Warning – Dunkirk Excelsior EXB Series User Manual

Page 14

14

NOTICE

Do not install valve between boiler and controls

manifold or relief valve.

11.

Locate cast 1 1/4 x 1 1/4 x 3/4 tee and assemble on

long female adapter with 3/4” tapping facing toward

front of boiler and joint is water tight.

12.

Install Limit control mounting plug in upper 3/4”NPT

port facing front.

13.

Install Limit control & harness assembly. Loosen

mounting screw on bottom of limit control.

A. Mount control on mounting plug and tighten screw

to secure control. See Figure 7.

B. Confirm thermal limit/LWCO sensor bulb is fully

inserted to bottom of control well in top of rear

boiler section and secured with grommet. See

Figure 8.

C. Route thermal limit/LWCO sensor wire to control

and connect. See Figure 10, Page 15 and Figure 15,

Page 17.

Figure 7 - Control On Mounting Plug w/Screw

WARNING

Burn and scald hazard. Relief valve could

discharge steam or hot water during operation.

Check local codes for maximum distance from floor

or allowable safe point of discharge. Installation of

relief valve shall be consistent with ANSI/ASME Boiler

and Pressure Vessel Code, Section IV.

!

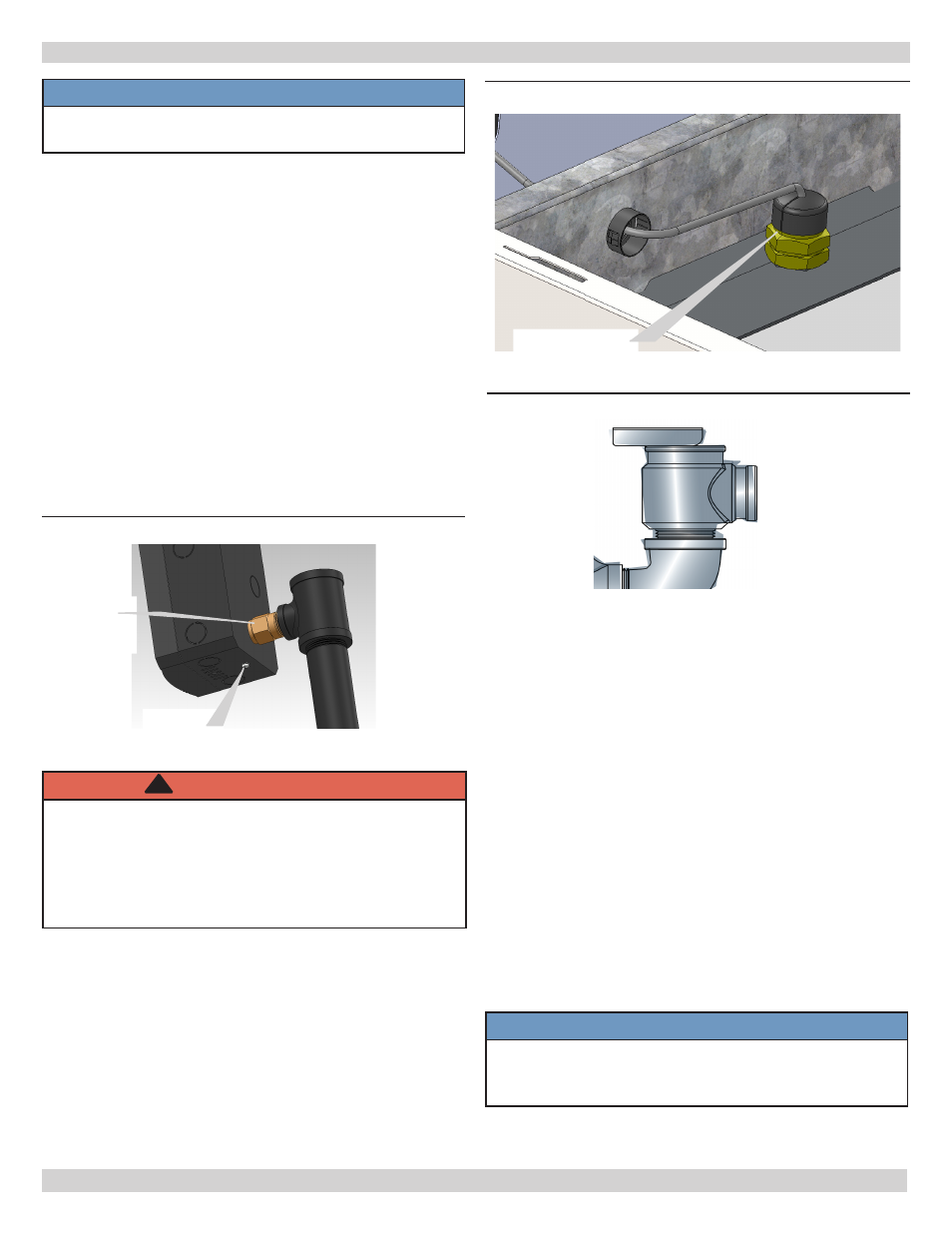

14.

Install Relief Valve. See Figure 9.

A. DO NOT pipe in area where freezing can occur. DO

NOT install shutoff valves, plugs or caps.

B. Locate 3/4”NPT x 90° street elbow. Install elbow using

3/4” NPT tapping in supply piping. Install elbow with

outlet facing directly up. Install relief valve with outlet

facing horizontally.

C. Pipe discharge of relief valve. Installation of relief

valve must be consistent with ANSI/ASME Boiler and

Pressure Vessel Code, Section IV.

Figure 8 - Grommet

15.

Check installation of liners and baffles (Not all

models). See Table 4, Page 16.

A. Check oval (4 section only) or V-shaped (certain 5

section models and all 6 and 7 section models) liner.

See Figures 11 & 12. Liner should be flush with front

edge of heat exchanger fins.

B. Flue way baffles (4, 5, 6 section only) are factory

installed in 3rd pass. Insure baffles are inserted in flue

way such that position tab touches casting between

2nd and 3rd Pass flue way. See Figure 13, Page 16.

Efficiency of boiler is based on insertion of flue way baffles

in 4, 5 and 6 section units. Baffles will generate lower gross

stack temperatures entering chimney. This has the potential

under certain operating conditions to cool flue gases below

dew point, creating condensation on interior chimney and

chimney connector surfaces. Remove baffles to increase

stack temperature if there are any signs of condensation in

chimney or chimney connector. Removing baffles alone may

not address condensation depending on other boiler and

heating system operating conditions.

NOTICE

Flue gas condensate is corrosive, which requires

special consideration and must be addressed

immediately.

8 - BOILER ASSEMBLY

TIGHTEN

SCREW

MOUNTING

PLUG

SENSOR IN WELL

WITH GROMMET

Figure 9 - Relief Valve