Motor specifications and electrical requirements – Sears 113.298141 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

R. DO NOT

remove small pieetes of cut-off material

that may become trapped inside the blade guard

while the saw is running. This could endanger your

hands or cause a kickback. Turn savy "OFF" and

wait until blade stops.

S. Use extra care when ripping wood that has a twisted

. grain or is twisted or bowed — it may rock on the

table and/or pinch the sawblade,

10. KNOW YOUB CUTTING TOOLS

A Dull, gummy,or improperly sharpened or set cutting

tools can cause material to stick, jam, stall the saw,

or kickback at the operator.

Minimize potential injury by proper cutting tool

and machine maintenance.

NEVER

ATTEMPT

TO

FREE

A

STALLED

SAWBLADE

WITHOUT

FIRST

TURNING

THE

SAW OFF.

B. Never use grindingi wheels, abrasive cut-off wheels,

friction wheels (metal slitting blades) wire wheels or

buffing wheels.

11. USE ONLY ACCESSORIES DESIGNED FOR THIS

SAW.

12. Crosscutting operations are more conveniently worked

and with greater safety if an auxiliary wood facing is

attached to the miter gauge using the holes provided.

However, the facing must not interfere with the proper

functioning of the sawblade guard.

13. Make sure the top of the arbor or cutting tool rotates

toward

you

when

standing

in

normal

operating

position. Also make sure the cutting tool, arbor collars

and arbor nut are installed properly. Keep the cutting

tool as low as possible for the operation being

performed. Keep ail guards in place whenever possible.

14. Do not use any blade or other cutting tool marked for

an operating speed less than 3450 RPM. Never use a

cutting tool larger in diameter than the diameter for

which the saw was designed. For greatest safety and

efficiency when ripping, use the maximum diameter

blade for which the saw is designed, since under these

conditions the spreader is nearest the blade.

15. Adjust table inserts flush with the table top. NEVER

operate the saw unless the proper insert is installed.

16. NEVER feed material into the cutting tool from the

rear of the saw. Ari accident and serious injury could

result.

17. THINK SAFETY.

Safety is a combination of operator common sense and

alertness at all times when the saw is being used..

18.

NOTE AND FOLLOW SAFETY INSTRUCTIONS

THAT APPEAR ON THE FRONT OF YOUR SAW.

DANGER

FOR YOUR OWN SAFETY

READ AND UNDERSTAND OWNER'S MANUAL

BEFORE OPERATING MACHINE:

1. WEAR SAFETY GOGGLES PER ANSI Z87.1 AT ALL

TIMES

2. USE SAW-BLADE GUARD FOR "THRU-SAWING"

3. KEEP HANDS OUT OF PATH OF SAWBLADE

4. USE A "PUSH-STICK" WHEN REQUIRED

5. KNOW HOW TO AVOID "KICKBACKS"

6. DO NOT PERFORM OPERATIONS "FREEHAND"

7. NEVER REACH AROUND OR OVER SAW BLADE

19.

WARNING:

DO

NOT

ALLOW

FAMILIARITY

(GAINED FROM FREQUENT USE OF YOUR SAW)

TO

BECOME

COMMONPLACE.

-

A L W A Y S

REMEMBER THAT A CARELESS FRACTION OF A

SECOND IS SUFFICIENT TO INFLICT SEVERE

INJURY.

20. WARNING! THE 2-1/2" SAW PULLEY AND THE

2-1/2" MOTOR PULLEY FURNISHED, WILL RUN

THE

BLADE

AT

APPROXIMATELY

3450

RPM

WHEN USED WITH A 3450 RPM MOTOR. NEVER

SUBSTITUTE THESE PULLEYS TO INCREASE THIS

SPEED BECAUSE IT COULD BE DANGEROUS.

