSP1 ON†

Unoccupied

ON,CSP1

ON*

ON,CSP2

ON†

ESCAPE

ENTER

ESCAPE

ESCAPE

ENTER

ESCAPE

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ESCAPE

ENTER

ENTER

ESCAPE

Run Status

Service Test

Temperature

Pressures

Setpoints

Inputs

Outputs

Configuration

Time Clock

Operating Modes

Alarms

Alarm Status

ENTER

MODE

ESCAPE

Fig. 16 — Scrolling Marquee Display