1bibliography, 2introduction – Winco DSE71xx Series User Manual

Page 5

DSE Model 71xx Series Control & Instrumentation System Mk2 Operators Manual

Part No. 057-113 71xx Series OPERATING MANUAL ISSUE 2 12/08/2010 ADM

5

1

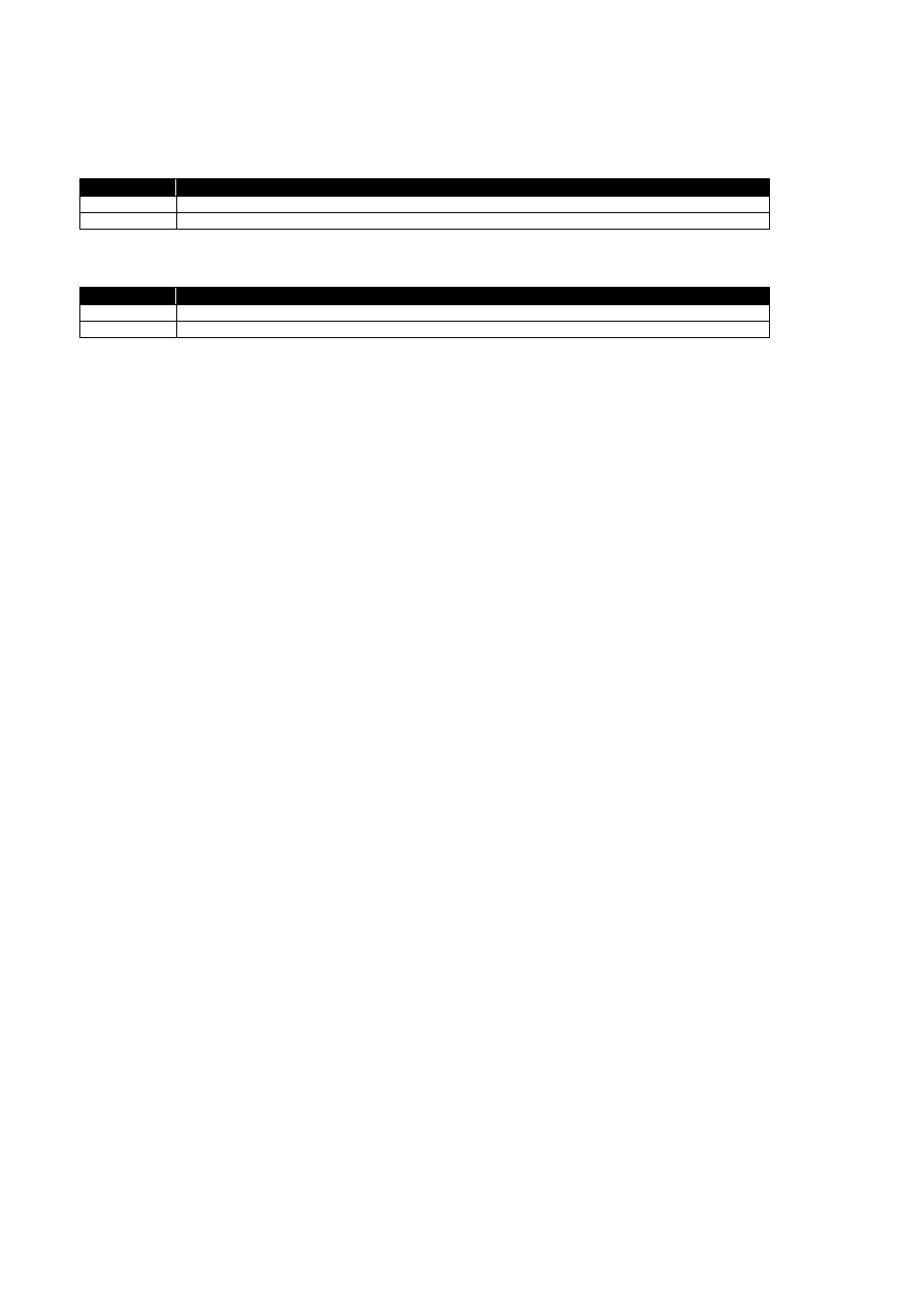

BIBLIOGRAPHY

1.1

INSTALLATION INSTRUCTIONS

DSE PART

DESCRIPTION

053-080

7110 installation instructions

053-081

7120 installation instructions

1.2

MANUALS

DSE PART

DESCRIPTION

057-004

Electronic Engines and DSE wiring

057-117

DSE71xx Config Suite Manual

2

INTRODUCTION

This document details the installation and operation requirements of the DSE71xx, part of the DSEUltra® range of products.

DSE6100 series modules are not covered in this document.

The manual forms part of the product and should be kept for the entire life of the product. If the product is passed or supplied to

another party, ensure that this document is passed to them for reference purposes.

This is not a controlled document. You will not be automatically informed of updates. Any future updates of this document will

be included on the DSE website at www.deepseaplc.com

The DSE 71xx series module has been designed to allow the operator to start and stop the engine/generator, and if required,

transfer the load.

The user also has the facility to view the system operating parameters via the LCD display.

The DSE 71xx module monitors the engine, indicating the operational status and fault conditions, automatically shutting down

the engine and giving a true first up fault condition of an engine failure. The LCD display indicates the fault.

The powerful microprocessor contained within the module allows for incorporation of a range of enhanced features:

•

Text based LCD display

•

True RMS Voltage monitoring with 3 phase generator sensing Engine parameter monitoring.

•

Fully configurable inputs for use as alarms or a range of different functions.

•

Engine ECU interface to electronic engines

•

Magnetic pickup interface for engine only applications

Using a PC and the 71xx series configuration software allows alteration of selected operational sequences, timers and alarm

trips.

Additionally, the module’s integral fascia configuration editor allows full adjustment of all this information.

A robust plastic case designed for front panel mounting houses the module. Connections are via locking plug and sockets.