Pid control, 3) analog input display unit changing (pr. 241) – MITSUBISHI ELECTRIC INVERTER FR-F700 User Manual

Page 38

39

indicates simple mode parameters and

indicates extended parameters. When setting parameters, refer to the instruction manual (applied) and understand instructions.

Pr.

Pr.

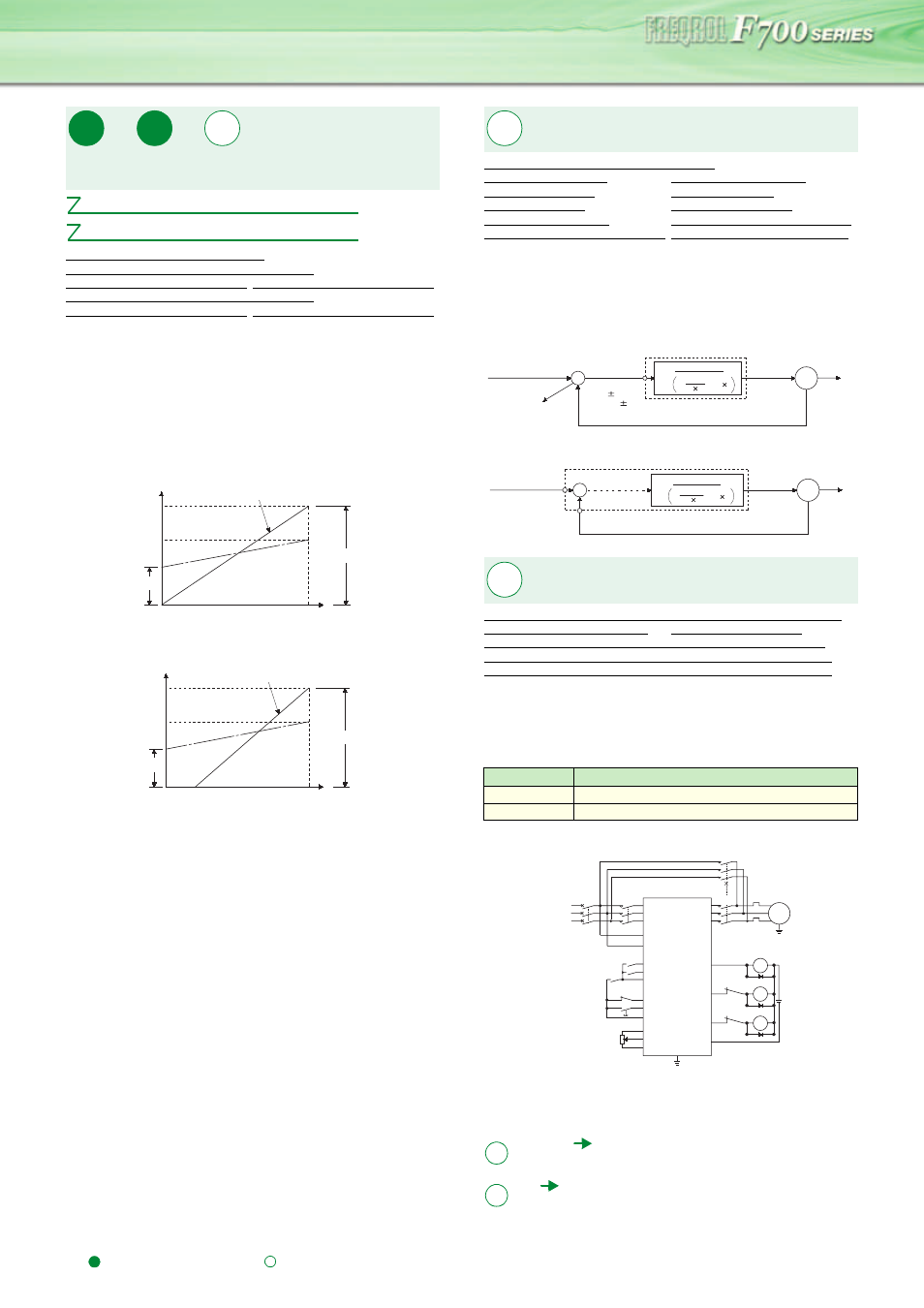

You can set the magnitude (slope) of the output frequency as

desired in relation to the frequency setting signal (0 to 5VDC, 0 to

10V or 4 to 20mA).

(1) Change the frequency at maximum analog input.

(Pr.125, Pr.126)

Set a value in Pr. 125 (Pr. 126) when changing only the

frequency setting (gain) of the maximum analog input power

(current). (C2 (Pr. 902) to C7 (Pr. 905) setting need not be

changed)

(2) Analog input bias/gain calibration

(C2(Pr.902) to C7(Pr.905))

⋅ The "bias" and "gain" functions are used to adjust the

relationship between the input signal entered from outside

the inverter to set the output frequency, e.g. 0 to 5V, 0 to 10V

or 4 to 20mADC, and the output frequency.

⋅ Set the bias frequency of terminal 2 input using C2(Pr. 902).

