Dunkirk Excelsior EXB Series User Manual

Page 32

32

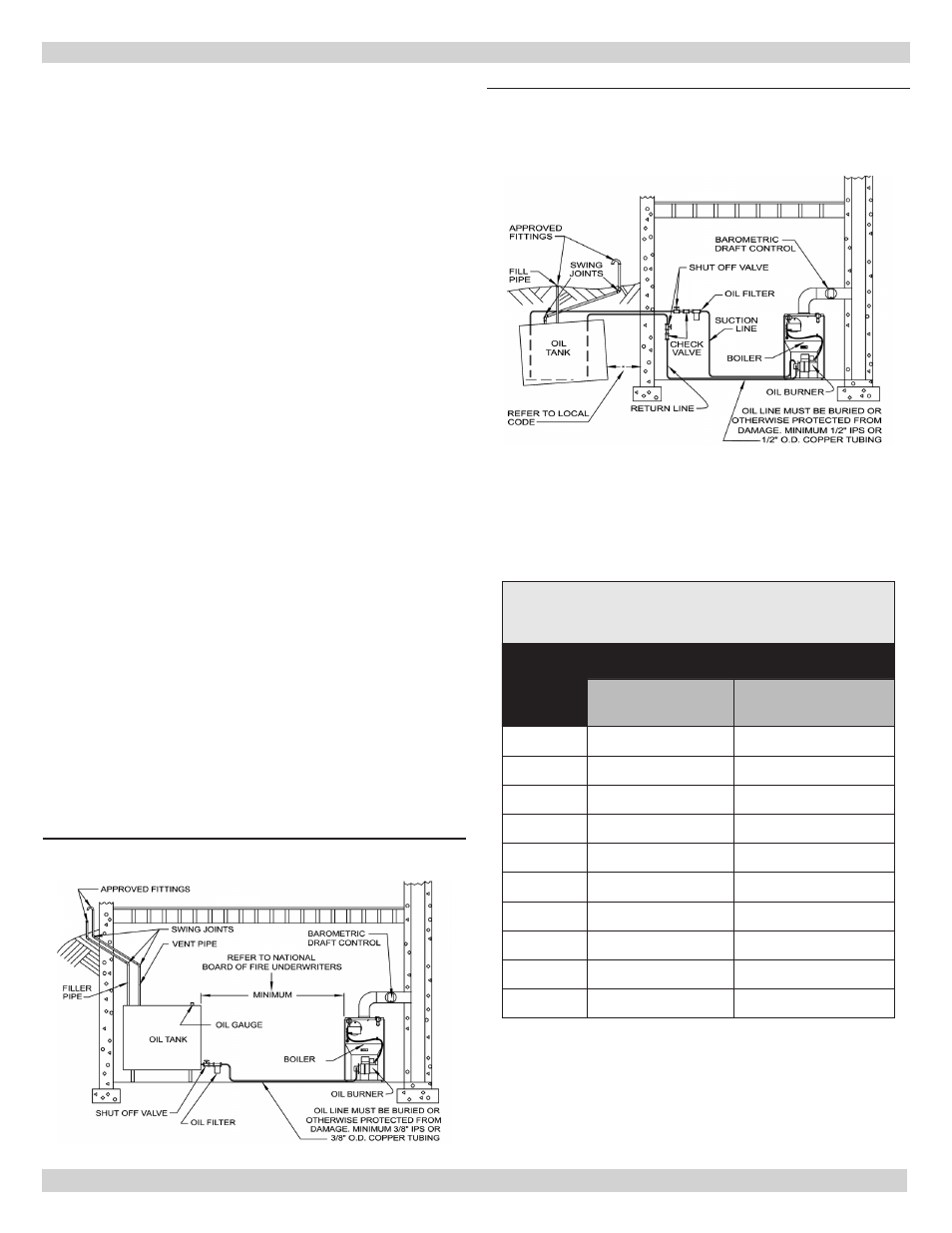

Figure 29 - Single Pipe Oil Line

Figure 30 - Double Pipe Oil Line

11 - FUEL SUPPLY PIPING

11.1 Installation of oil tank and piping shall conform

to requirements of authority having jurisdiction or in

absence of such requirements National Board of Fire

Underwriters . In addition, refer to NFPA 31 (U.S.) or

CSA B139 (Canada)

Installation of oil storage tank, vent, fill pipe and

caps shall conform to requirements of authority

having jurisdiction.

• In no case should vent pipe be smaller than 1¼" I.P.S.

• Fill pipe should not be less than 2" I.P.S.

• Suction line from tank to burner should be one

continuous piece of tubing to prevent air entering line

• Suction line, must be ⅜" O.D. copper tubing for runs of

50 feet or less, and ½" O.D. for longer runs.

• Use oil return line, same size as the suction line, on

installations where bottom of tank is below fuel unit of

burner.

• Bury oil lines or protect from mechanical injury.

• Flare fittings on all oil lines are required. Compression

fittings on suction line often allow air to be drawn into

fuel pump, making it difficult to maintain oil pressure at

nozzle.

• Do not run overhead fuel lines from tank to oil burner.

• Follow instructions, attached to fuel pump, for fuel pump

and by-pass connections.

• Install two stage fuel unit if tank is more than 20' from

boiler in place of single stage pump supplied as standard

equipment with burner. Verify rotation and speed are

identical and pump is suitable for burner horsepower

rating.

• Install oil line filter and shut-off valve in suction line.

• Install Shut-off valves in both suction and return lines at

burner for convenience in servicing burner.

• Allow extra tubing at burner so burner may be removed

from boiler for cleaning without disconnecting tubing.

See Figure 29 and 29.

• Use flexible oil lines so burner swing door can be opened

without disconnecting oil supply piping.

Table 5 - TWO STAGE UNITS,

TWO PIPE SYSTEMS (SEE FIGURE 15)

LIFT

“H”

Maximum Length of Tubing “R”

3/8” O.D.

Tubing (3 GPH)

1/2” O.D.

Tubing (3 GPH)

0

93 FT.

100 FT.

2

85 FT.

100 FT.

4

77 FT.

100 FT.

6

69 FT.

100 FT.

8

60 FT.

100 FT.

10

52 FT.

100 FT.

12

44 FT.

100 FT.

14

36 FT.

100 FT.

16

27 FT.

100 FT.

18

---

76 FT.