4 tiller installation, 5 tiller lubrication, 6 tine adjustment – Ariens 932 Series User Manual

Page 57: Tiller installation -5, Tiller lubrication -5, Tine adjustment -5, Attachments

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Attachments

9.4 Tiller Installation

Remove carriage bolt and lock nut that secures

chute crank to handlebar (on ST 2 + 2 cap

screws secure bracket to engine).

Remove belt guard and four cap screws secur

ing auger/impeller housing to frame. Tip unit

apart, remove attachment drive belt and

auger/impeller housing from frame.

Place attachment drive belt on tiller pulley.

With cap screws removed from Sno-Thro,

secure rotary tiller to frame. Install attachment

drive belt on engine pulley and check belt

alignment (move pulley on tiller in or out as

necessary to align).

9.5 Tiller Lubrication

A

CAUTION: DO NOT touch engine or tiller

drive parts which are hot from operation.

Check oil level every ten to fifteen hours of

operation or daily during hard use. Oil level

must be up to bottom of oil fill hole with tiller

level.

Drain and refill gear case seasonally. Use

Ariens L-2 Special Gear Lubricant (approx

imately 4 ounces). To drain, remove attach

ment from tractor, remove oil filler plug and tip

attachment forward.

1. Cap Screw

2. Oil Filler Plug

Figure 9-3: Tiller Lubrication

After draining, level tiller, fill gear case with oil,

and replace oil filler plug.

i

Once each season, remove cap screw from top

of gear case and apply a few drops of Ariens

Special Gear Lubricant through hole (this

lubricates drive shaft and rear bushing) and

replace cap screw. DO NOT over lubricate. Too

much oil on shaft will result in oil leaking out

of breather hole on side of gear case, which

may clog breather.

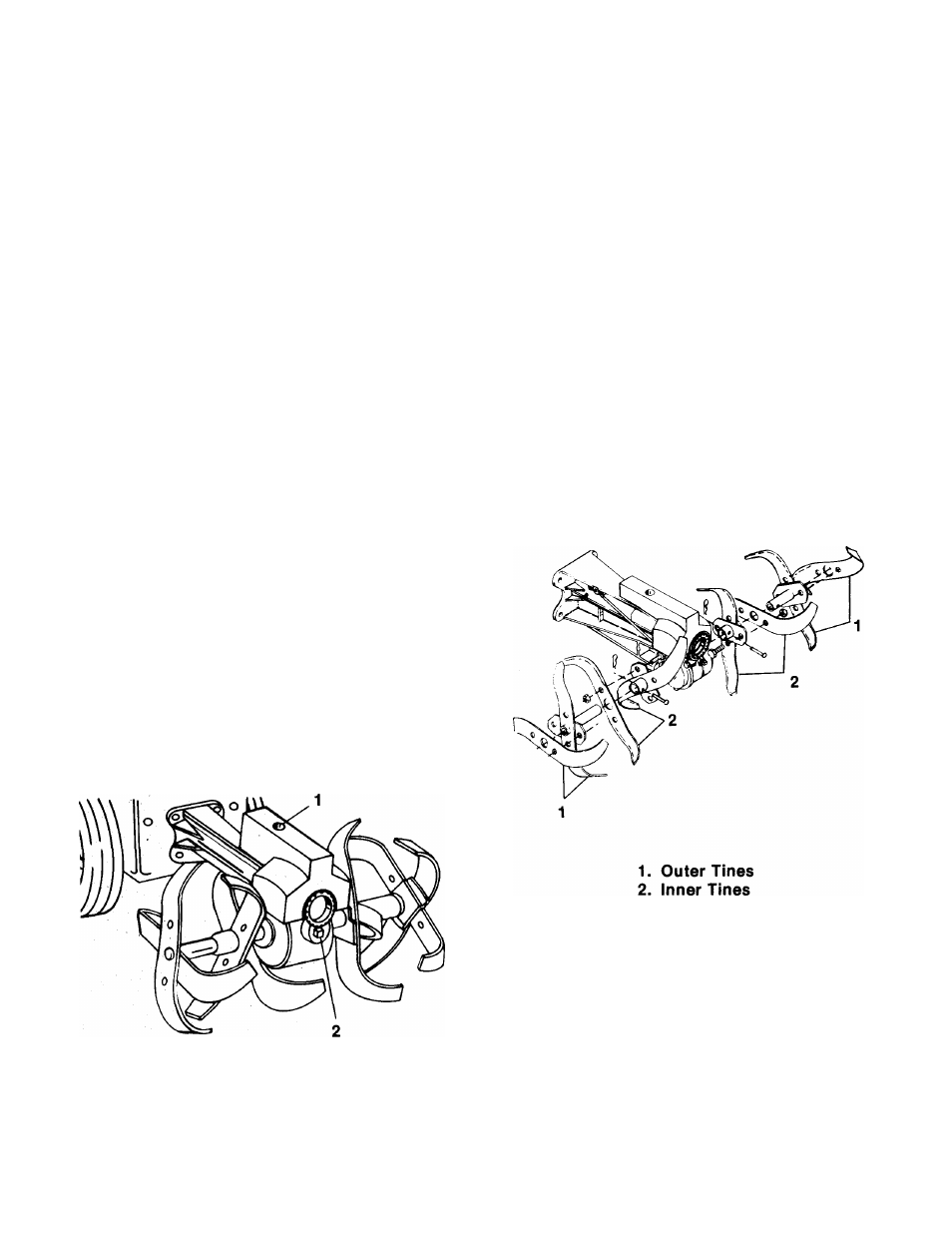

9.6 Tine Adjustment

Wheel width of Sno-Thro tractor is fixed,

therefore most tilling will be done with tines

set for maximum tilling width (20”). For

cultivating and working between bushes and

plants, tilling width of tines is adjustable from

7 to 20 inches in four stages.

i

Figure 9-4: Tine Adjustment

For maximum tilling width (20”) outer tines

face outward. For next widest tilling width,

outer tines are interchanged and tips face in

ward. Remove outer tines for next to narrowest

tilling width, and for narrowest tilling width

(7”), remove outer tines and face inner tines in

ward.

9-6