E) machine cooling, Where: tc, Thermal capacity used tc – GE 489 User Manual

Page 116: Value caused by overload condition tc

4-66

489 Generator Management Relay

GE Multilin

4.10 S9 THERMAL MODEL

4 SETPOINTS

4

e) MACHINE COOLING

The 489 thermal capacity used value is reduced exponentially when the motor current is below the

OVERLOAD PICKUP

set-

point. This reduction simulates machine cooling. The cooling time constants should be entered for both stopped and run-

ning cases (the generator is assumed to be running if current is measured or the generator is offline). A machine with a

stopped rotor normally cools significantly slower than one with a turning rotor. Machine cooling is calculated using the fol-

lowing formulae:

(EQ 4.31)

(EQ 4.32)

where: TC

used

= thermal capacity used

TC

used_start

= TC

used

value caused by overload condition

TC

used_end

= TC

used

value dictated by the hot/cold curve ratio when the machine is running

(= 0 when the machine is stopped)

t

= time in minutes

τ

= Cool Time Constant (running or stopped)

I

eq

= equivalent heating current

overload_pickup = overload pickup setpoint as a multiple of FLA

hot / cold

= hot/cold curve ratio

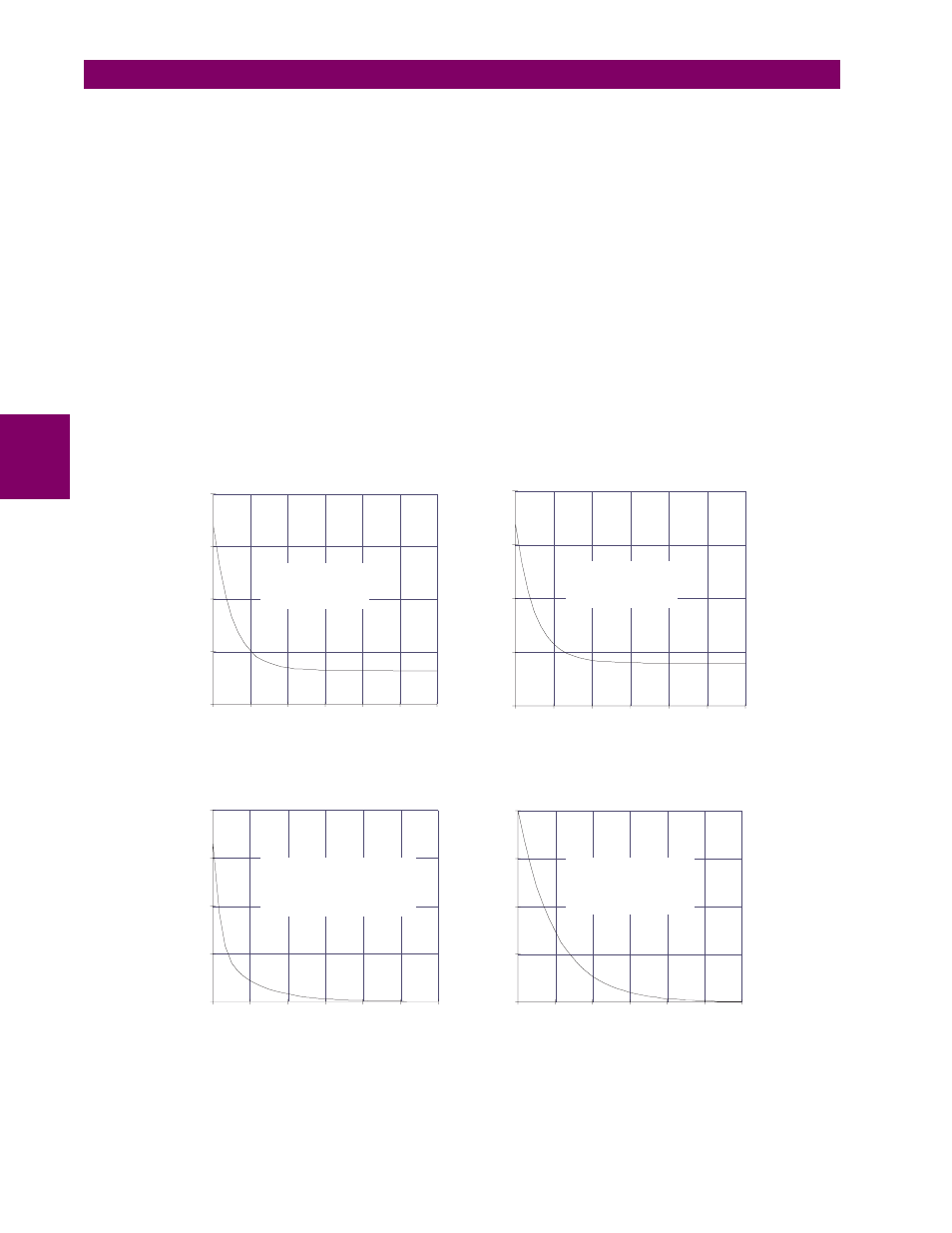

Figure 4–17: THERMAL MODEL COOLING

TC

used

TC

used_start

TC

used_end

–

(

) e

t

τ

⁄

–

(

) TC

used_end

+

=

TC

used_end

I

eq

overload_pickup

-------------------------------------------

⎝

⎠

⎛

⎞ 1 hot

cold

-----------

–

⎝

⎠

⎛

⎞ 100%

×

=

808705A1.CDR

0

25

50

75

100

0

30

60

90

120

150

180

Time in Minutes

T

h

er

m

a

l

Ca

p

a

ci

ty

U

s

ed

Cool Time Constant= 15 min

TCused_start= 85%

Hot/Cold Ratio= 80%

Ieq/Overload Pickup= 100%

0

25

50

75

100

0

30

60

90

120

150

180

Time in Minutes

T

h

er

m

a

l

Ca

p

a

ci

ty

U

s

ed

Cool Time Constant= 15 min

TCused_start= 85%

Hot/Cold Ratio= 80%

Ieq/Overload Pickup= 80%

0

25

50

75

100

0

30

60

90

120

150

180

Time in Minutes

T

h

er

m

a

l

Ca

p

a

ci

ty

U

s

ed

Cool Time Constant= 30 min

TCused_start= 85%

Hot/Cold Ratio= 80%

Motor Stopped after running Rated Load

TCused_end= 0%

0

25

50

75

100

0

30

60

90

120

150

180

Time in Minutes

T

h

er

m

a

l

Ca

p

a

ci

ty

U

s

ed

Cool Time Constant= 30 min

TCused_start= 100%

Hot/Cold Ratio= 80%

Motor Stopped after Overload Trip

TCused_end= 0%

MOTOR TRIPPED

100% LOAD

MOTOR STOPPED

80% LOAD