How to adjust belt tension – Troy-Bilt 8 HP User Manual

Page 44

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

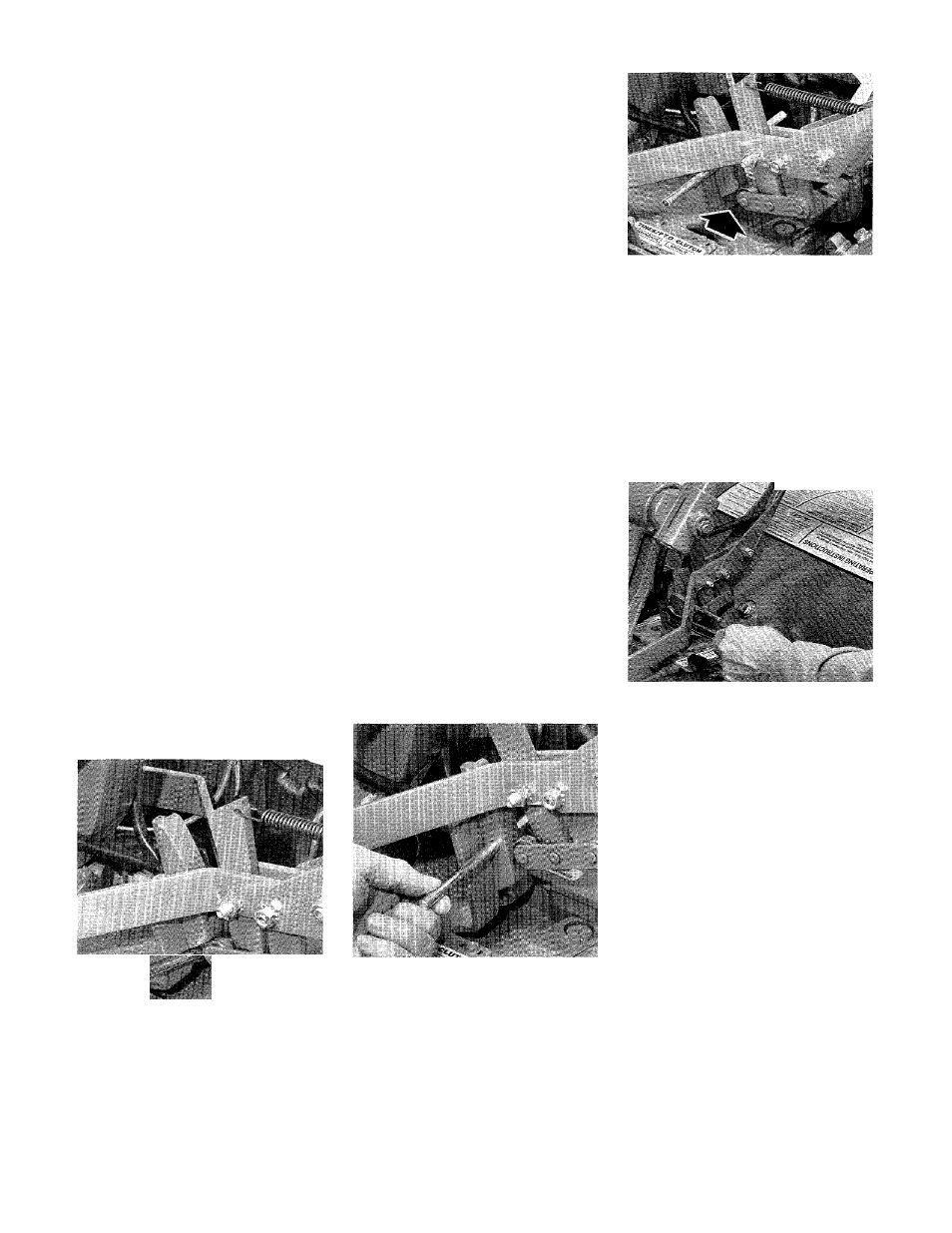

3. The belt tension is correct if the

front of the clutch roller is 1/4 to

5/16-inches away from the face of

the upright bracket that holds the

adjustment block in place (Photo

6-14). To measure this distance:

(a) Without moving the clutch

roller, try to insert the V4-inch

thick, slotted end of the belt

adjustment tool in between the

roller and the bracket. The flat

edge of the tool must be facing

the roller. See Photo 6-15.

(b) If only the slotted end of the

tool will fit, the belt is properly

adjusted. This V4-inch gap is

ideal.

(c) If the slotted end will not fit, the

belt is too loose.

(d) If the full thickness (5/16-inch)

of the tool easily fits, the belt is

too tight.

4. If the belt tension is correct,

return the shift lever to the “NEU

TRAL” position and check the ten

sion again after the next 10 operat

ing hours. If the belt is too loose or

too tight, refer to the adjustment

instructions that follow.

How to adjust belt tension:

1. The tension on the drive belt is

adjusted by moving the belt adjust

ment block either down to tighten

the belt, or up to loosen the belt.

As a rule of thumb, the distance

the block moves will approximately

equal the distance the roller

moves. In most cases, the clutch

roller will not have been very far

out of position, and therefore only

a slight movement of the block will

be required.

2. Place the Wheels/Tines/PTO

Drive Lever in “NEUTRAL”. The

clutch roller will come to rest any

where on the face of the belt ad

justment block, depending upon

drive belt length and future adjust

ments for belt tension.

3. Insert the belt adjustment tool

through the hole in the side of the

adjustment block, spacing the

ends of the tool equally on both

sides (Photo 6-16). Rotate the tool

so that the slotted end is fac

ing down.

6-15: Insert slotted end of belt adjust

ment tool between roller and bracket,

with flat side of slot facing roller.

6-16: With shift lever in “NEUTRAL”,

insert tool through hole in adjustment

block.

4. Place the Wheels/Tines/PTO

Drive Lever in “FORWARD”. The

arms of the clutch control yoke will

be resting on the belt adjustment

tool and the clutch roller should be

engaged slightly beneath the ad

justment block (Photo 6-17).

6-17: With shift lever in “FORWARD”,

clutch roller should be engaged

slightly beneath adjustment block.

5. Use one hand to hold the drive

lever in “FORWARD” while using a

9/16-inch wrench to loosen (do

not remove) the bolt in the back of

the belt adjustment block (Photo

6-18).

6-18: Hold lever while loosening bolt.

Push lever down to tighten belt or pull

up to loosen belt.

6. Push the drive lever down if the

belt needs tightening, or pull the

lever up if the belt needs loosen

ing. The adjustment block should

move freely in either direction. Hold

the drive lever in place and se

curely tighten the bolt in the adjust

ment block.

7. Let go of the drive lever and

remove the belt adjustment tool

from the hole in the adjustment

block.

8. Check the tension on the belt

by following the previous “How to

Measure Belt Tension” instructions.

NOTE: If the adjustment block has

moved all the way down in its

bracket and you still measure less

than ’/4-inch between the clutch

roller and the bracket, then the

belt has worn too much and a new

one is needed.

42