Fig. 29 — differential enthalpy control wiring, 1 ° о 1 1 о, O o o – Carrier 48TJ016-028 User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

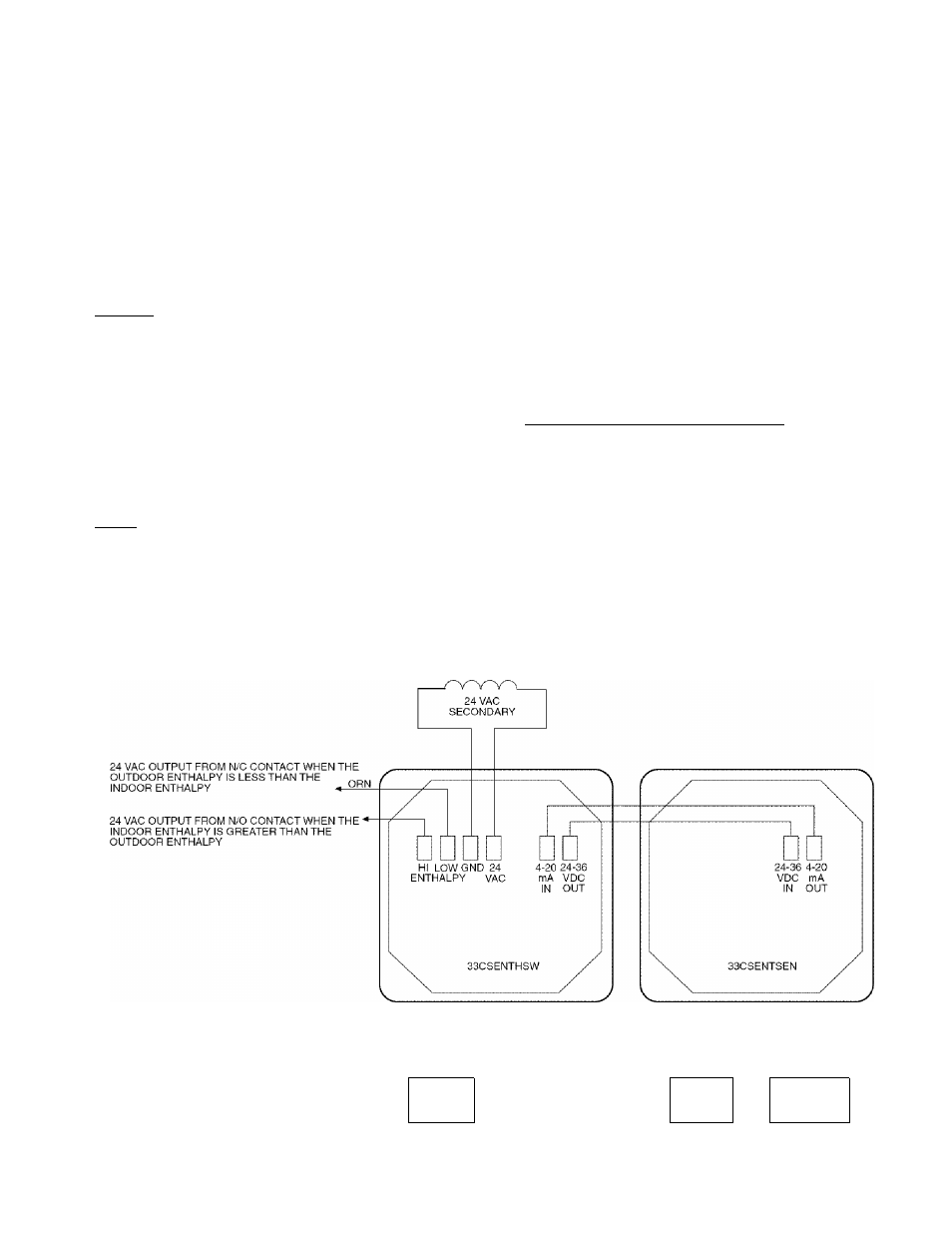

DIFFERENTIAL ENTHALPY CONTROL (Fig. 29) —

Differentiiil enthalpy control requires both an enthiilpy switch/

receiver

(.33CSENTHSW)

and

an

enthtJpy

sensor

(33CSENTSEN), The enthalpy switch/receiver is mounted in

the outdoor air inlet and calculates outdoor air enthalpy. The

enthalpy sensor is mounted in the return airstream and ciilcu-

lates the enth;ilpy of the indoor air.

