Carburetor adjustments, A, warning, Important – Troy-Bilt 8 HP User Manual

Page 57: A warning, 7 hp briggs & stratton, 8 hp kohler, Warning, Maimtikaice and service

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Carburetor adjustments

The carburetor provides the en

gine’s com bustion cham ber w ith

the correct air-fuel ratio for a w ide

range of operating conditions.

The factory settings should be

correct for average operating condi

tions and you should avoid m aking

unnecessary adjustm ents. H ow

ever, if you feel that an adjustm ent

is needed to com pensate for differ

ences in fuel, tem perature, altitude

or load, please refer to the follow

ing recom m ended adjustm ents.

A,

WARNING

K eep cigarettes, sparks, and open

flam es aw ay from the carburetor

and fuel system to prevent the pos

sibility of a fire or explosion.

IMPORTANT

The carburetor adjusting screw s

are needle valves w hich taper to

critical dim ensions. These screw s

can be dam aged if they are turned

in forcefully.

A

WARNING

D o not operate the engine in an

enclosed or poorly ventilated area.

E ngine exhaust gases contain car

bon m onoxide, an odorless, taste

less, and deadly poison.

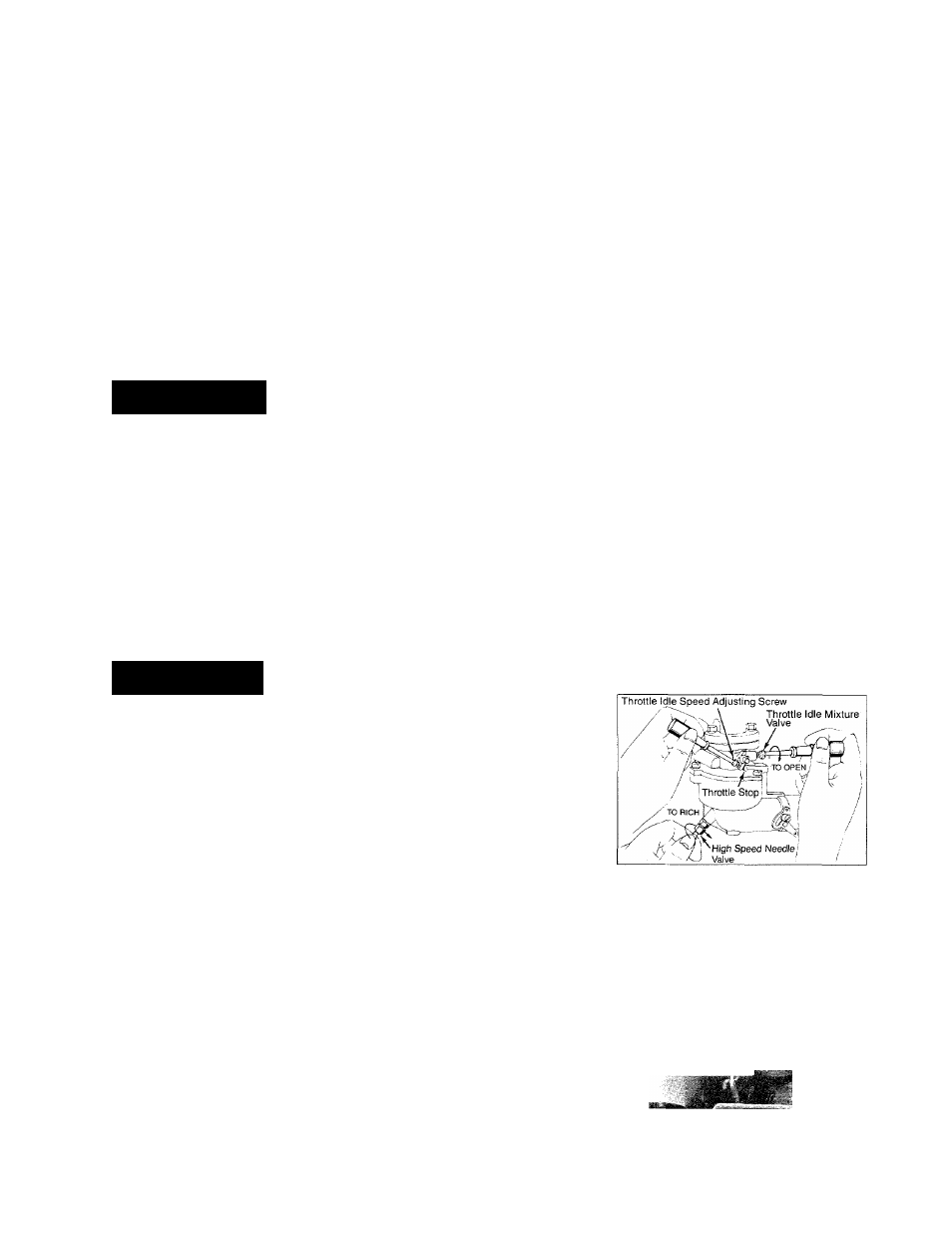

7 HP Briggs & Stratton:

1. W ith the engine stopped, gently

turn the H igh S peed N eedle Valve

and Throttle Idle M ixture V alve

clockw ise until they just close.