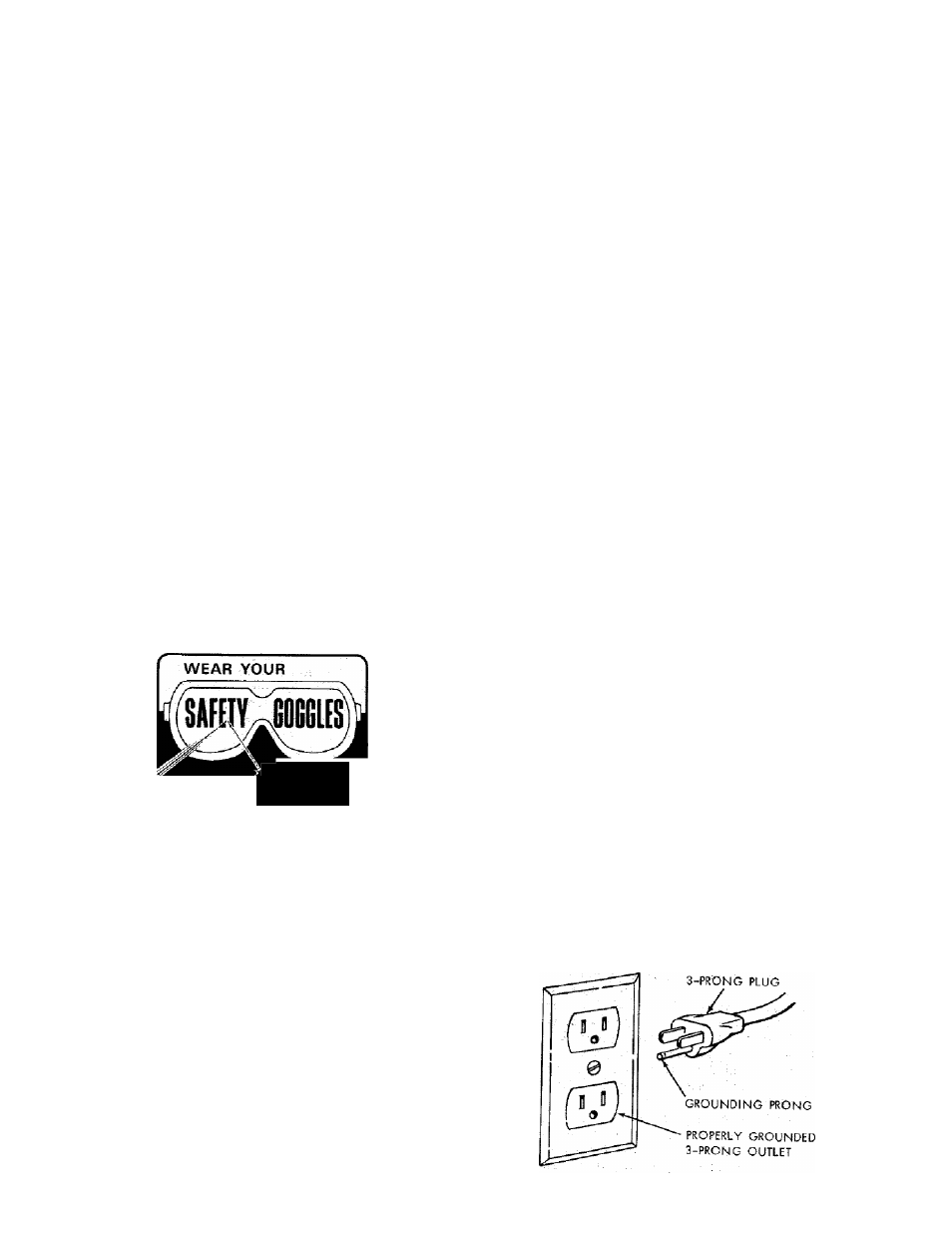

\ FORESIGHT IS

BETTER THAN

NO SIGHT

The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety goggles complying

with ANSI Z87.1 (shown on Package) before commencing

power tool operation. Safety Go®les are available at Sears

retail or catalog stores.

MOTOR SPECIFICATIONS AND ELECTRICAL REQUIREMENTS

This saw is designed to use a 3450 RPM motor only. Do not

use any motor that runs faster than 3450 RPM. It is wired

for operation on 110-120 volts, 60 Hz., alternating current.

IT MUST NOT BE CONVERTED TO OPERATE ON 230

V O L T S .

E V E N

T H O U G H

S O M E O F T H E

RECOMMENDED MOTORS ARE DUAL VOLTAGE.

Changing tn 230 volt will not conservé energy and requires

changing the power cord plug.

The outlet in the switch box will accept either a T5 amp. or

a 20 amp. motor plug.

RECOMMENDED CRAFTSMAN MOTORS FOR USE ON

THIS SAW.

CONNECTING TO POWER SOURCE OUTLET

This saw must be grounded while in use to protect the

operator from electrical shock.

jf power cord is worn or cut, or damaged in any way, have

it replaced immediately.

If your saw is for use on less than 150 volts it has a plug

that looks like below.

H.P.

R.P.M.

Volts Catalog No.

3450

3450

110-120

110-120

1217

1220

CAUTION: Do not use blower or washing machine motors

or any motor with an automatic reset overload protector as

their use may be hazardous.