Operating sequence, Table 25 — evaporator-fan motor data – Carrier 48TJ016-028 User Manual

Page 36

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

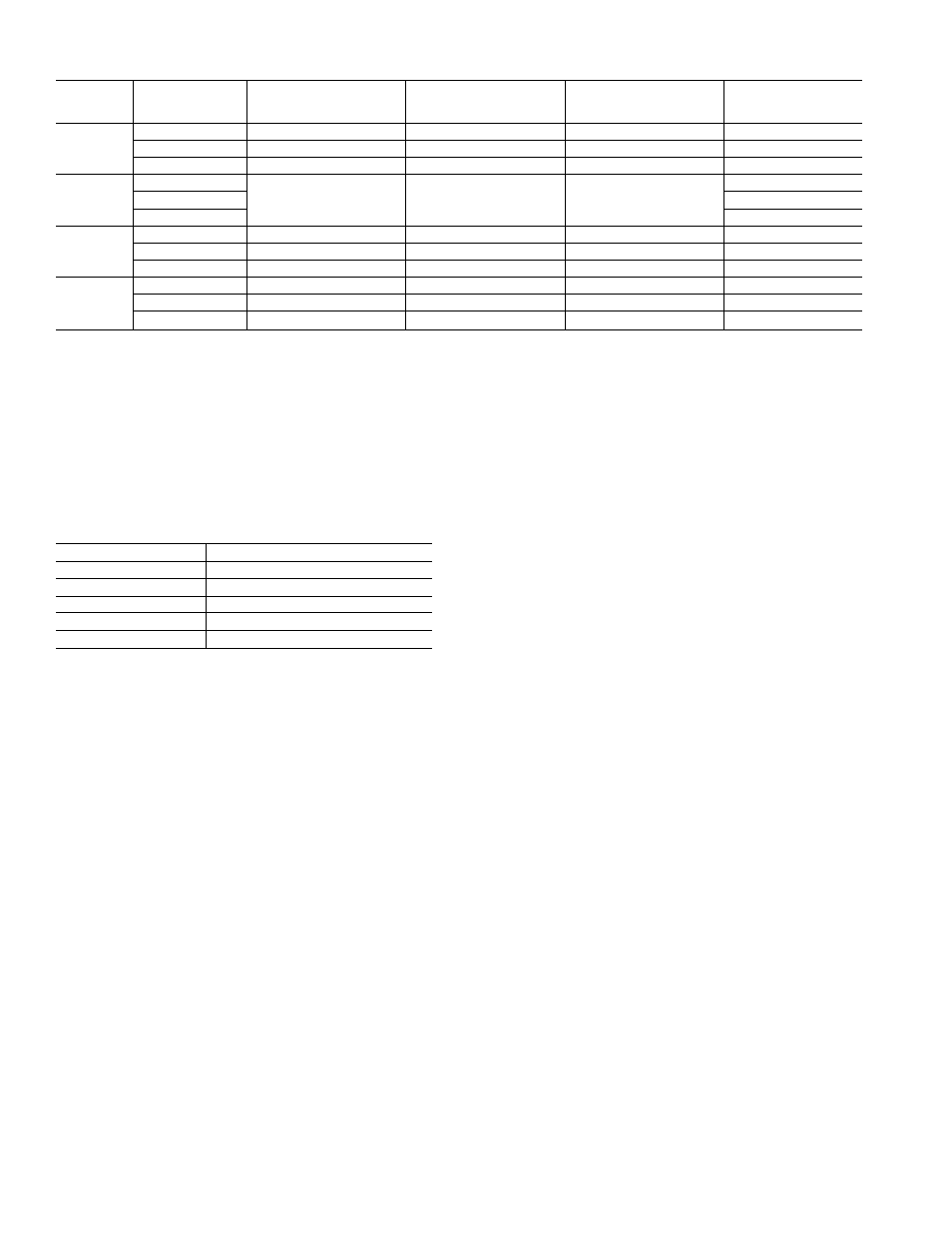

Table 25 — Evaporator-Fan Motor Data

UNIT

48TJ

UNIT

VOLTAGE

MAXIMUM

ACCEPTABLE

CONTINUOUS ВНР*

MAXIMUM

ACCEPTABLE

CONTINUOUS BkW*

MAXIMUM

ACCEPTABLE

OPERATING WATTS

MAXIMUM

AMP DRAW

016

208/230

4.25

3.17

3,775

10.5

460

4.25

3.17

3,775

4.8

575

3.45

2.59

3,065

3,9

020

208/230

5.90

4.40

5,180

15.8

460

7.9

575

6,0

024

208/230

8.70

6.49

7,915

22.0

460

9.50

7.08

8,640

13.0

575

8.70

6.49

7,915

10.0

028

208/230

10.20

7.61

9,510

28.0

460

11.80

8.80

11,000

14.6

575

10.20

7.61

9,510

13.0

LEGEND

ВНР

— Brake Horsepower

BkW

— Brake Kilowatts

‘Extensive motor and eleclricai testing on these units ensures that the fuii horsepower (brake kiiowatt)

range of the motors can be utilized with confidence. Using your fan motors up to the horsepower (brake

kilowatt) ratings shown in this table will not result in nuisance tripping or premature motor failure. Unit

warranty will not be affected.

