Remote output function (rem signal), Current average value monitor signal – MITSUBISHI ELECTRIC INVERTER FR-F700 User Manual

Page 43

Features

Standard

Specifications

Outline

Dimension

Drawings

Operation

Panel

Protective

Functions

Options

Instructions

Motor

Compatibility

W

arranty

Inquiry

Peripheral Devices

Why energy

savings?

Te

rminal Connection

Diagram

Te

rminal Specification

Explanation

Parameter

List

Explanations

of

Parameters

44

indicates simple mode parameters and

indicates extended parameters. When setting parameters, refer to the instruction manual (applied) and understand instructions.

Pr.

Pr.

When the RS-485 terminals or communication option is used,

the external operation command and speed command can be

made valid. Also, the control command source in the PU

operation mode can be selected.

* Pr. 550 and Pr. 551 are always write-enabled.

You can utilize the on/off of the inverter's output signals instead

of the remote output terminal of the programmable logic

controller.

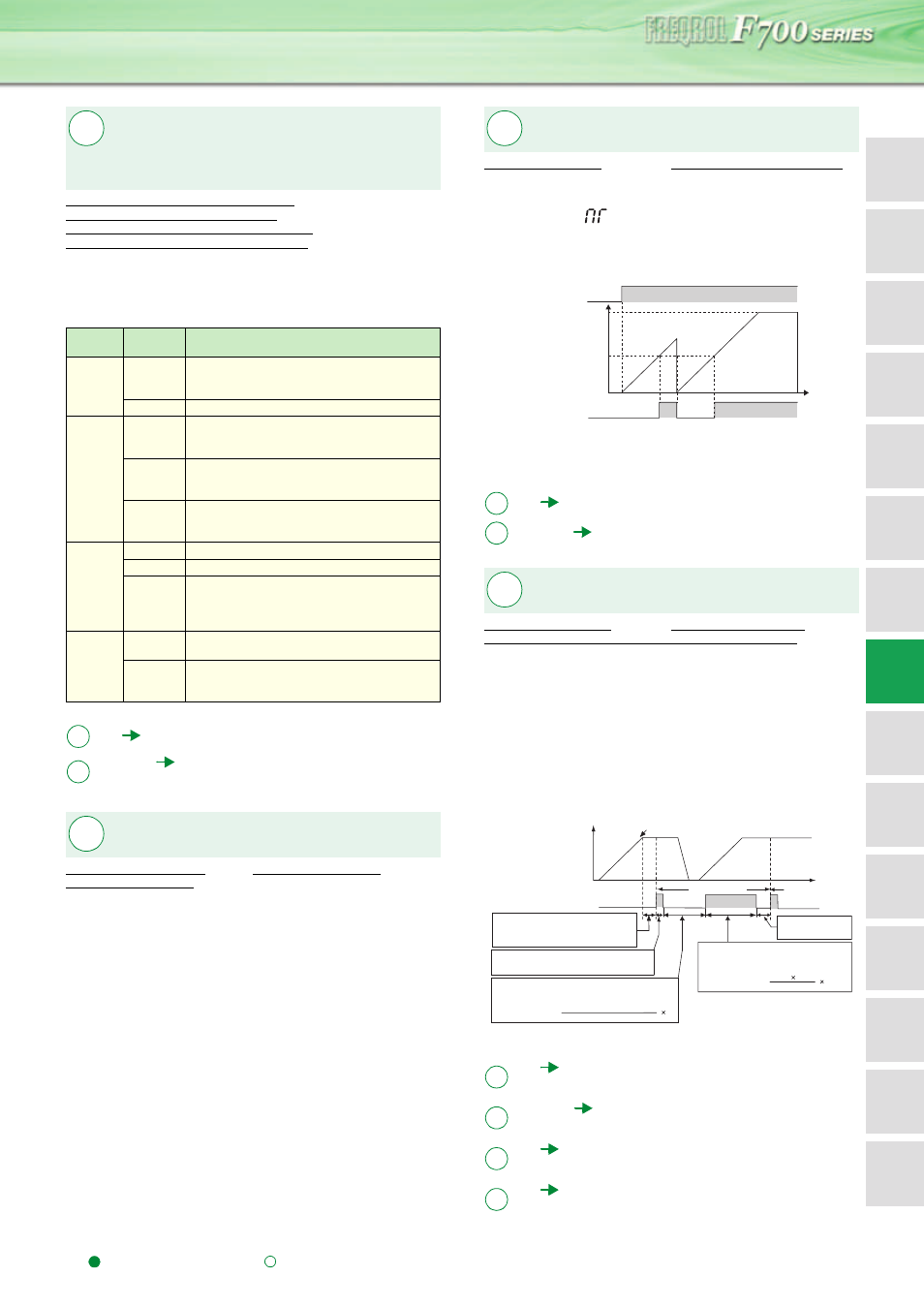

When the cumulative energization time of the inverter reaches

the parameter set time, the maintenance timer output signal

(Y95) is output.

