Stall prevention operation – MITSUBISHI ELECTRIC INVERTER FR-F700 User Manual

Page 29

Features

Standard

Specifications

Outline

Dimension

Drawings

Operation

Panel

Protective

Functions

Options

Instructions

Motor

Compatibility

W

arranty

Inquiry

Peripheral Devices

Why energy

savings?

Te

rminal Connection

Diagram

Te

rminal Specification

Explanation

Parameter

List

Explanations

of

Parameters

30

indicates simple mode parameters and

indicates extended parameters. When setting parameters, refer to the instruction manual (applied) and understand instructions.

Pr.

Pr.

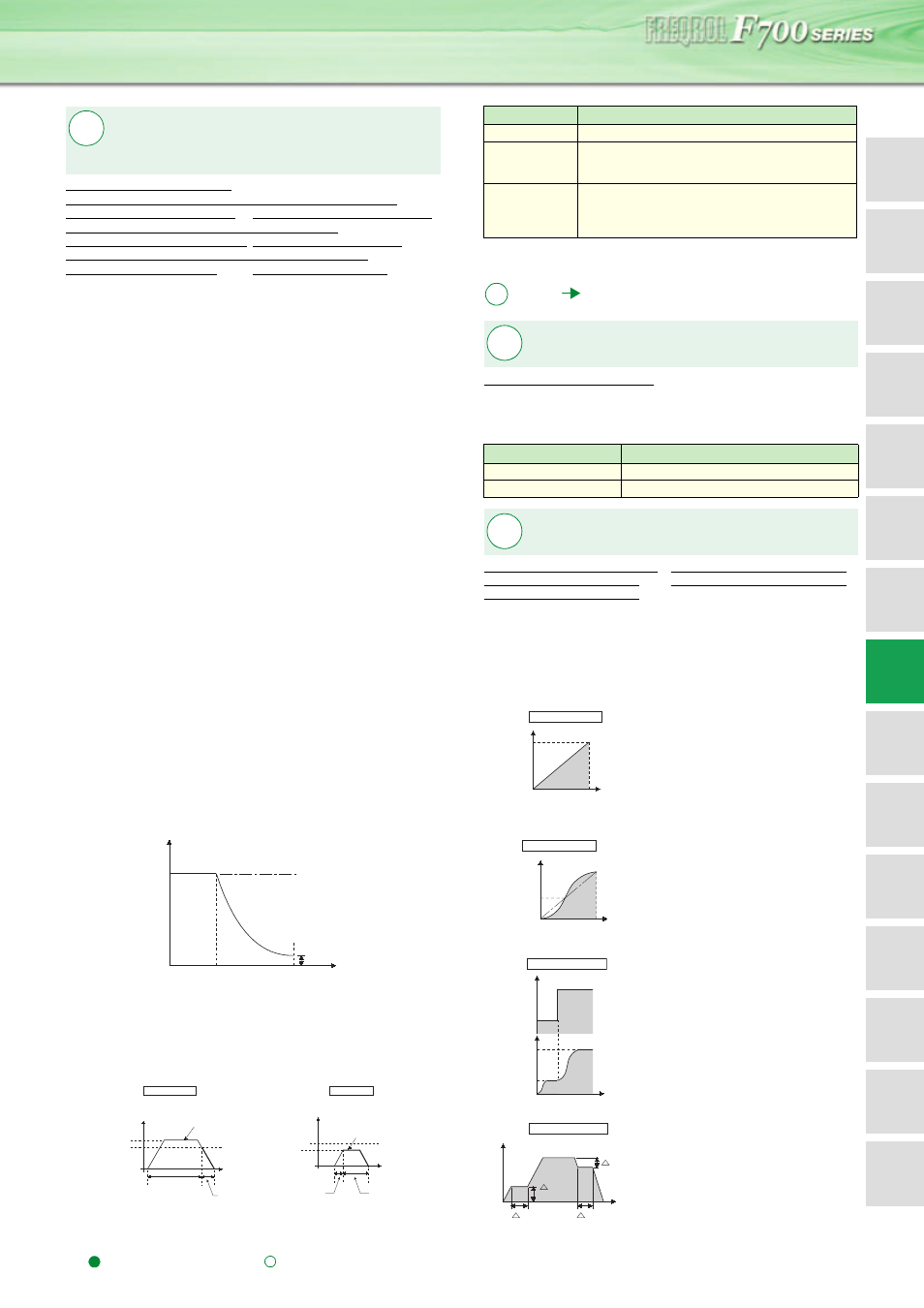

This function monitors the output current and automatically changes

the output frequency to prevent the inverter from coming to an alarm

stop due to overcurrent, overvoltage, etc. It can also limit stall

prevention and fast-response current limit operation during

acceleration/deceleration, driving or regeneration.

Stall prevention

If the output current exceeds the limit value, the output frequency

of the inverter is automatically varied to reduce the output current.

Also the second stall prevention function can restrict the output

frequency range in which the stall prevention function is valid.

(Pr.49)

Fast-response current limit

If the current exceeds the limit value, the output of the inverter is

shut off to prevent an overcurrent.

Set in Pr. 22 the ratio of the output current to the rated inverter

current at which stall prevention operation will be performed.

Normally set this parameter to120% (initial value).

