Removing the wheels, A warning, Engine oil maintenance – Troy-Bilt 8 HP User Manual

Page 52: Tire and wheel maintenance, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Tire and wheel maintenance

The air pressure in the tires

should be checked after every 30

operating hours. The recom

m ended air pressure for tilling is

10 to 20 psi (pounds per square

inch).

U se a pocket-type tire gauge to

ensure that both tires are equally

inflated. If the air pressures are not

equal, it can cause the tiller to pull

to one side.

K eep the tires free of gasoline or

011

w hich can destroy the rubber.

N O TE: W hen installing bar tread

tires, m ake sure that the “V ”

shaped treads are facing forw ard,

in the direction of the engine.

Removing the wheels

A

WARNING

To help avoid personal injury, stop

the engine, rem ove the electric

start key, disconnect the spark

plug w ire, and let the engine and

m uffler cool before rem oving or

replacing the w heels.

E ach w heel is held in place by a

roll (spirol) pin that secures the

w heel hub to the w heel shaft. S im

ply drive out the roll pin to rem ove

a w heel, as explained below .

1. U sing a sturdy block, prop up

the transm ission until the w heels

are an inch or tw o off the ground.

2. To prevent the w heels from turn

ing, place the W heel Speed Lever

in either the “S LO W ” or “FA S T”

w heel speed gear.

3. U se either a 3/16-inch tapered

drift pin, a 1/4-inch untapered drift

pin, ora 16-penny(16d) nail w ith

a blunted point, to drive the roll pin

dow n through the w heel hub

(P hoto 6-46).

A

WARNING

W ear safety goggles to protect

your eyes from the possibility of

flying m etal fragm ents w hen driv

ing the roll pin into or out of the

w heel hub.

4.

If the w heel doesn’t slide easily

off the shaft, squirt som e penetrat

ing oil around the shaft and w heel

hub and tap the tire to set up vibra

tions w hich w ill help to distribute

the oil. B e patient and allow suffi

cient tim e for the oil to soak in.

5. B efore installing the w heel, ap

ply a thin coating of grease to the

w heel shaft. Then, install the

w heel and align the roll pin holes

by inserting your drift pin or nail

from underneath (P hoto 6-47). U se

a ham m er to tap in the roll pin

flush w ith the w heel hub.

N O TE: If a roll pin is loose, you can

hold it in place w ith an autom otive

engine hose clam p.

Engine oil maintenance

It is vitally im portant that you use

m otor oil of the proper service

grade and viscosity, and that you

regularly check and change the oil

according to the recom m ended

hours of operation. Incorrect, insuf

ficient, or dirty oil w ill cause pre

m ature engine w ear and dam age.

C heck the oil level each tim e

before starting the engine and

after each 5 hours of continuous

operation.

C hange the oil after the first 5

hours of new engine operation.

Thereafter, change the oil after

each 10 operating hours, or m ore

often if operated in extrem ely

dusty or dirty conditions.

N O TE: The engine m anufacturer

recom m ends oil changes after

each 25 operating hours. H ow ever,

please rem em ber that your tiller

w ill nearly alw ays be operating in

dusty or dirty conditions, w hich is

w hy w e recom m end a 10-hour

service schedule.

U se a clean, high-quality deter

gent m otor oil. The oil should be

rated w ith an S F or SG service

classification (look for those

letters on the container).

The oil sum p capacity for the

B riggs & S tratton engine is approx

im ately 2% pints; how ever alw ays

add enough oil so that it is to the

point of overflow in the oil filler

tube. For the K ohler E ngine the

capacity is approxim ately 32

ounces; how ever alw ays fill to the

“FU LL” m ark on the dipstick.

A lw ays use the correct viscosity

according to the air tem perature at

the tim e of operation (see chart

that follow s).

A

WARNING

To help avoid personal injury, stop

the engine, rem ove the electric

start key, disconnect the spark

plug w ire, and let the engine and

m uffler cool before checking, add

ing, or changing engine oil.

