B. checking gear oil levels – Troy-Bilt 8 HP User Manual

Page 41

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE AND SERVICE

amounts of oil to seep out, thus

relieving any excess pressure in

side the transmission. You should

not be concerned if you see oil

leaking from the twooil relief vents.

If you discover an oil leak, please

call or write our Technical Service

Department for parts and service

advice. (Be sure to ask about the

inexpensive seal drivers that are

available for the wheel shaft and

tine shaft oil seals.)

B. Checking gear oil levels

At every 30 hours of operation

you should check the levels of the

gear oil in the power unit and the

tine attachment transmissions.

Serious damage can result if the

transmissions are allowed to run

for even a short time without the

proper amount of oil.

The transmissions should be

cool when checking the oil levels

as the oil can expand if hot and

thus give a false reading. Also, the

power unit and tine attachment

must be connected when checking

(or adding) gear oil.

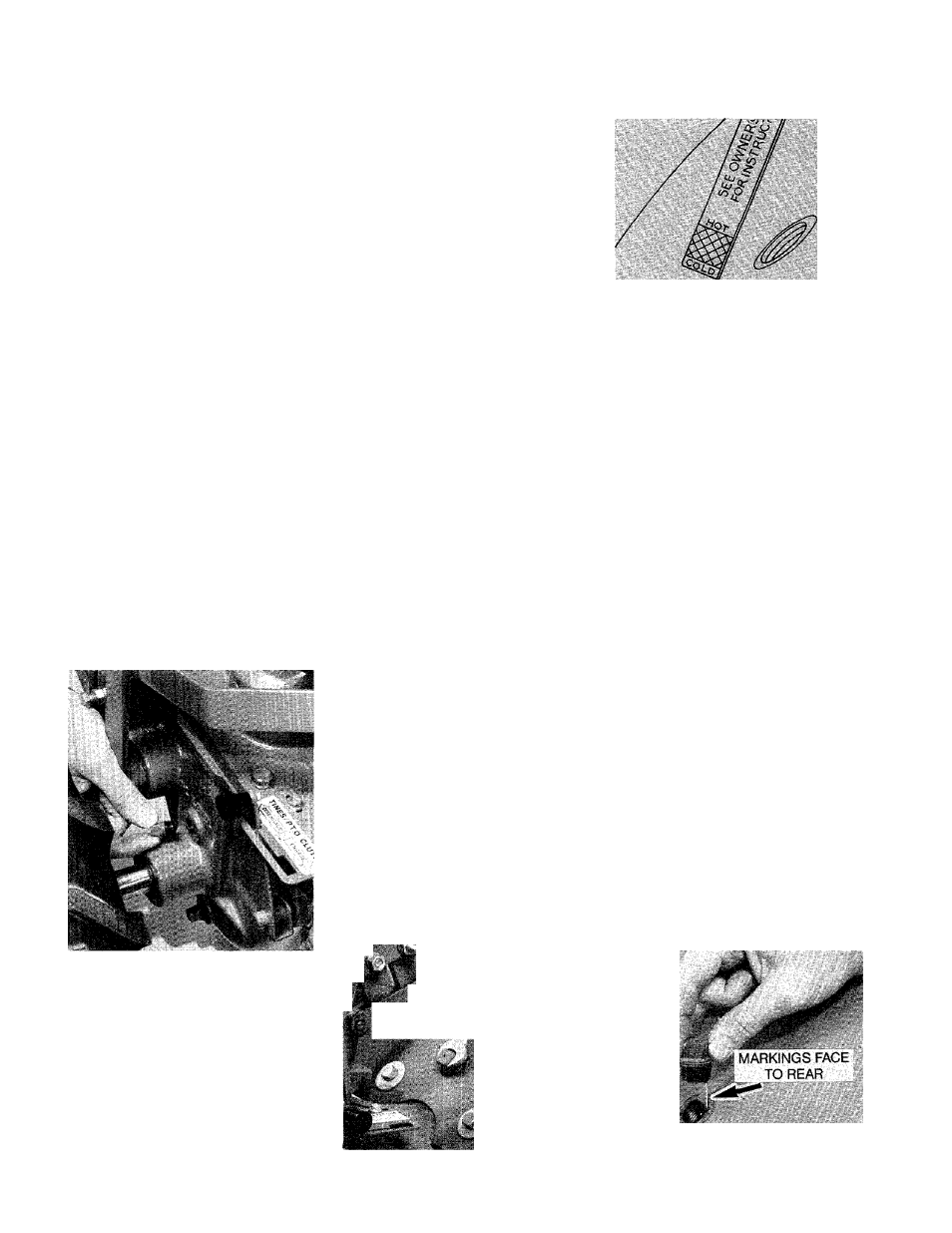

6-6: Remove oil level check plug.

To check the Power Unit oil level:

1. Make sure the tiller is on level

ground. Pull the Depth Regulator

Lever up until the tines are resting

on the ground.

2. Use a %-inch wrench to remove

the oil level check plug that is

located above the wheel shaft on

the left side of the transmission

(Photo 6-6).

3. If the oil level is correct, oil

should begin to seep out of the

hole as you remove the plug (be

patient in cold weather as the oil

may flow very slowly). If it does,

your check is finished and you

should securely replace the plug.

If there is no sign of oil, see the

“Adding Gear Oil” instructions

that follow these oil level check

ing procedures.

To check the Tine Attachment oil

level:

1. Make sure the tiller is on level

ground.

2. If the tiller has been operated

for 30 minutes or more within the

last hour, move the Depth Regula

tor Lever all the way down until it is

engaged in its highest notch. This

places the transmission in the cor

rect position to take a “Hot” oil >

level reading.

J)4n^

If the tiller has not beenopef^

ated within the last two hours, you

should also place the Depth Regu

lator Lever in its highest notch.

Then, prop up the drag bar (located

below the tines) approximately 3%

inches off the ground (using a 2 " x

4 " board on edge works well). This

places the transmission in the

correct position to take a “Cold”

oil level reading.

3. Allow the tiller to rest in this

position for at least five minutes

for a “Hot” reading or two hours

for a “Cold” reading. (Allow more

time if the air temperature is

below 40 °F).

4. Clean the area around the tine

attachment dipstick so that no de

bris will fall into the transmission.

m

6-8: Tine attachment dipstick

markings.

5. Using a 9/16-inch wrench, re

move the dipstick as shown in

Photo 6-7. Wipe the dipstick with a

clean rag and note the “Hot” and

“Cold” range markings on one side

(Figure 6-8).

6. With the markings facing to the

rear of the tiller, gently lower the

dipstick straight down into the

sump hole until the end just tou

ches the drive shaft inside the hole

(Photo 6-9). Do not force, or try to

thread the dipstick into the hole.

Doing so will bend the dipstick and

result in an incorrect reading.

7. After a few seconds, carefully

remove the dipstick and look at

the markings. If taking a “Hot”

reading, the oil level should be

within, or slightly above, the “Hot”

range marking (checkered pat

tern). If taking a “Cold” reading,

the oil level should be within, or

slightly above, the “Cold” range

marking.

8. If the oil level is okay, your

check is finished and you should

securely replace the dipstick. If

the oil level is low, see the instruc

tions that follow.

' ’’I'l

‘ s ^

6-7: Remove tine attachment dipstick. 6-9: Insert dipstick straight down.

OQ