2 friction wheel removal, 3 drive plate removal, 2 friction wheei removal -4 – Ariens 932 Series User Manual

Page 31: 3 drive plate removal -4, Friction wheei drive, 1 introduction, 4 clutch fork removal

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Friction Wheei Drive

5.1 Introduction

A

WARNING: Remove wire from spark plug

before attempting any repair or adjust

ment procedures.

When unit is tipped onto housing, remove

enough fuel so that no spillage will occur,

block securely and remove bottom cover.

A

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

care.

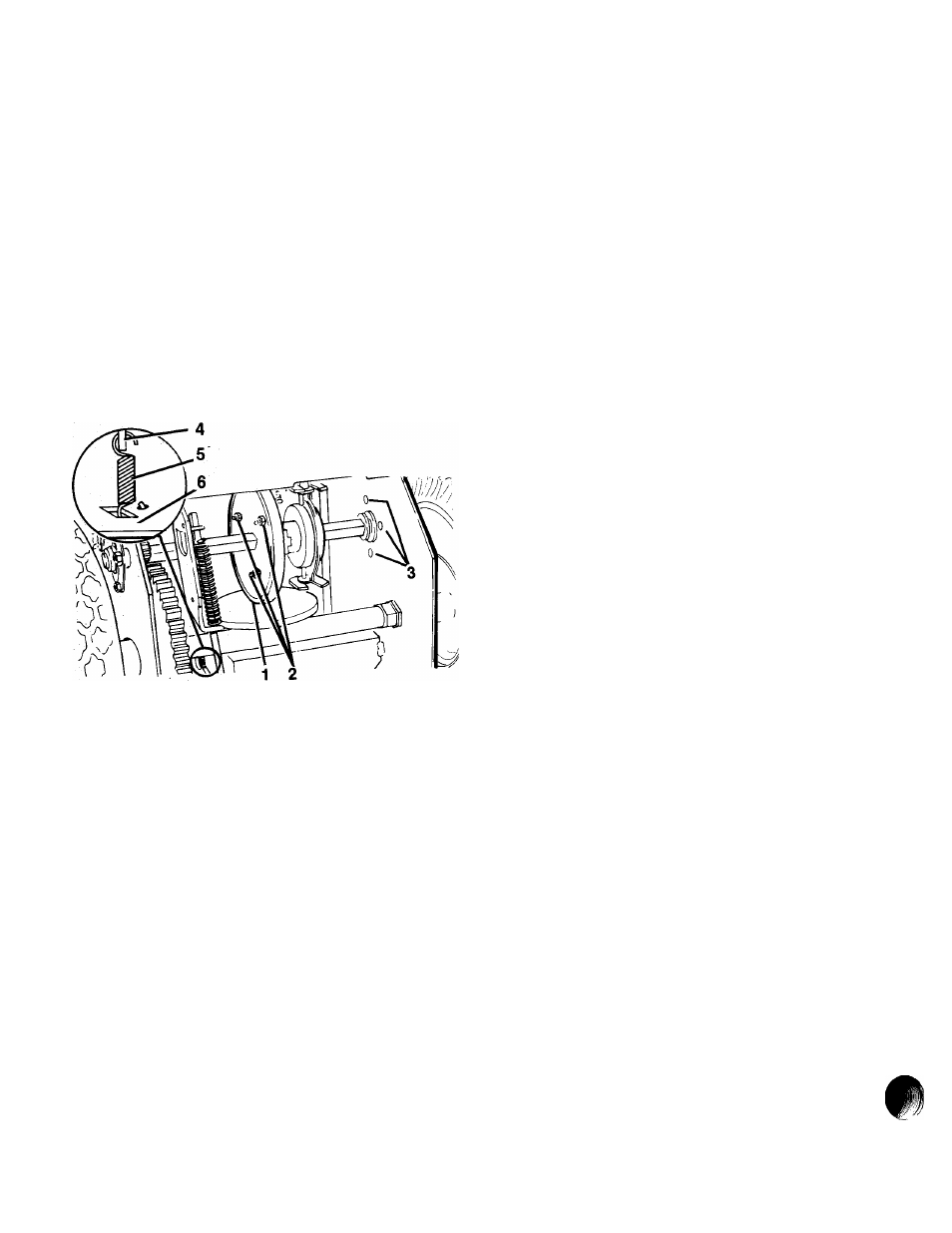

1. Friction Wheel

2. Cap Screw

3. Bearing Flange Screws

4. Clutch Fork

5. Extension Spring

6. Frame

Figure 5-3: Friction Wheel

5.2 Friction Wheel Removal

Tip unit onto housing and remove bottom

cover by removing four Cap screws.

Remove bearing flange screws on right hand

side of frame and remove bearing flange.

Remove hairpin cotter from traction clutch rod,

pull rod from clutch fork arm and tip up and out

of way.

Slide friction wheel assembly and hex shaft to

right until left end of hex shaft comes free of

left bearing. Slip assembly back to left and pull

forward out of frame.

Remove three cap screws securing friction

wheel to hub and remove friction wheel.

Secure new friction wheel onto hub with three

cap screws and torque cap screws to 8-10 foot

pounds.

Assemble using reverse procedure.

5.3 Drive Plate Removal

Remove drive plate return spring and bearing

flange from frame opposite axle gear, and

remove friction wheel.

Assemble using reverse procedure.

5.4 Clutch Fork Removal

Remove cap from outside of frame and cotter

pin from clutch fork rod. Remove clutch fork.

Inspect parts for wear or replacement and

assemble using reverse procedure.

NOTE: Position friction wheel hub in forks. Be

sure washers are in place on bearing flange

pins. Slide hex shaft to left and into left bear

ing with flat washers in position. Pinion gear

must mesh with large gear.

Remove auger/impeller housing and bottom

cover according to instructions in Auger/-

Impeller Section.

Remove attachment drive belt according to in

structions in Belt Drive Section and remove ex

tension springs from idlers.

Remove set screws from attachment pulley

hub and remove attachment pulley and hub.

Remove drive plate assembly, and remove fric

tion plate and bearing flange from assembly by

removing snap ring.

NOTE: Apply Loctite Anti-Sieze to hex end of

shaft before placing friction plate back onto

assembly.

Remove friction wheel assembly according to

instructions in Friction Wheel Removal Sec

tion and remove axle.

5-4