Tighten bolts and nuts, A warning, Important – Troy-Bilt 8 HP User Manual

Page 39

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Tighten bolts and nuts

MAIMTEMAMCE AND SERVICE

A

WARNING

To help avoid personal injury, stop

the engine, remove the eiectric start

key, disconnect the spark plug wire,

and iet the engine and muffler coo!

before inspecting or servicing the

tilier or engine.

It’s a good idea to check for

loose or missing bolts, nuts and

screws after every 10 operating

hours. Failure to tighten or replace

fasteners can result in poor per

formance, equipment damage, or

oil leaks. If you need to replace a

fastener, be sure to refer to your

Parts Catalog for the correct size

and for any special grade specifi

cation. Most fasteners are available

locally, or you can order directly

from our Parts Department.

Most bolts, nuts and screws on

your tiller are easily visible. Please

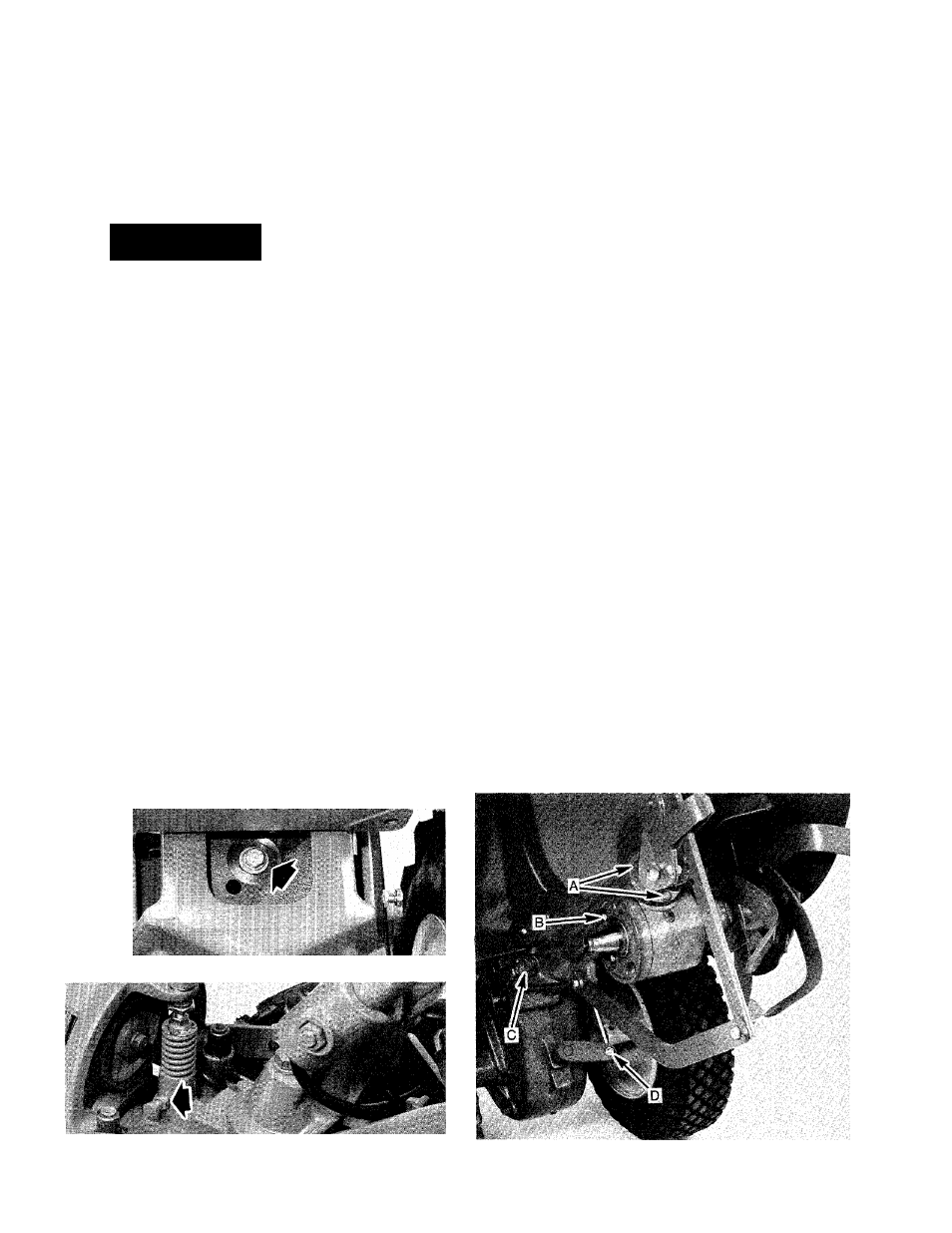

refer to Photos 6-1, 6-1A and 6-2

for the following fasteners that re

quire special attention.

1. Check transmission pulley

mounting bolt (Photo 6-1). If

washer behind bolt head is loose.

1

then bolt must be tightened se

curely. To tighten bolt, insert a

punch or thick screwdriver into the

hole next to the bolt and wedge

the tool against the side of the

motor mount casting. This will pre

vent the pulley from turning as you

tighten the bolt.

2. Check jam nut on left side of

neutral plunger assembly (Photo

6-1 A). If loose, place one wrench

on head of bolt and tighten jam nut

with second wrench.

3. Check the three rear bearing

cap screws that are located under

neath the depth regulator mount

ing bracket assembly (“A” in Photo

6-2). If these screws are loose it

could cause an oil leak or exces

sive end play in the drive shaft.

At.

Check the five bolts that fasten

the tiller housing cover to the left

side of the transmission (“B” in

Photo 6-2). If the bolts or cover are

loose, it could cause an oil leak. To

gain access to the housing cover,

you will have to remove the left

side tine holder. See “Bolo Tine

Maintenance” in this Section for

tine holder removal instructions.

5. Check the two swing-bolts that

connect the power unit transmis

sion to the tine attachment (“C” in

Photo 6-2). These bolts should be

checked after every

2

-V

2

hours of

operation. Failure to do so could

cause excessive wear to the locat

ing pin on the power unit, and

enlargement of the locating hole in

the tine attachment. The bolts must

be kept very tight. If you have a

torque wrench, tighten each to 70-

80 ft. lbs.

6. Check the locknut that fastens

the shifting linkage to the eccen

tric shifting lever (“D” in Photo

6-2). Do not tighten the locknut

against the eccentric lever. It

should be very close to, but not

touching the lever.

IMPORTANT

Screws or bolts that thread into

the transmission housing should

be coated w-th a non-hardening

gasket sealant (available at hard

ware or automotive supply storosi.

The sealant helps to prevent oil

from leaking past the threads.

6-1: Check bolt on transmission pulley.

6-1 A: Check jam nut on plunger assembly.

6-2: Gently tilt tiller forward to check these fasteners.

37