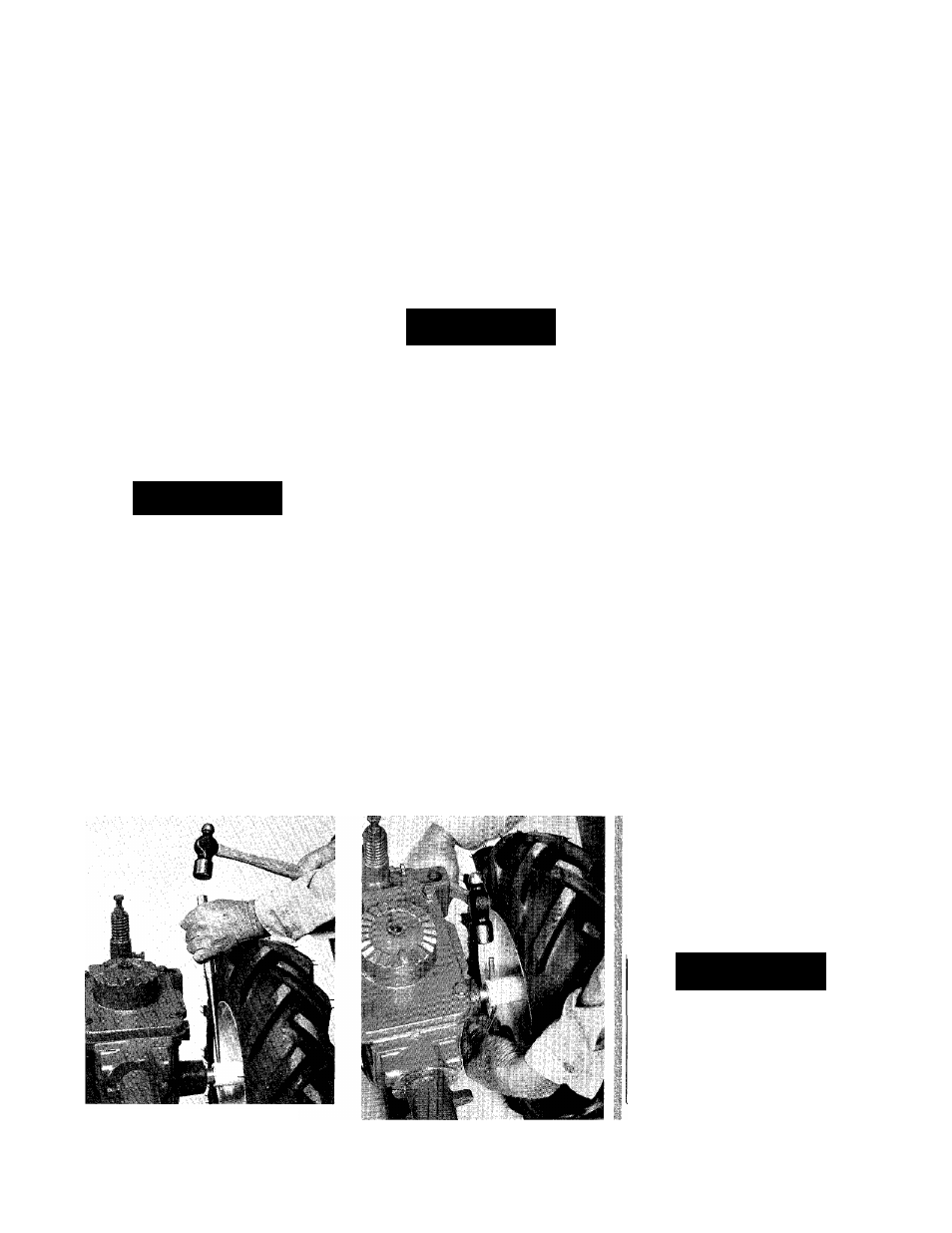

6-46: Drive roll pin out to remove

wheel.

6-47; Align holes and tap in roll pin.

50