When “9999” is set in Pr. 22, stall prevention operation level can be

changed by the signal to the auxiliary input terminal (terminal 1). For

the adjustment of bias/gain of analog signal, use Pr. 148 and Pr. 149.

During high-speed operation above the rated motor frequency,

acceleration may not be made because the motor current does

not increase. If operation is performed in a high frequency range,

the current at motor lockup becomes smaller than the rated output

current of the inverter, and the protective function (OL) is not

executed if the motor is at a stop.

To improve the operating characteristics of the motor in this case,

the stall prevention level can be reduced in the high frequency

region. This function is effective for performing operation up to the

high speed region on a centrifugal separator etc. Normally, set

60Hz in Pr. 66 and 100% in Pr. 23.

By setting "9999" (initial value) in Pr. 23 Stall prevention operation

level compensation factor at double speed, the stall prevention

operation level is constant at the Pr. 22 setting up to 400Hz.

Setting "9999" in Pr. 49 Second stall prevention operation frequency

and turning the RT signal on make Pr. 48 Second stall prevention

operation current valid.

The stall prevention operation level from 0Hz to the output

frequency set in Pr. 49 can be set in Pr. 48.

Stall prevention operation and fast response current restriction function

can be restricted according to the operation condition using Pr. 156.

By inputting the frequency setting compensation signal (terminal 1,

2), the speed (frequency) can be compensated for relative to the

multi-speed setting or the speed setting by remote setting function.

You can set the acceleration/deceleration pattern suitable for

application.

You can also set the backlash measures that stop acceleration/

deceleration once at the parameter-set frequency and time

during acceleration/deceleration.

Stall prevention operation

Pr.22 Stall prevention operation level

Pr.23 Stall prevention operation level compensation factor at double speed

Pr.48 Second stall prevention operation current

Pr.49 Second stall prevention operation frequency

Pr.66 Stall prevention operation reduction starting frequency

Pr.148 Stall prevention level at 0V input. Pr.149 Stall prevention level at 10V input.

Pr.154 Voltage reduction selection during stall prevention operation

Pr.156 Stall prevention operation selection

Pr.157 OL signal output timer

Pr.

22, 23, 48, 49, 66, 148, 149, 154, 156, 157

Output frequency (Hz)

Pr.22

Pr.23

When Pr.23=9999

Pr.66

400Hz

Stall prevention operation

level (%)

Reduction ratio compensation

factor (%)

Pr. 22

used

Pr.49

Pr. 48

used

Output

frequency (Hz)

Output

frequency

Set

frequency

Set frequency is Pr. 49 or less

Time

Pr. 22

used

Pr.49

Output

frequency (Hz)

Output

frequency

Stall

prevention

level

Set frequency exceeds Pr. 49

Pr. 48

used

Set

frequency

Time

Pr. 49 Setting

Operation

0 (initial value)

Second stall prevention function is not activated

0.01Hz to 400Hz

If the output frequency is less than the frequency set in

Pr. 49, the second stall prevention operation function is

activated. (during constant speed or deceleration)

9999

The second stall prevention function is performed according to

the RT signal.

RT signal on ....... Stall level Pr. 48

RT signal off ....... Stall level Pr. 22

24 to 27

Refer to the section about Pr.4 to Pr.6

Input compensation of multi-

speed and remote setting

Pr.28 Multi-speed input compensation selection

Pr. 28 Setting

Definition

0 (initial value)

Without compensation

1

With compensation

Acceleration/ deceleration pattern

and back lash measures

Pr.29 Acceleration/deceleration pattern selection

Pr.140 Backlash acceleration stopping frequency

Pr.141 Backlash acceleration stopping time

Pr.142 Backlash deceleration stopping frequency

Pr.143 Backlash deceleration stopping time

Linear acceleration/deceleration

(setting "0", initial value)

⋅ When the frequency is changed for

acceleration, deceleration, etc. in

inverter operation, the output

frequency is changed linearly (linear

acceleration/deceleration) to reach

the set frequency without straining

the motor and inverter.

S-pattern acceleration/deceleration A

(setting "1")

⋅ For machine tool spindle

applications, etc.

Use when acceleration/deceleration

must be made in a short time to a

high-speed region of not lower than

base frequency.

S-pattern acceleration/deceleration B

(setting "2")

⋅ For prevention of load shifting in

conveyor and other applications

Since acceleration/deceleration is

always made in an S shape from

current frequency (f2) to target

frequency (f1), this function eases

shock produced at acceleration/

deceleration and is effective for load

collapse prevention, etc.

Backlash measures (setting "3", Pr.140

to Pr.143 )

⋅ To avoid backlash, acceleration/

deceleration is temporarily stopped.

Set the acceleration/deceleration

stopping frequency and time in Pr.

140 to Pr. 143.

Pr.

Pr.

28

Pr.

29, 140 to 143

Setting value "0"

[Linear acceleration

/ deceleration]

Output frequency

(Hz)

Time

fb

Output frequency

(Hz)

Setting value "1"

Time

[S-pattern acceleration

/deceleration A]

f1

Setting value "2"

[S-pattern acceleration

/deceleration B]

f2

Time

Set frequency

(Hz)

Output frequency

(Hz)

[Anti-backlash measure

function]

f2

Pr.142

Pr.143

Pr.141

Pr.140

Time

Output frequency (Hz)

Setting value "3"

t1

t2

f1