Installation, Step 1 — provide unit support, Installation -31 – Carrier 48TJ016-028 User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INSTALLATION

Inspect unit for transportation danage. If cktmage is found,

file claim with transportation agency.

Step 1 — Provide Unit Support

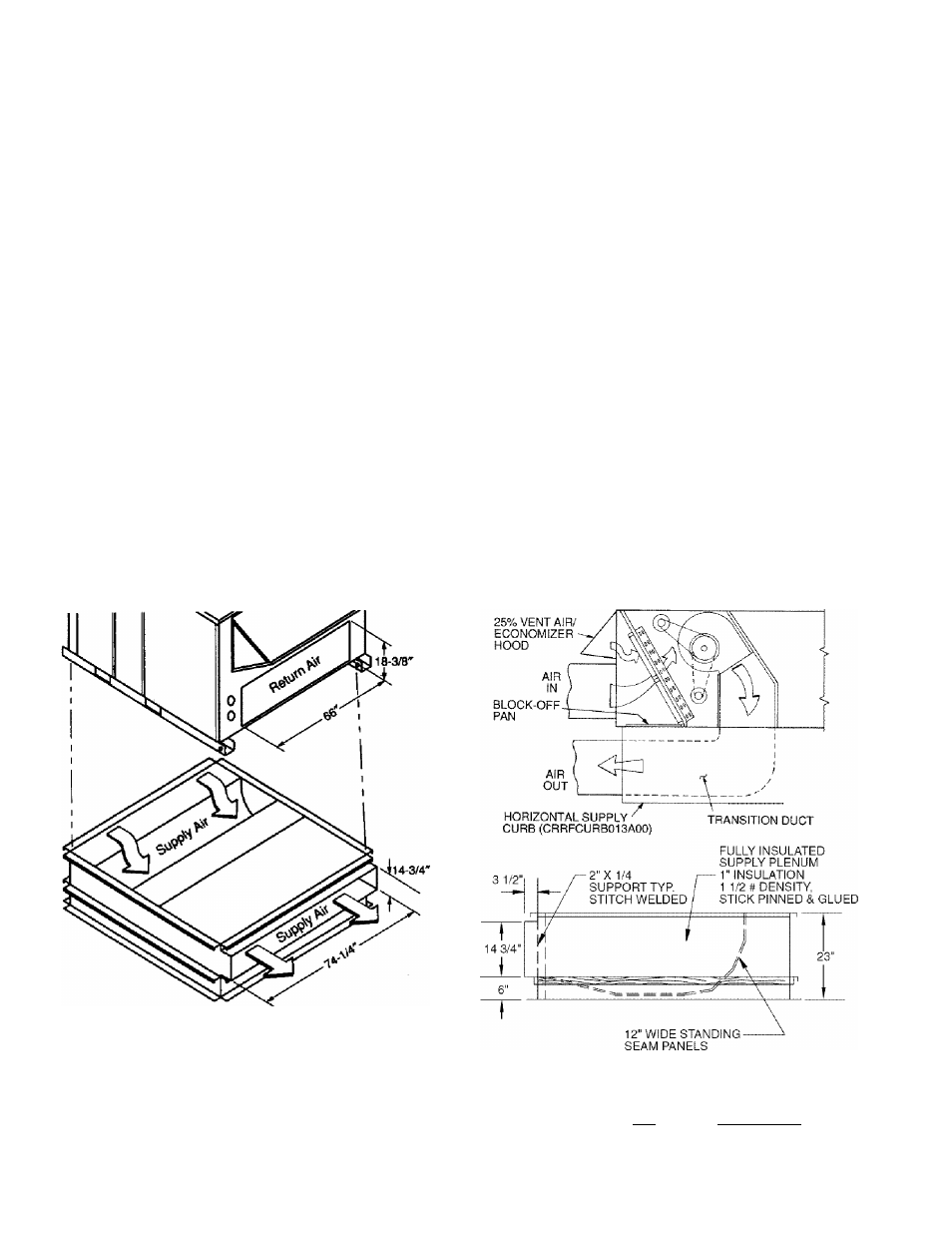

ROOF CURB — Assemble and install accessoiy roof curb or

horizontiil adapter roof cuifi in accordance witli instinctions

shipped with this accessoiy. See Fig. 1 and 2. Install insulation,

cant strips, roofing, and counter flashing as shown. Ductwork

can be installed to roof curb or horizontal adapter roof curb be

fore unit is set in place. Curb or adapter roof curb should be

level. Tills is necessaiy to permit unit drain to function proper

ly. Unit leveling tolerance is ± Vu, in. per linear ft in any direc

tion. Refer to Accessoiy Roof Curb or Horizontal Adapter

Roof Curb Installation Instmctions for additional information

as required. When accessoiy roof curb or horizontal adapter

roof curb is used, unit may be installed on class A, B, or C roof

covering material.

IMPORTANT: The gasketing of the unit to the roof curb

or adapter roof curb is critical for a watertight setil.

InstiJI gasket with the roof curb or adapter as shown in

Fig. 2. Improperly applied gasket can also result in air

leaks and poor unit performance.

ALTERNATE UNIT SUPPORT ^ When the curb or adapter

cannot be used, install unit on a noncombustible surface. Sup

port unit with sleepers, using unit curb support area. If sleepers

cannot be used, support long sides of unit with a minimum of 3

equally spaced 4-in. x 4-in. pads on each side.

Step 2 — Rig and Place Unit — Do not di'op unit;

keep upright. Use spreader biu's over unit to prevent sling or

cable diimage. Rollers may be used to move unit across a roof.

Level by using unit frame as a reference; leveling tolerance is

±V](i in. per linear ft in any direction. See Fig. 3 for additional

information. Unit operating weight is shown in Table 1.

Four lifting holes are provided in ends of unit base rails as

shown in Fig. 3. Refer to rigging instmctions on unit.

POSITIONING — Maintain clearance, per Fig. 4 and 5,

around and above unit to provide minimum distance from

combustible materials, proper airflow, and service access.

Do not install unit in an indoor location. Do not locate unit

air inlets near exhaust vents or other sources of contaminated

air. For proper unit operation, adequate combustion and venti

lation ail' must be provided in accordance with Section 5.3 (Air

for Combustion and Ventilation) of the National Fuel Gas

Code, ANSI Z223.1 (American National Standards Institute).

Although unit is weatlierproof, guard against water from

higher level mnoff and overhangs.

Locate mechanical di'aft system flue assembly at least 4 ft

from any opening through which combustion products could

enter the building, and at least 4 ft from any adjacent building.

When unit is located adjacent to public walkways, flue assem

bly must be at least 7 ft above grade.

ROOF MOUNT — Check building codes for weight distri

bution requirements. Unit operating weight is shown in

Table 1.

Instructions continued cm page 9.

NOTE:

CRRFCURB013A00

is

a

fuliy

factory

prsassembied

hori

zontal adapter and includes an insulated transition duct. The pres

sure drop through the adapter curb is negligible.

For horizontal return applications; The power exhaust and baro

metric relief dampers must be installed in the return air duct.

ACCESSORY

PACKAGE NO.

CRRFCURB013AOO

CURB

HEIGHT

(584)

DESCRIPTION

Pre-Assembled, Roof Curb,

Horizontal Adapter

Fig. 1 — Horizontal Supply/Return Adapter Installation