The valves m ay be dam aged by

turning them too far. See Figure

6-61.

2. N ow open H igh Speed N eedle

V alve IV

2

turns counterclockw ise

and Throttle Idle M ixture V alve one

turn counterclockw ise. This initial

adjustm ent w ill perm it the engine

to be started.

3. S tart engine and allow to w arm

for a few m inutes prior to final

adjustm ent. N O TE : The air cleaner

m ust be assem bled to carburetor

w hen running the engine.

4.

P lace the throttle lever on the

handlebar in the “FA S T” position.

Turn the H igh S peed N eedle V alve

clockw ise until engine slow s (lean

m ixture). Then turn it out past the

sm ooth operation point (rich m ix

ture). N ow turn the needle valve to

a m idpoint setting betw een rich

and lean.

5. A djust the idle R P M as follow s;

(a) R otate the throttle counter

clockw ise and hold it against

the Throttle S top w hile adjust

ing the Throttle Idle S peed

A djusting S crew to obtain 1750

R PM . Turn screw in for faster

idle; out for slow er idle.

(b) W hile still holding throttle

against Throttle Stop, turn

Throttle Idle M ixture V alve in

(lean) and out (rich). S et valve

at m idpoint betw een rich and

lean. R elease throttle. If engine

w ill not accelerate properly, the

carburetor should be read

justed, usually to a slightly

richer m ixture.

8 HP Kohler:

1

. W ith the engine stopped, turn

the M ain Fuel and Idle Fuel adjust

ing screw s clockw ise, until they

bottom lightly (P hoto 6-62).

2.

P relim inary S etting— M ain Fuel

S crew ; Turn the M ain Fuel S crew

out

2

full turns from bottom .

3. P relim inary S etting— Idle Fuel

S crew : Turn the Idle Fuel S crew

out 1V

4

turns from bottom .

4.

Final S etting— M ain Fuel S crew :

P lace the W heels/Tine/P TO D rive

Lever in “N EU TR A L” and start the

engine. Let it run at half-throttle

speed for 5-10 m inutes. M ove the

throttle lever to the “FA S T” posi

tion and then turn the M ain Fuel

S crew clockw ise until the engine

starts to lose speed (too lean a

m ixture). N ow , count the turns as

you turn the screw counterclock

w ise until the engine begins to run

unevenly (too rich a m ixture). Turn

the screw clockw ise to a point m id

w ay betw een the too lean and too

rich m ixtures. That position, or

turning the screw counterclock

MAIMTIKAICE AND SERVICE

w ise about V

2

turn m ore, should be

the proper setting for tilling.

5. Final S etting— Idle Fuel S crew :

P lace the W heels/Tine/P TO D rive

Lever in “N EU TR A L” and start the

engine. Let it run at half-throttle

speed for 5-10 m inutes. A llow the

engine speed to fall to idle, or put

the engine throttle in the idle posi

tion. A djust the Idle Fuel S crew by

follow ing the sam e procedure de

scribed in S tep 4. The recom

m ended idle speed should not

exceed 1500 R PM (R evolutions P er

M inute)f

6. Idle S peed Setting: Place

the W heels/Tine/P TO D rive Lever

in “N EU TR A L” and start the engine.

Let it run at half-throttle for 5-10

m inutes. A llow the engine speed to

fall to idle, or put the engine throt

tle in the idle position. A djust the

engine idle speed to the desired

R PM * by turning the Idle S peed

S crew clockw ise or counter

clockw ise. A llow several seconds

betw een each adjustm ent for the

engine to adapt to each new setting.

‘Typical idle speed is 1200 R PM .

6-61: 7 HP Briggs & Stratton Engine

carburetor.

'V

(

iti .

M A IN FU EL

ID LE S PE E D H

ID LE FU E L.

6-62: 8 HP Kohler Engine carburetor

(air cleaner components removed for

photo clarity).

55