Fig. 23, Motormaster v control, A 0j|^||y|q – Carrier 48TJ016-028 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MOTORMASTER®

V

CONTROL

INSTALLATION

(48TJ024,028 UNITS)

Install Lield-Fabricated Wind Baffles — Wind baffles must

be field-fabricated for all units to ensure proper cooling cycle

operation at low ambient temperatures. See Fig. 21 for baffle

details. Use 20-gage, galvanized sheet metal, or similar

coito

-

sion-resistant metal for baffles. Use field-supplied screws to at

tach baffles to unit. Screws should be ‘A-in. diameter and

5/s-in. long. Drill required screw holes for mounting baffles.

A 0j|^||Y|Q||

To avoid dmnage to the refrigerant coils and electrical com

ponents, use recommended screw sizes only. Use cru'e

when diilling holes.

FR<3M FUSE BLOCK

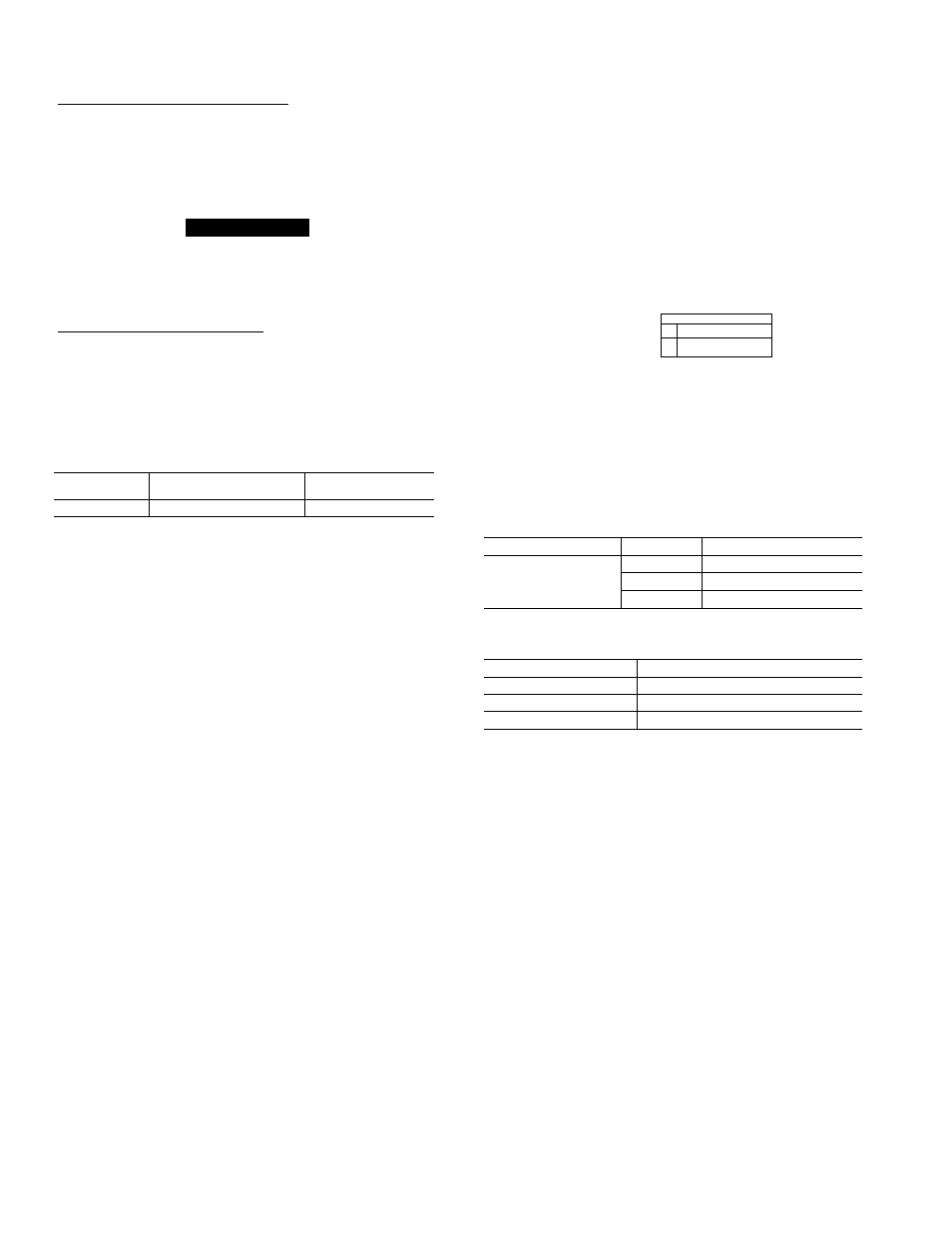

Install Motormaster V Controls — Tlie Motormaster V

(MMV) control is a motor speed control device which adjusts

condenser fan motor speed in response to declining liquid re

frigerant pressure. A properly applied Motormaster V control

extends the operating range of air-conditioning systems and

permits operation at lower outdoor ambient temperatures.

Tlie minimum iunbient temperatures at which the unit will

operate are:

TEMPERATURE OPERATING LIMÌTS — F°

standard

Unit with

Unit with

Unit

Low Ambient Kit

MMV Control

40

25

-20

To operate down to the ambient temperatures listed,

Motomiaster V controls (Fig. 23) must be added. Field-fabricat

ed and installed wind baffles iu'e also required for iill units (see

Fig. 21). The Motormaster V control permits operation of the

unit to an ambient temperature of-20 F. Tlie control regulates the

speed of 3-phase fan motors that aie compatible with the control.

Tliese motors are factoiy installed.

See Table 6 for the Motormaster V control accessoiy pack

age usage. Table 7 shows applicable voltages and motors.

Replacement of motor or fan blade IS NOT REQUIRED ON

CURRENT PRODUCTION UNITS since the control is

compatible with the factoiy-installed fan motors. Only field

wiring control is required

Install the Motormaster V control per instiuctions supplied

with accessoiy.

Ó O Ò O Ó

TO PRESSURE^

TRANSDUCER

U

U L3

12 13Ai

256

I

n

io/-\

IflrtDfVÌÓnrTnhDnrvnfìDITri

/;n 7О О3 B-

O Q O O O

C E [ 3

G

5

o

Fig. 23

TO MOTOR(S)

Motormaster V Control

Table 6 — Motormaster V Control Package Usage

UNIT

VOLTAGE

ITEM DESCRIPTION

208/230

CRLOWAIVIB015A00

48TJ024,028

460

CRLOWAÌVIB016A00

575

CRLOWAW1B017A00

Table 7 — Applicable Voltages and Motors

VOLTAGE

COMPATIBLE MOTOR

208/230-3-60

HD52AK654

460-3-60

HD52AK654

575-3-60

HD52GE576

16