Name (type) specifications, structure, etc, Application condition, Circuit configuration and connection – MITSUBISHI ELECTRIC INVERTER FR-F700 User Manual

Page 55

Features

Standard

Specifications

Outline

Dimension

Drawings

Operation

Panel

Protective

Functions

Options

Instructions

Motor

Compatibility

W

arranty

Inquiry

Peripheral Devices

Why energy

savings?

Te

rminal Connection

Diagram

Te

rminal Specification

Explanation

Parameter

List

Explanations

of

Parameters

56

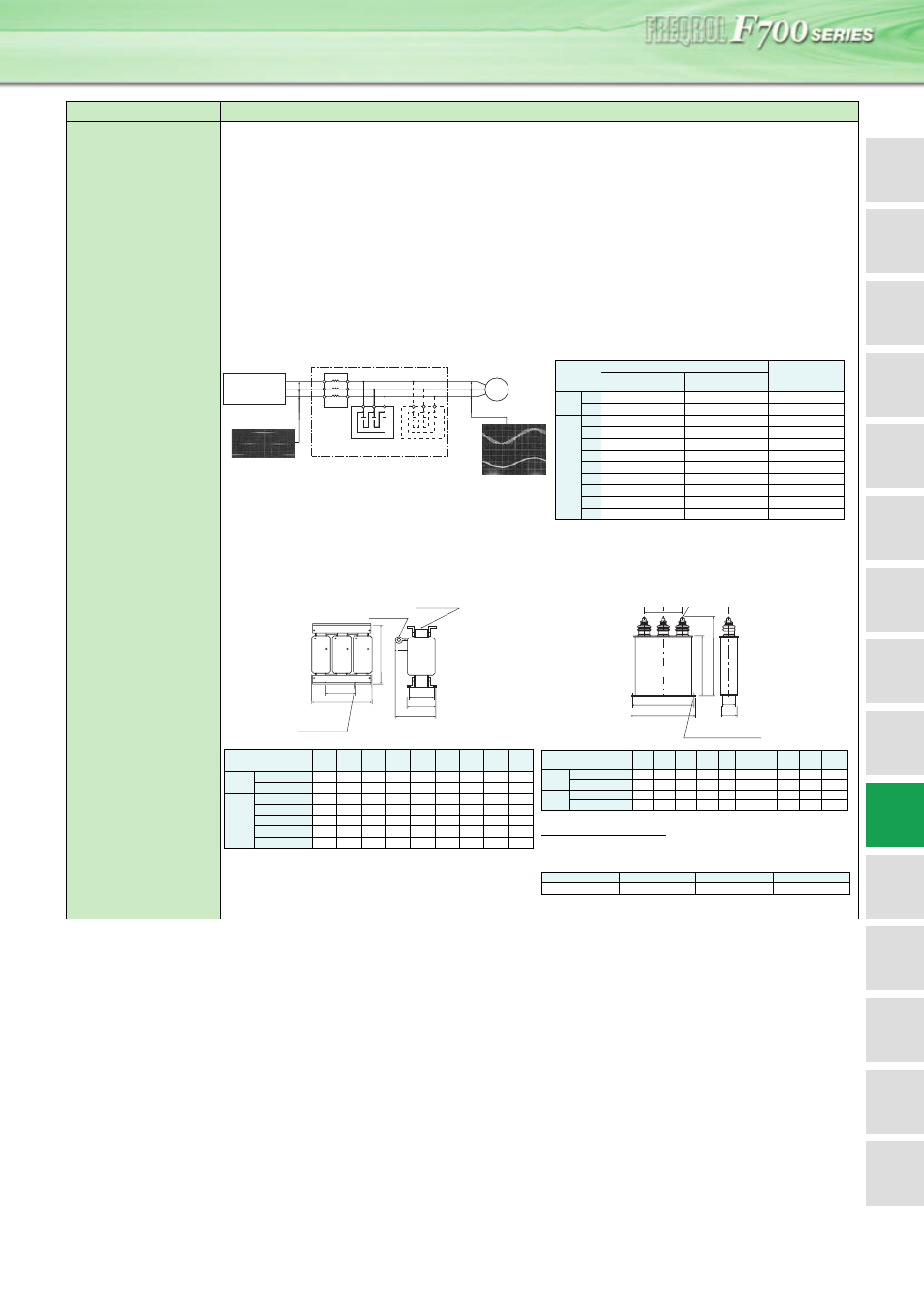

Sine wave filter

MT-BSL-(H)

K

MT-BSC-(H)

K

Application of the sine wave filter

For the FR-F700 series (75K or more) inverter, the motor voltage and current can be made to nearly sine wave shaped by providing a sine wave filter

on the output side.

