C. checking and adjusting reverse drive, To replace the reverse disc – Troy-Bilt 8 HP User Manual

Page 47

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

iAlCE

mo

SERVICE

/

■r

C. Checking and adjusting

reverse drive

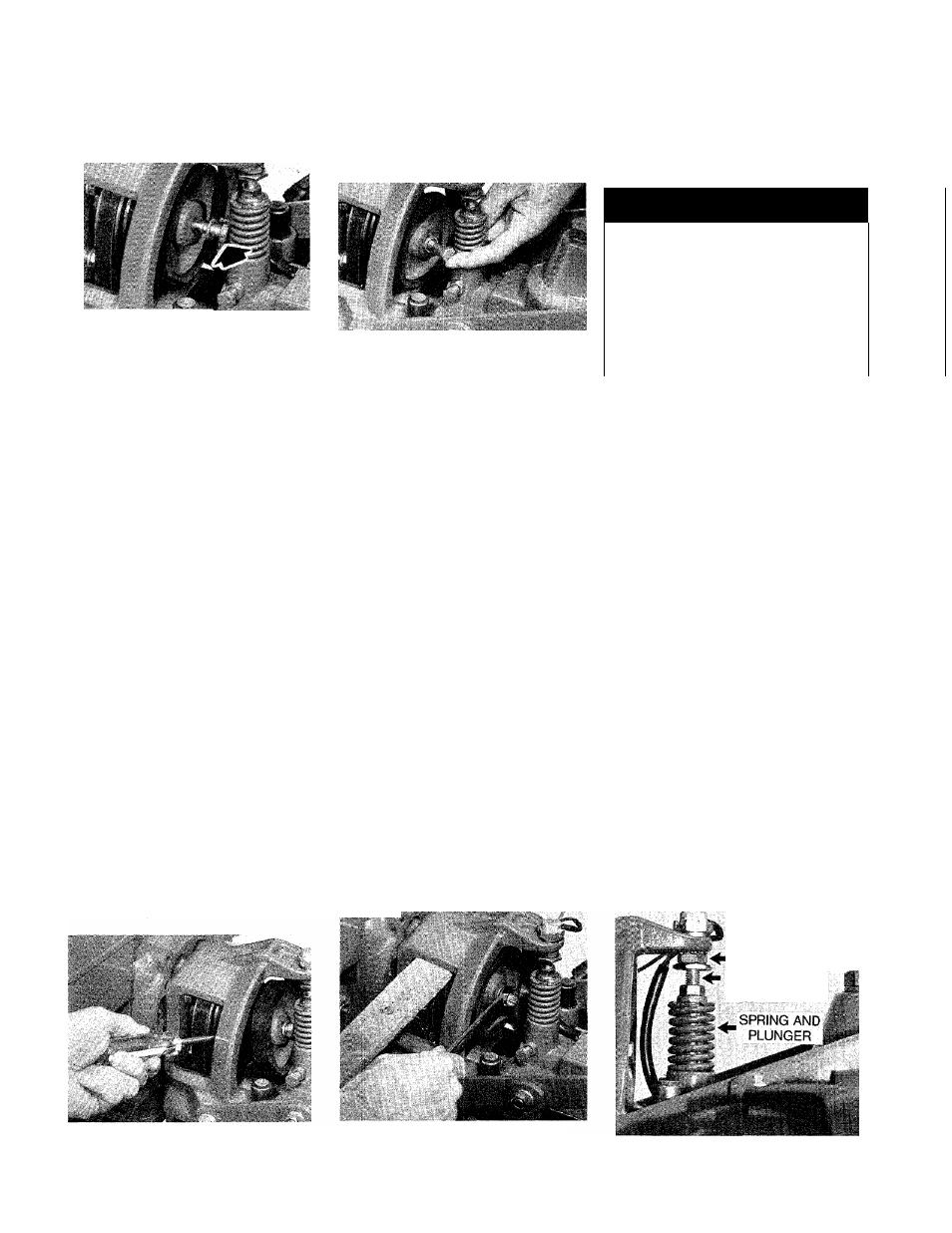

6-29: Loosen, but do not remove bolt.

2. To prevent the reverse disc and

its mounting bolt from turning as

you try to remove the bolt, first

place a 5/16-inch thick board be

tween the top of the engine pulley

(avoid the disc and drive belt) and

the cast iron engine mount (Photo

6-28).

3. Working from the left side of the

tiller, place the boxed end of a

9/16-inch wrench on the mounting

bolt. Then pull up hard on the stick

and push down sharply on the

wrench. This sharp push with the

wrench should break the bolt loose

without also causing the pulley

to turn.

4. Loosen the bolt until it just tou

ches the reverse spring and plunger

assembly (Photo 6-29). Don’t try to

remove the bolt just yet.

5. Use a screwdriver to separate

the disc from the engine pulley

(Photo 6-30).

6. Slide the disc out until it tou

ches the head of the mounting bolt.

Then angle the disc a little to the

left and remove the bolt and its

lockwasher (Photo 6-31). Now

remove the disc.

6-31: Angle disc to remove or install

mounting bolt.

To replace the reverse disc:

1. One side of the disc has a

raised shoulder in its center. When

installing the disc, this shoulder

must be facing away from the en

gine pulley.

2. With the Wheels/Tines/PTO

Drive Lever in “NEUTRAL”, insert

the disc in front of the engine pul

ley and angle it as shown in Photo

6-31. Put the lockwasher on the

bolt and insert the bolt through the

disc.

3. Hold the disc against the engine

pulley and hand-tighten the bolt as

far as you can.

4. To fully tighten the bolt, place

the 5/16-inch thick board in be

tween the top of the engine pulley

(avoid the disc and belt) and the

engine mount (Photo 6-32). Now

pull up hard on the board while

you tighten the bolt with the wrench.

5. Check for correct reverse drive

operation by referring to the fol

lowing instructions.

A WARNING

To help avoid personal injury, stop

the engine, remove the electric

start key, disconnect the spark

plug wire, and let the engine and

muffler cool before inspeoting or

adjusting the reverse drive

components.

When the Wheels/Tines/PTO

Drive Lever is shifted into

“REVERSE”, the engine and the

engine mount move down to press

on the reverse adjustment bolt

(Photo 6-33). This action com

presses the reverse spring and

plunger assembly, requiring you to

hold the lever up in “REVERSE”.

When you let go of the lever, the

spring automatically pushes the

lever back into “NEUTRAL”.

The spring and plunger assem

bly is designed to prevent the re

verse disc from making contact with

the transmission pulley until you

decide to shift into “REVERSE”.

When the lever is in “NEUTRAL”,

the switch body on the bottom of

the engine mount tab should be

resting squarely on top of the re

verse adjustment bolt (Photo 6-33).

The reverse adjustment bolt can

be adjusted up or down to correct

a number of reverse drive operat

ing problems, as explained next.

■ SWITCH BODY

ADJUSTMENT

BOLT

6-30: Use screwdriver to separate

disc from engine pulley.

6-32: Wedge pulley with board and

tighten bolt.

6-33: Spring and plunger assembly.

45