NOTE: All indoor-fan motors 5 hp and larger meet the minimum efficiency requirements as established by

the Energy Policy Act of 1992 (EPACT) effective October 24, 1997.

Table 26 — Evaporator-Fan Motor Efficiency

UNIT 48TJ

MOTOR EFFICIENCY (%)

016 (3.0 Hp)

81.7

016(3.7 Hp)

85,8

020 (5 Hp)

87.5

024 (7.5 Hp)

88.5

028 (10 Hp)

89,5

NOTE: All indoor-fan motors 5 hp and larger meet the minimum effi

ciency requirements as established by the Energy Policy Act of 1992

(EPACT) effective October 24, 1997.

CONDENSER-FANS AND MOTORS Condenser fans

and motor's are factoi-y set. Refer to Condenser-Fan Adjustment

section (page 42) as requii'ed. Be sure that tans I'otate in the

pixrper direction.

RETURN-AIR FILTERS — Check that coi'rect filter's ar'e

installed in filter tracks (see Table I). Do not oper'ate unit with

out retur n-air filter s.

OUTDOOR-AIR INLET SCREENS — Outdoor-air inlet

scr'eens must be in place befor'e oper'ating unit.

GAS HEAT — Ver'ify gas pr'essures befor'e tur'ning on heat as

follows:

1. Turn off r"nanual gas stop.

2. Connect pr'essur'e gage to supply gas pressure tap (see

Fig. 1.3).

3. Connect pressur'e gage to r'nanifold pr'essur'e tap on gas

valve.

4. Turn on ruanual gas stop and set theranostat to HEAT

position. Adjust set point to several degr'ees above the

curr'ent r'oom teruper'atun; to ensur'e a heat demand. After

the unit has tarn for several minutes, verify that incoming

pressure is 5.5 in. wg or gr'eater', and that the manifold

pressure is 3.3 in. wg. If manifold pr'essure must be ad

justed, refer to Gas Valve Adjustment section on page 43.

.3. After unit has been in oper ation for 5 minutes, check tem

perature rise acr'oss the heat exchangers. See unit infor'-

rnative plate for corr'ect rise limits of the heat supplied.

Air quantities may need to be adjusted to bring the actual

rise to within the allowable limits.

Operating Sequence

COOLING, UNITS WITHOUT ECONOMIZER — Wlien

ther'rnostat calls for cooling, ter'rnimils G and Y1 ar'e ener'gized.

The indoor (evaporator') fan contactor (IFC), cornpr'essor con

tactor no. 1 (Cl) and outdoor'-fan contactor (OFC) an: ener'

gized, and evapor'ator-fan motor', cornpnsssor' no. 1, and both

condenser' fans star!. Tlie condenser'-fan motor's rirn continuous

ly while unit is cooling. If the thermostat calls for a second stage

of cooling by ener'gizing Y2, cornpr'essor contactor no. 2 (C2) is

energized and compressor no. 2 starts.

When the thermostat is satisfied, Cl and C2 ше deener

gized and tlie cornpr'essors and outdoor (condenser) fan motors

(OFM) shut off. After a 30-second delay, the indoor (evapora

tor') fan motor (IFM) shuts off If the ther'rnostat fan selector

switch is in the ON position, tlie evapor'ator-fan motor will ran

continuously.

HEATING. UNITS WITHOUT ECONOMIZER ^ When

the thermostat calls for heating, ter'rninal W1 is ener'gized. In

or'der to pr'event ther'rnostat shorf-cycling, the unit is locked

into the Heating mode for at least 1 minute when W1 is ener'

gized. The induced-dr'aft motor (IDM) is then ener'gized and

the bur'ner ignition sequence begins. The indoor (evapor'ator')

fan motor (IFM) is ener'gized 4.5 seconds after a flame is

ignited. On units equipped for two stages of heat, when addi

tional heat is needed, W2 is energized and the high-fu'e sole

noid on the main gas valve (MGV) is ener'gized. When the

ther'rnostat is satisfied and W1 and W2 ar'e deener'gized, the

IFM stops after a 4.5-second tirne-off delay.

COOLING. UNITS WITH ECONOMI$ERIV ^ When tree

cooling is not available, tlie compressor's will be controlled by

the zone thermostat. When tree cooling is available, the

outdoor-itir damper is modulated by the EconoMi$er'IV contr'ol

to pr'ovide a .50 to 55 F supply-air temperature into the zone. As

the supply-air ternper'ature fluctuates above 55 or below 50 F,

the damper's will be modulated (open or close) to br'ing the

supply-air ternperatun: back within the set point limits.

For EconoMi$er'IV oper'ation, there must be a ther'rnostat

call for the fan (G). This will move Ше damper to its minimum

position during the occupied mode.

.36