5 scraper blade, 6 auger rubber, Scraper blade -6 – Ariens 932 Series User Manual

Page 39: Auger rubber -6, Auger/impeller - discharge chute

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Auger/Impeller - Discharge Chute

Adjust attachment clutch cable with clutch

disengaged. Pull clutch chain taught and con

nect chain link to spring. Spring should extend

approximately 3/8” with clutch engaged. With

clutch disengaged, clutch arm should fall to its

maximum down position.

6.5 Scraper Blade

IMPORTANT: If blade wears too far, auger/im-

peller housing may be damaged.

Scraper blade on models with runners is ad

justable to compensate for wear.

To adjust scraper blade, tip unit back onto

handlebar, support housing, and loosen nuts

retaining blade. With runners adjusted to their

full up position, reposition scraper blade down,

flush with runners, and tighten lock nuts.

3 1

Shear Bolt

Scraper Blade

Auger

Figure 6-5: Shear Bolts and Scraper Blade

On 2 + 2 models, scraper blade is adjustable

to compensate for wear and to control traction.

Best operation occurs if scraper blade edge

leaves a fine dusting of snow with auger tracks

(auger propels unit). Adjust scraper blade

equally its full length if machine does not

scrape cleanly or if machine does not drive for

ward properly.

To adjust scraper blade, tip unit back and rest

unit on handlebar. Loosen nuts on carriage

bolts along scraper support. If unit does not

scrape cleanly, move scraper blade forward. If

unit does not drive forward and scraper blade

drags, move scraper blade to the rear.

NOTE: Be sure scraper support is fully engaged

in groove of scraper blade. Tighten hardware

and test unit. Repeat adjustment as required

until proper operation is obtained.

6.6 Auger Rubber

On 2 -I- 2 models, the rubber edges on auger

will wear and require replacement after a

period of use. Two replacement kits are

available.

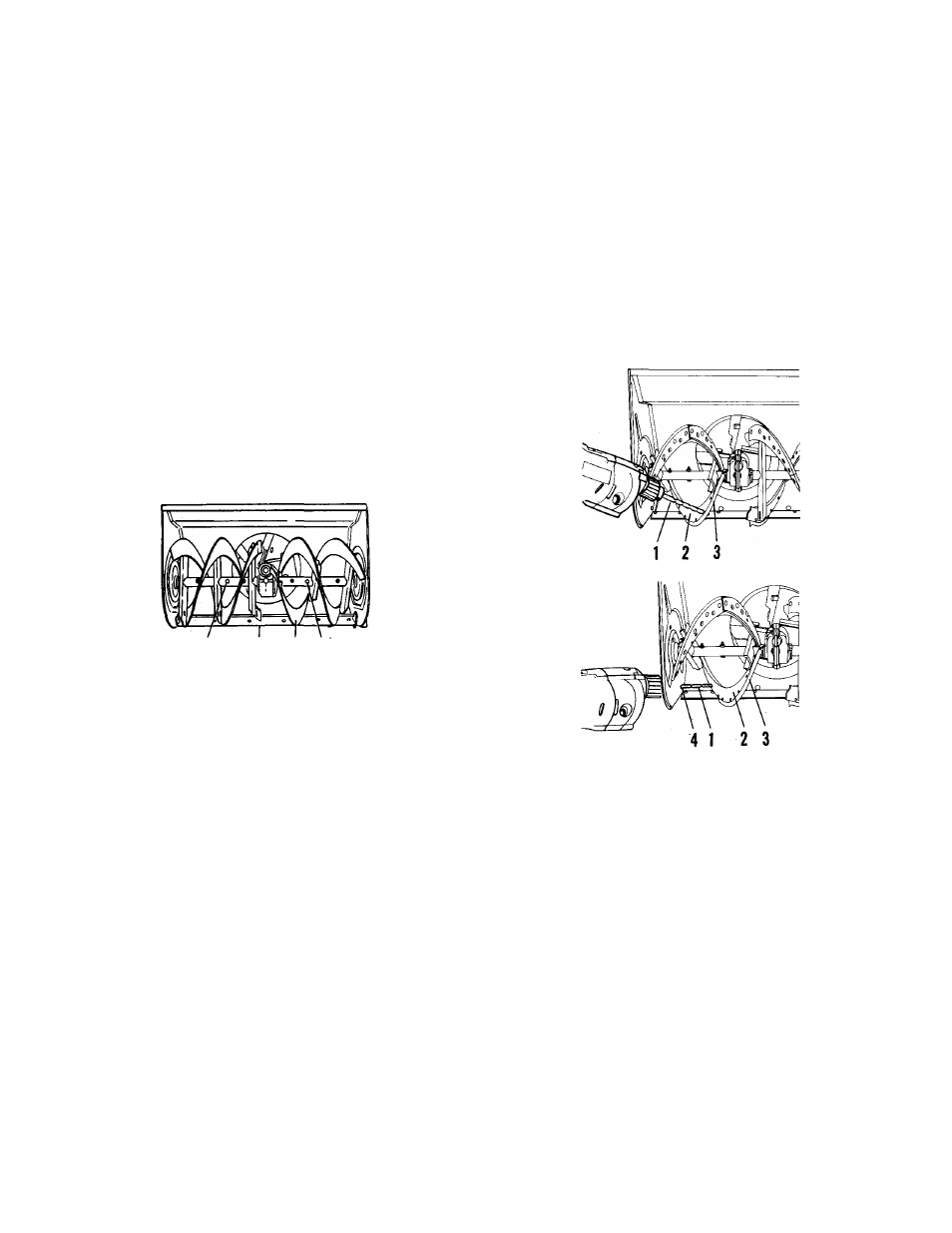

1. Drill

{V

a

”

or larger)

2. Auger

3. Rubber Edge

4. Access Hole

Figure 6-6: Auger Rubber Replacement

The second procedure replaces the rubber

edges and requires the drilling off of rivets

holding old rubber edge to segment by means

of a 1/4” diameter or larger drill bit. (An access

hole is provided on sides of auger/impeller

housing for access to outer rivets.) Then posi

tioning new rubber edge on segment and se

curing with bolts, flat washers and lock nuts.

The first procedure replaces both the right and

left augers requiring the removal of the augers

and impeller from the auger/impeller housing.

Then removing augers from auger shafts, plac

ing new augers onto auger shafts and reas

sembling unit.

I

NOTE: After repiacement of auger rubber

edges, adjust scraper biade per instruction in

Adjustments Section.

6-6