1 introduction, 2 auger/impeller housing, 3 auger/impeller removal – Ariens 932 Series User Manual

Page 38: 4 attachment clutch/impeller brake, 1 introduction -4, Auger/impeller housing -5, Auger/impeiler removal -5, Attachment clutch/impeller brake -5, Auger/impeller - discharge chute

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Auger/Impeller - Discharge Chute

6.1 Introduction

A

WARNING: Stop engine, remove key,

wait for moving parts to stop and remove

wire from spark plug before leaving

operator’s position and attempting to

maintain or inspect auger.

WARNING: Remove wire from spark plug

before attempting any repair or adjust

ment procedures.

When unit is tipped onto housing, remove

enough fuel so that no spillage will occur,

block securely and remove bottom cover.

A

WARNING: Gasoline is highiy flammabie

and its vapors are explosive. Handie with

care.

6.2 Auger/Impeller Housing

Remove nut and lockwashers holding worm

clevis to housing and position crank out of

way.

On auger propelled models, remove nut secur

ing chute bracket to engine/motor, and remove

chute.

On models with flat gear, remove hardware

securing chute bracket to engine and remove

hair pin securing chute rod to pinion gear.

Remove chute rod and lift discharge chute off

augeryimpeller housing.

Remove two screws securing belt guard to

tractor arid remove belt guard.

Remove top screws and loosen lower screws

that secure impeller housing to frame on each

side and tip tractor and impeller housing apart.

Assemble using reverse procedure.

6.3 Auger/Impeller Removal

Remove (3) nuts holding bearing flange to

housing on each side, remove cap screw,

lockwasher and washer on each side holding

auger shaft, and remove bearing flange with

bushing.

Remove pulley from auger/impeller assembly

and pull gear case and auger/impeller

assembly free of housing.

Remove shear bolts and remove augers from

shaft.

Check parts for wear or replacement.

Assemble using reverse procedure.

NOTE: Make sure pulleys align. If alignment is

necessary, loosen attachment pulley set

screws, reposition pulleys and tighten set

screws.

6.4 Attachment Clutch/Impeller Brake

A

WARNING: With improper use, injury

may result if attachment clutch lever is

released and brake DOES NOT STOP

auger/impeller within 5 seconds.

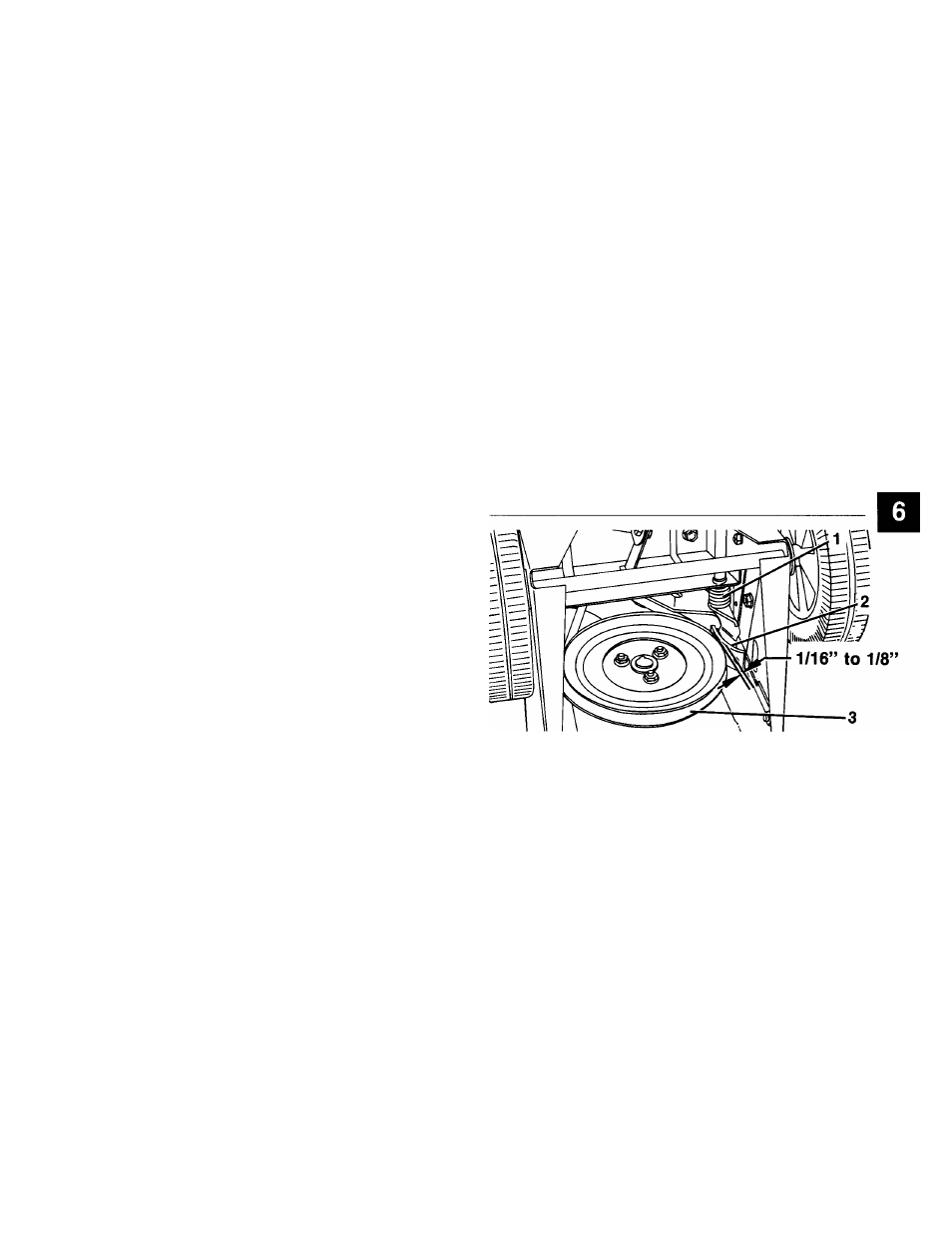

1. Spring Extension - 3/8”

2. Brake Shoe

3. Attachment Drive Belt

Figure 6-4: Attachment Clutch and Impeller

Brake

To check and/or adjust impeller brake, tip unit

forward onto auger/impeller housing. Remove

bottom cover by removing rear and loosening

front cap screws.

Measure distance between impeller brake

shoe and belt with attachment clutch engaged.

When attachment clutch is disengaged, brake

must contact belt.

If impeller brake shoe is not 1/16 to 1/8 inch

from belt, disengage clutch (release bail),

loosen attachment idler nut, reposition idler to

compensate for belt length, and tighten nut.

6-5