Mounting the motor – Sears 113.298141 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

16. Place RIP FENCE on table ...

CAREFULLY move it against blade so that it is parallel

to the blade, and just TOUCHES tips of saw teeth

tighten RIP FENCE LOCK KNOB

handle

.

17.

Insert

folded

paper

between

SPREADER

and

FENCE .. . hold spreader flat against fence .,. tighten

screws using 7/16 in. wrench. Now tighten Hex Hd.

Screws in Support.

18. To remove BLADE GUARD AND SPREADER, loosen

T H U M B S C R E W

. . .

DO

NOT

LOOSEN

OTHER

SCREWS.

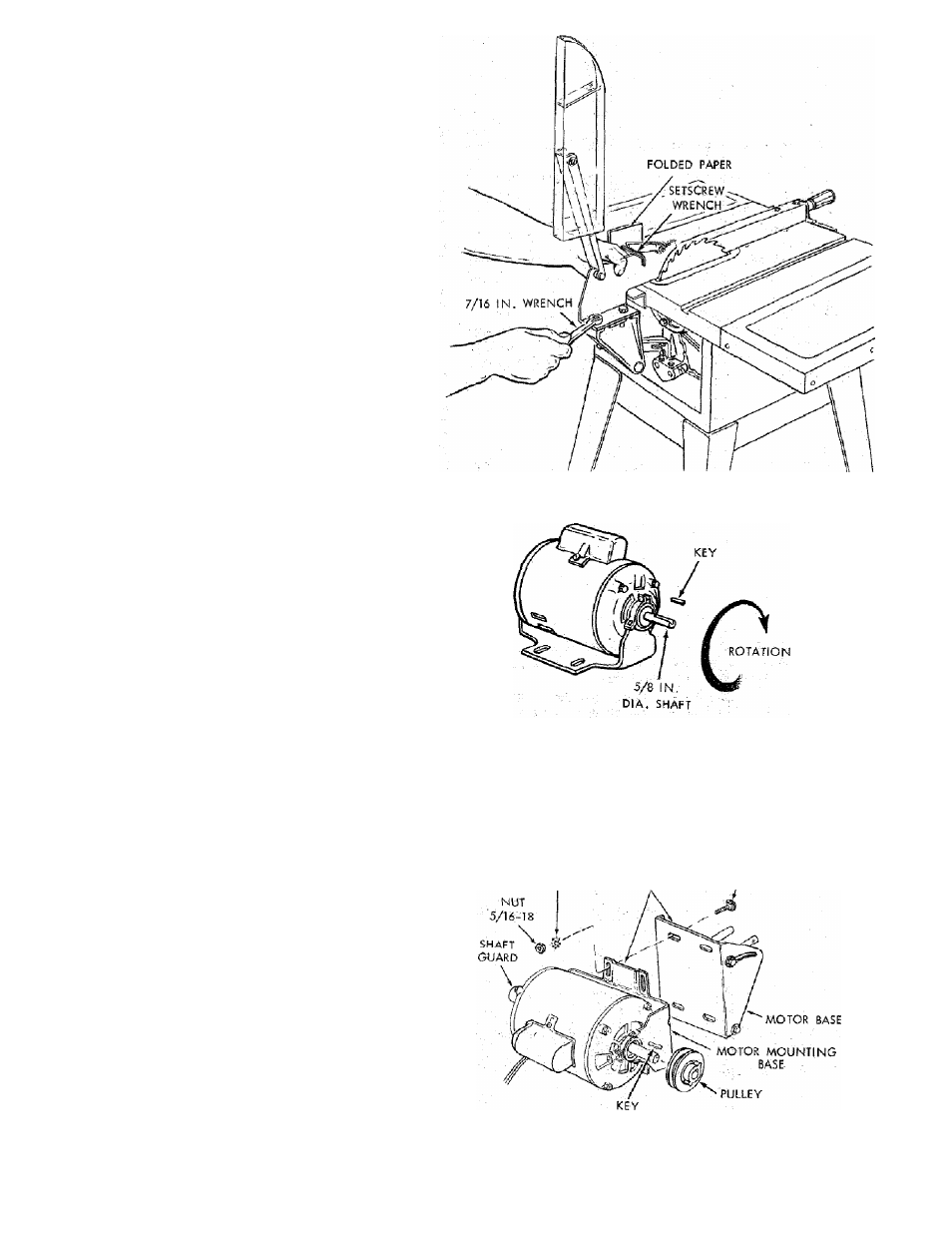

MOUNTING THE MOTOR

nctuded with Model 113.298031 and

NOTE: Motor is

113.298151.

CHECK MOTOR ROTATION

1. The motor must rotate CLOCKWISE when viewed from

the 5/8 in. shaft.

2. MAKE -SURE "KEY" IS REMOVED FROM SHAFT.

3. Place the motor on your workhench or on the floor.

4.

Plug the cord into a properly grounded outlet (See

"Motor Specifications and Electrical Requirements"

Section) Notice the rotation of the shaft. If it is not

turning CLOCKWISE, REMOVE the plug from the

outlet, and change the rotation of the motor according

to the instructions furnished with the motor.

WARNING: FOR YOUR OWN SAFETY, MAKE SURE

PLUG IS NOT CONNECTED TO POWER SOURCE

OUTLET WHEN CHANGING MOTOR ROTATION.

5.

From among the loose parts, find the following

hardware:

4 Carriage Bolts, 5/16 - 18

x

3/4 in. long

4 Hex. Nuts, 5 / 1 6 - 1 8

(approx, dia. of hole 5/16 in.)

4 Lockwashers, 5/16 in. External Type

(approx, dia. of hole 5/16 in.)

Remove Blade Guard and Spreader.

Place motor on MOTOR BASE ... insert bolts through

holes in base ... then through the motor. Install

lockwashers, and nuts.

Position motor so that edge of MOTOR FOOT and

MOTOR BASE are even .. . slide motor all the way to

the RIGHT ... tighten the four nuts.

9.

Loosen set screw in motor puHey using 5/32 in.

setscrew wrench. Slide pulley on shaft with HUB away

from motor. DO NOT TIGHTEN SETSCREW.

10. Install 3/16 in. square key (furnished with motor) in

grooves in pulley and motor shaft. DO NOT TIGHTEN

SETSCREW.

8

.

LOCKWASHER:

THESE TWO CARRIAGE BOLT

5/16 IN. EDGES EVEN 5/16-18 X 3/4 IN.

16