1) Low noise

2) Surgeless

3) Motor loss reduction (use of standard motor)

Application condition

The following conditions have to be satisfied to install the sine wave filter.

1) Change the

Pr. 72

setting to "25". (The initial value is "2".)

The carrier frequency changes to 2.5KHz. (The sine wave filter is designed on condition that the carrier frequency is 2.5KHz. Be sure to change

the setting properly.) If the inverter is operated with Pr.72 set to other than "25", the inverter and sine wave filter may be damaged.

2) The sine wave filter can be used only for 60 Hz or less inverter frequency.

Note that the filter can not be used for the higher frequency operation than this. (Otherwise the filter loss will increase. )

3) Use the inverter with capacity one rank higher. *2

4) Install an external thermal relay of the motor.

Circuit configuration and connection

Name (type)

Specifications, Structure, etc.

Sine wave filter

FR-F700

Inverter

(Carrier 2.5kHz)

Inverter output

voltage

wave form

Capacitor

(Capacitor)

Wave form at a

motor terminal

IM

Motor

U

V

W

X

Y

Z

voltage

current

+

-

0

Reactor

Install the filter near the inverter.

For a capacitor cable, use a cable

with size larger than indicated in the

table below "recommended cable

size ".

*

Motor

capacity

(kW)

Inverter type

Applied Inverter

(*2)

Reactor for filter

Capacitor for filter

200V

class

75

MT-BSL-75K

1

×MT-BSC-75K

FR-F720-90K

90

MT-BSL-90K

1

×MT-BSC-90K

FR-F720-110K

400V

class

75

MT-BSL-H75K

1

×MT-BSC-H75K

FR-F740-90K

90

MT-BSL-H110K

1

×MT-BSC-H110K

FR-F740-110K

110

MT-BSL-H110K

1

×MT-BSC-H110K

FR-F740-132K

132

MT-BSL-H150K

2

×MT-BSC-H75K

FR-F740-160K

160

MT-BSL-H220K

2

×MT-BSC-H110K

FR-F740-185K

185

MT-BSL-H220K

2

×MT-BSC-H110K

FR-F740-220K

220

MT-BSL-H220K

2

×MT-BSC-H110K

FR-F740-250K

250

MT-BSL-H280K

3

×MT-BSC-H110K

FR-F740-280K

280

MT-BSL-H280K

3

×MT-BSC-H110K

FR-F740-315K

*1

For the 2

×

, connect capacitors in parallel as in the connection

diagram.

*2

If the rated motor current

×

(1.05 to 1.1) is less than 80% of the

inverter rated current, an inverter with same kW with a motor

can be used.

Reactor for sine wave filter

Capacitor for sine wave filter

* Leave more than 25mm space between capacitors.

Recommended cable size

The cable sizes between the Inverter and MT-BSL and between the MT-

BSL and IM depend on U, V, W of "Peripheral devices list" (page 57)

The cable size to the MT-BSC is as table below.

Inverter type

A

B

C

D

E

F

G

H

Mass

(kg)

200V

class

MT-BSL-75K

330

150

285

185

216

328

M10

M12

80

MT-BSL-90K

390

150

320

180

220

330

M12

M12

105

400V

class

MT-BSL-H75K

330

150

285

185

216

318

M10

M10

80

MT-BSL-H110K 390

150

340

195

235

368

M12

M12

140

MT-BSL-H150K 455

200

397

200

240

380

M12

M12

190

MT-BSL-H220K 495

200

405

250

300

420

M12

M12

240

MT-BSL-H280K 575

200

470

310

370

485

M12

M12

340

C

B

A

4-G

installation

hole

W

Z

V

Y

U

X

Terminal H

Rating plate

D

E

F

Inverter type

A

B

C

D

E

F

G

H

I

Mass

(kg)

200V

class

MT-BSC-75K

205 190

285 230

70

40

40

φ7

M6

3.9

MT-BSC-90K

280 265

270 180

90

55

80

φ7

M12

5.5

400V

class

MT-BSC-H75K

205 190

220 170

70

40

50

φ7

M6

3.0

MT-BSC-H110K

205 190

280 230

70

40

50

φ7

M6

4.0

MT-BSC-75K

MT-BSC-90K

MT-BSC-H75K

MT-BSC-H110K

38mm

2

38mm

2

22mm

2

22mm

2

B

A

Terminals I

G

G

4-H

Installation hole

D

C

E

F