Tire enthalpy switclr/receiver energizes the HI Enthalpy re

lay output when the outdoor enthalpy is greater tlran tire indoor

enthalpy. Tire LOW Entlralpy terminal is energized when the

outdoor entlralpy is lower than the indoor enthalpy. Tire relay

output is wired to the unit economizer which will open or close

depending on the output of the switch.

NOTE; Tire enthalpy calculation is done using an average alti

tude of 1000 ft above sea level.

Mounting — Mount the enthalpy switch/receiver in a location

where tire outdoor air can be sampled (such as the outdoor air

intitke). Tire enthalpy switch/receiver is not a NEMA 4 enclo

sure and should be mounted in a location that is not exposed to

outdoor elements such as rain, snow, or direct sunlight. Use

two field-supplied no. 8 x Yr-in. ТЕК screws. Insert the screws

through the holes in the sides of the enthalpy switclr/receiver.

Mount the enthalpy sensor in a location where the indoor air

can be siunpled (such as the return air duct). Tire enthalpy

sensor is not a NEMA 4 enclosure and should be mounted in a

location that is not exposed to outdoor elements such as rain or

snow. Use two field-supplied no. 8 x V

4

-in. ТЕК screws. Insert

the screws tlrrough the holes in tire sides of the enthalpy sensor.

Wiring — Carrier recommends the use of 18 to 22 AWG

twisted pair or shielded cable for all wiring. All connections

must be made with Vr-in. female spade connectors.

The PremierLink'f’'* board provides 24-vac to power the

enthalpy switch/receiver. Connect the GND and 24 VAC termi

nals on the enthalpy switclr/receiver to the terminals on

tire transformer. On some applications, tire power from the

economizer htu'ness can be used to power the enthalpy switch/

receiver. To power the enthalpy switch/receiver from the

economizer harness, connect power of the enthalpy switch/

receiver to the red and brown wires (1 and 4) on the econo

mizer harness.

Connect the LOW Enthalpy terminal on the enthalpy

switch/receiver to J4 — pin 2 of the PremierLink control on the

HVAC unit. The switch can be powered through the Premier

Link control board if desired. Wire tlie 24VAC terminal on the

enthidpy switcli/receiver to J4 — pin 1 on the PremierLink

control. Wire the GND terminal on the enthalpy switch/

receiver to J1 — pin 2 on the PremierLink control. The HI

Enthalpy terminal is not used. See Fig. 28.

Connect the 4-20 mA IN terminal on the enthalpy switch/

receiver to the 4-20 mA OUT terminal on the return air en-

tlialpy sensor. Connect the 24-36 VDC OUT terminiil on the

enthalpy switcli/receiver to the 24-36 VDC IN terminal on the

return air enthalpy sensor. See Fig. 29.

Enthalpy Switch/Receiver Jumper Settings — There are two

jumpers. One jumper determines the mode of the entlialpy

switch/receiver. The other jumper is not used. To access the

jumpers, remove the 4 screws holding the cover on the

enthalpy switcli/receiver and then remove the cover. Tlie fac-

toiy settings for the jumpers £U'e M1 and OFF.

The mode jumper should be set to M2 for differential en-

tlialpy control. The factoiy test jumper should remain on OFF

or the enthalpy switch/receiver will not calculate enthalpy.

120 VAC

LINE VOLTAGE

LEGEND

N/C

—

Normally

Closed

N/O

— Normally Open

JUMPER SETTINGS FOR 33CSENTHSW

1 °

о 1

1 о

I

o o o

o o o

JUMPER SETTINGS FOR 33CSENTSEN

0 О cn

^

о О

о

1

-S?

r-P

Fig. 29 — Differential Enthalpy Control Wiring

■ o o

■ o o o

B o o

1 o o o

21