(MT) is displayed on the operation panel

(FR-DU07)

This can be used as a guideline for the maintenance time of

peripheral devices.

The cumulative energization time of the inverter is stored into the

EEPROM every hour and indicated in Pr. 503 Maintenance timer in

100h increments. Pr. 503 is clamped at 9998 (999800h).

The average value of the output current during constant speed

operation and the maintenance timer value are output as a pulse to

the current average value monitor signal (Y93).

The pulse width output to the I/O module of the PLC or the like can

be used as a guideline due to abrasion of machines and elongation

of belt and for aged deterioration of devices to know the

maintenance time.

The current average value monitor signal (Y93) is output as

pulse for 20s as 1 cycle and repeatedly output during constant

speed operation.

Operation command source and speed command

source during communication operation

Pr.338 Communication operation command source

Pr.339 Communication speed command source

Pr.550 NET mode operation command source selection

Pr.551 PU mode operation command source selection

Pr.

Number

Setting

Range

Description

338

0

(initial

value)

Operation command source communication

1

Operation command source external

339

0

(initial

value)

Speed command source communication

1

Speed command source external (Frequency

setting from communication is invalid, terminal 2

and 1 setting from external is valid)

2

Speed command source external (Frequency

setting from communication is valid, terminal 2 and

1 setting from external is invalid)

550

*

0

Communication option valid

1

Inverter RS-485 terminal valid

9999

(initial

value)

Automatic communication option recognition

Normally, the RS-485 terminals are valid. When

the communication option is fitted, the

communication option is valid.

551

*

1

Select the RS-485 terminals as the PU operation

mode control source.

2

(initial

value)

Select the PU connector as the PU operation

mode control source.

340

Refer to the section about Pr. 79.

341 to 343

Refer to the section about Pr. 117 and

other relevant parameters.

Remote output function

(REM signal)

Pr.495 Remote output selection

Pr.496 Remote output data 1

Pr.497 Remote output data 2

Pr.

338, 339, 550, 551

Pr.

Pr.

Pr.

495 to 497

To determine the

maintenance time of parts.

Pr.503 Maintenance timer

Pr.504 Maintenance timer alarm output set time

549

Refer to the section about Pr.117 to Pr. 124.

550 to 551

Refer to the section about Pr. 338, Pr.339.

Current average value

monitor signal

Pr.555 Current average time

Pr.556 Data output mask time

Pr.557 Current average value monitor signal output reference current

571

Refer to the section about Pr. 13 and other

relevant parameters.

575 to 577

Refer to the section about Pr. 127 and

other relevant parameters.

611

Refer to the section about Pr. 57 and other

relevant parameters.

872

Refer to the section about Pr. 251 and other

relevant parameters.

Pr.

503 to 504

First power

ON

Maintenance

timer

(Pr. 503)

Set "0" in Pr.503

Y95 signal

MT display

OFF

ON

Time

ON

Pr.504

9998

(999800h)

Pr.

Pr.

Pr.

555 to 557

Y93 signal

1) Data output mask time

2) Start pulse

1 cycle (20s)

3) Output current average value pulse

Next cycle

Time

Output

frequency

From acceleration to constant speed operation

Signal output time=

output current average value (A)

Pr.557 (A)

5s

4) Maintenance timer pulse

Signal output time=

5s

40000h

5) End pulse

The averaged current value is output as low pulse shape for

0.5 to 9s (10 to 180%) during start bit output.

When the speed has changed to constant

from acceleration/deceleration, Y93 signal is

not output for Pr.556 time.

Pr.503 1000h

output as low pulse

shape for 1 to 16.5s

The maintenance timer value (Pr.503) is output

as Hi output pulse shape for 2 to 9s (16000h to

72000h).

Output as Hi pulse shape for 1s (fixed)

Time and output current set in Pr.555 are averaged

Pr.

Pr.

Pr.

Pr.