Sears 113.298141 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

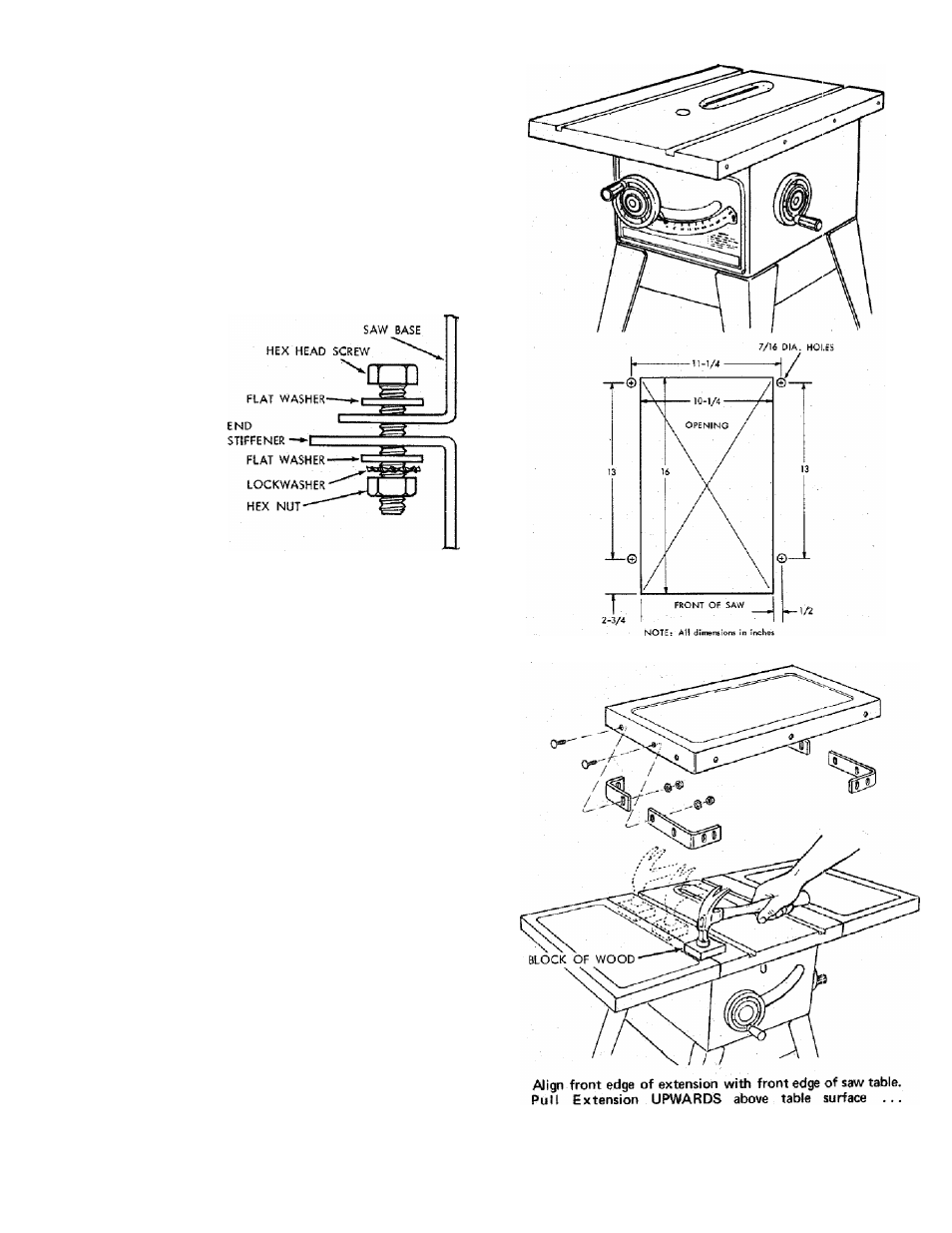

MOUNTING SAW

1. From among rtie loose parts, find the following

hardware:

4 Hex Head Screws, 5/16 - 18 x 1-1/4 in. long.

4 Hex Nuts, 5/16 -18 {approx, dia. of hole 5/16 in.)

4 Lockwashers, 5/16 in. External Type (approx, dia. of

hole, 5/16 in.)

8 Flat Washers, (dia. of hole 11/32 in.)

Z Place saw on legs so that holes in bottom of saw line up

with holes in top of legs.

3. install screws, washers, lockwashers and nuts as shown.

If you mount the saw on any other bench, make sure that

there is an opening in thejtop of the bench the same size as

the opening in the bottom of the saw so that the sawdust

can drop through. Recommended working height is 33 to

37 inches from the top of the saw table to the floor.

ATTACHING AND ASSEMBLING TABLE EXTENSIONS

If you received Table Extensions with your saw (two

furnished with Model No. 113.298031) or one furnished

with Model No. 113.298151) attach them at this time.

If you have only one Table Extension, it may be attached

to either side.

NOTE: When the Table Extension is attached to the left

side, it offers more support to the workpiece, especially

when crosscutting or mitering long boards. When attached

to the right side, it offers more support when cutting wide

panels.

If you attach the Extension to the left side, be sure to

construct the Auxiliary Fence/Work Support and Push

Block shown in "Basic Saw Operation" section.

1.

From among the loose parts find the following

hardware. NOTE: Double number of hardware If

assembling extensions for Model 113.298031.

2

Corner Support Brackets

2 Corner Stiffener Brackets

8 Truss Hd. Screws 1 /4-20 x 1

8

Ext. Lockwashers 1/4

8

Hex Nut 1/4-20

4

Hex Hd. Screws 5/16-18 x 1-1/4

4

Ext. Lockwasher 5/16

4

Hex Nut 5/16-18

Assemble brackets with hardware as listed.

Insert 5/16-18 X 1-1/4 in. long screws through holes in

EXTENSION

then

through

table.

Install

flat

washer,

lockwashers, and screw

on

the nuts . . . DO NOT

TIGHTEN.

SLIGHTLY TIGHTEN SCREWS using 1/2 in. wrench.

Using small block of hardwood and hammer, tap extension

DOWNWARDS at front, center & rear, until it is EVEN

with table surface .. . TIGHTEN SCREWS.