(Factory-set to the frequency at 0V)

⋅ Using Pr. 125 , set the output frequency relative to the

frequency command voltage (current) set in Pr. 73 Analog

input selection.

⋅ Set the bias frequency of the terminal 4 input using C5(Pr.

904).

(Factory-set to the frequency at 4mA)

⋅ Using Pr. 126 , set the output frequency relative to 20mA of

the frequency command current (4 to 20mA).

(3) Analog input display unit changing (Pr. 241)

⋅ You can change the analog input display unit (%/V/mA) for

analog input bias/gain calibration.

The inverter can be used to exercise process control, e.g. flow

rate, air volume or pressure.

The terminal 2 input signal or parameter setting is used as a set point

and the terminal 4 input signal used as a feedback value to constitute

a feedback system for PID control.

⋅ Pr.128 ="10, 11" (Deviation value signal input)

⋅ Pr.128 ="20, 21" (Measured value input)

The complicated sequence circuit for commercial power supply-

inverter switchover is built in the inverter. Hence, merely

inputting the start, stop or automatic switchover selection signal

facilitates the interlock operation of the switchover magnetic

contactor.

Sink logic type, Pr.185 = "7", Pr.192 = "17", Pr.193 = "18", Pr.194 = "19"

*1 Take caution for the capacity of the sequence output terminal.

*2 When connecting a DC power supply, insert a protective diode.

*3 The used terminal changes depending on the setting of Pr. 180 to Pr. 189

(input terminal function selection).

Analog input frequency change and voltage, current input and

frequency adjustment (calibration)

Pr. 241 Analog input display unit switchover

C2(Pr.902) Terminal 2 frequency setting bias frequency

C3(Pr.902) Terminal 2 frequency setting bias C4(Pr.903) Terminal 2 frequency setting gain

C5(Pr.904) Terminal 4 frequency setting bias frequency

C6(Pr.904) Terminal 4 frequency setting bias C7(Pr.905) Terminal 4 frequency setting gain

Pr.

125

Pr.

126

Pr.

241, C2(902) to C7(905)

Pr.125 Terminal 2 frequency setting gain frequency

Pr.126 Terminal 4 frequency setting gain frequency

Output frequency

(Hz)

Pr.125

0

0

Frequency setting signal

100%

10V

Initial value

Bias

Gain

0

5V

C2

(Pr.902)

(Pr.902)

(Pr.903)

C3

C4

60Hz

Output frequency

(Hz)

Pr.126

0

Frequency setting signal

100%

Initial value

Bias

Gain

0

20

4

20mA

C5

(Pr.904)

C6 (Pr.904)

(Pr.905)

C7

60Hz

PID control

Pr.127 PID control automatic switchover freqeuncy

Pr.128 PID action selection

Pr.129 PID proportional band

Pr.130 PID integral time

Pr.131 PID upper limit

Pr.132 PID lower limit

Pr.133 PID action set point

Pr.134 PID differential time

Pr.575 Output interruption detection time

Pr.576 Output interruption detection level Pr.577 Output interruption release level

Switch between the inverter operation and

commercial power-supply operation to use

Pr.135 Commercial power-supply switchover sequence output terminal selection

Pr.136 MC switchover interlock time

Pr.137 Waiting time at a start

Pr.138 Commercial power-supply operation switchover selection at an alarm

Pr.139 Automatic switchover frequency between inverter and commercial power-supply operation

Pr.159 Automatic switchover ON range between commercial power-supply and inverter operation

Pr135 Setting

Description

0 (initial value)

Without commercial power-supply switchover sequence

1

With commercial power-supply switchover sequence

Commercial power-supply switchover sequence connection diagram

140 to 143

Refer to the section about Pr. 29 and

other relevant parameters.

144

Refer to the section about Pr. 37 and other

relevant parameters.

Pr.

127 to 134, 575 to 577

+-

IM

Deviation signal

Feedback signal (measured value)

Ti S

1

1+

+Td S

Kp

PID operation

To outside

Set point

Inverter circuit

Motor

Terminal 1

0 to 10VDC

(0 to 5V)

Kp: Proportionality constant Ti: Integral time S: Operator Td: Differential time

Manipulated

variable

+-

IM

Ti

S

Kp 1+ +Td S

1

PID operation

Pr. 133 or

terminal 2

Set point

Inverter circuit

Motor

Feedback signal (measured value)

Terminal 4

Kp: Proportionality constant Ti: Integral time S: Operator Td: Differential time

Manipulated

variable

0 to 5VDC

(0 to 10V, 4 to 20mA)

4 to 20mADC (0 to 5V, 0 to 10V)

Pr.

135 to 139, 159

Inverter start

(forward rotation)

MC1

R/L1

S/L2

T/L3

STF

R1/L11

S1/L21

CS

MRS

RES

10

2

5

U

V

W

External

thermal relay

IM

(MC1)IPF

(MC2)OL

SE

MC3

MC2

24VDC

MC

1

External

thermal reset

Frequency

setting signal

(MC3)FU

Inverter/commercial

power-supply switchover

Operation interlock

MC

2

MC

3

*3

*1

*2

*1

*1

JOG(OH)

MCCB

MC2

MC3

SD

Pr.

Pr.